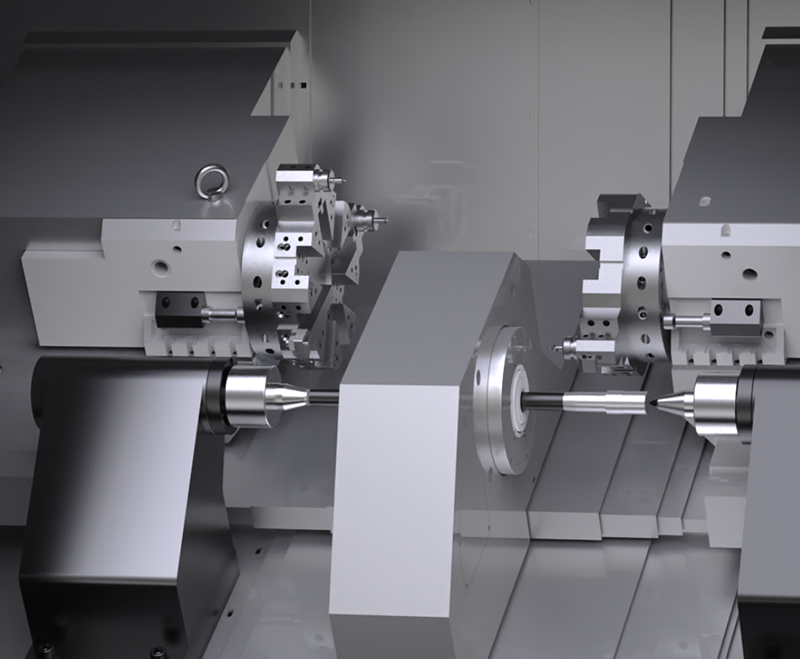

Li-lathe tsa CNC tse nang le li-spindle tse peliKe lisebelisoa tsa bohlokoa tlhahisong ea sejoale-joale, ka botsitso ba ts'ebetso le ts'ebetso e nepahetseng e amang katleho ea tlhahiso le boleng ba sehlahisoa ka kotloloho. Ka hona, tlhokomelo ea letsatsi le letsatsi ea mechine ena ke ea bohlokoa ka ho khetheha. Ka tlhokomelo e utloahalang, hase feela hore nako ea bophelo ea thepa e ka atolosoa, empa ho nepahala ha eona ho sebetsa le botsitso ba ts'ebetso ho ka boela ha netefatsoa, kahoo ho matlafatsa tlhahiso ea tlhahiso le ho fokotsa litšenyehelo tsa tlhokomelo.

Bohlokoa ba Tlhokomelo ea Letsatsi le Letsatsi

1.Ho Eketsa Nako ea Bophelo ea Thepa

Li-lathe tsa CNC tse nang le li-spindle tse peli li na le maemo a fapaneng a ho khathala le tšusumetso ho likarolo tsa tsona nakong ea ts'ebeliso. Ho hloekisa khafetsa, ho tlotsa le ho hlahloba ho ka thusa ho tseba le ho rarolla mathata a ka bang teng, joalo ka litataiso tse senyehileng le li-fasteners tse hlephileng, ho thibela mathata a manyane hore a se ke a fetoha liphoso tse kholo le ho lelefatsa bophelo bohle ba lisebelisoa ka nepo.

2.Ho netefatsa ho nepahala ha lisebelisoa

Ho nepahala ha tšebetso eaHabeli Spindle CNC latheke sesupo sa bohlokoa sa tšebetso ea bona. Ho nepahala ha likarolo tsa bohlokoa joalo ka litataiso le likurufu tsa loto li ama ka kotloloho ho nepahala ha litekanyo le boleng ba bokaholimo ba likarolo tse sebetsitsoeng. Ka tlhokomelo ea letsatsi le letsatsi, joalo ka ho hloekisa lithōle khafetsa ho tsoa ho batataisi le likurufu tsa loto tse tlotsang, likarolo tsena li ka boloka ho nepahala ha tsona, ho etsa bonnete ba hore likarolo tse lokisoang li fihlela litlhoko tsa moralo.

3.Ho ntlafatsa botsitso ba ts'ebetso le ho ts'epahala

Nakong ea ts'ebetso, li-lathe tsa CNC tse nang le li-spindle tse peli li hloka ts'ebetso e hokahaneng ea litsamaiso tse fapaneng tse fapaneng, ho kenyeletsoa lisebelisoa tsa motlakase, tse pholisang le tsa ho tlotsa. Ho hloleha hofe kapa hofe ho li-subsystem tsena ho ka lebisa ho theohe ha lisebelisoa, ho ama linako tsa tlhahiso. Tlhokomelo ea kamehla, joalo ka ho lekola likhokahano tsa lithapo, lisebelisoa tsa ho hloekisa tse pholileng, le ho nkela lilubricant sebaka, ho netefatsa hore li-subsystem tsohle li sebetsa hantle, ho matlafatsa botsitso le ts'epahalo ea lisebelisoa.

4.Ho fokotsa Litefiso tsa Phoso le Litšenyehelo tsa Tlhokomelo

Tlhokomelo ea kamehla e ka lemoha le ho rarolla liphoso tse ka bang teng hang-hang, ho thibela tahlehelo ea tlhahiso ka lebaka la ho se sebetse ha thepa. Ho feta moo, kemiso ea tlhokomelo e reriloeng hantle e ka eketsa potoloho e kholo ea ntlafatso ea thepa, ea fokotsa litšenyehelo tsa tlhokomelo.

Mekhoa e Khethehileng ea Tlhokomelo

1.Ho Hloekisa Kamehla le ho Lubrication

Tlhoekiso ea Tataiso: Hloekisa litataiso khafetsa ho boloka boreleli le ho nepahala ha tsona.

Lead Screw Lubrication: Lubricate screws ka linako tsohle ho fokotsa khohlano le ho boloka ho nepahala le nako ea bophelo.

Tlhahlobo ea Sistimi ea Lubrication: Kamehla hlahloba boemo ba oli le boleng ba sistimi ea lubrication ho netefatsa hore e sebetsa ka mokhoa o tloaelehileng.

2.Tlhahlobo ea Tsamaiso ea Motlakase

Tlhokomeliso ea Khokelo ea Lithapo: Kamehla hlahloba likhokahano tsa lithapo ho netefatsa hore li bolokehile.

Tlhahlobo ea Karolo ea Motlakase: Kamehla hlahloba likarolo tsa motlakase, tse kang li-relay le li-contactor, ho netefatsa hore li sebetsa hantle.

3.Cooling System Maintenance

Tlhahlobo ea Pholiso: Hlahloba mocheso le boemo ba sepholisa khafetsa ho netefatsa hore sistimi ea ho pholisa e sebetsa ka mokhoa o tloaelehileng.

Cooling System Cleaning: Kamehla hloekisa tsamaiso ea ho pholisa ho tlosa lithōle le ho boloka bohloeki ba eona.

4.Magazine ea Tool le Tlhokomelo ea ho Fetola Lisebelisoa

Ho Hloekisa Makasine ea Lisebelisoa: Hloekisa makasine ea lisebelisoa khafetsa ho netefatsa hore lisebelisoa li bolokoa ka makhethe le ho qoba ho thulana.

Tlhahlobo ea Tool Changer: Kamehla hlahloba mochine o fetolang lisebelisoa ho netefatsa hore o sebetsa ka mokhoa o tloaelehileng.

5.Lathe Precision Maintenance

Tlhahlobo ea Boemo ba Boemo: Kamehla hlahloba boemo ba lathe ho netefatsa hore e nepahetse.

Mechanical Precision Calibration: Kamehla lekanya ho nepahala ha mochini ho boloka tšebetso ea lathe e nepahetse.

Ho Etsa Leano la Tlhokomelo

Ho netefatsa ts'ebetso e tloaelehileng le nako ea bophelo eamochini oa CNC oa li-spindle tse peli, lik'hamphani li lokela ho etsa moralo o nepahetseng oa tlhokomelo ea saense. Leano lena le tlameha ho kenyelletsa:

Cycle ea Tlhokomelo: Theha kemiso ea kamehla ea tlhokomelo e ipapisitseng le ts'ebeliso ea lisebelisoa le likhothaletso tsa moetsi.

Litaba tsa Tlhokomelo: Hlalosa ka ho hlaka se fuperoeng ke nako e 'ngoe le e 'ngoe ea tlhokomelo, joalo ka ho hloekisa, ho tlotsa le ho hlahloba.

Koetliso ea Basebetsi ba Tlhokomelo: Fana ka koetliso e hlokahalang ho basebetsi ba tlhokomelo ho netefatsa hore ba ka etsa mesebetsi ka nepo.

Litlaleho tsa Tlhokomelo: Boloka litlaleho tse qaqileng tsa tlhokomelo ho latela boemo ba thepa le nalane ea eona.

Ka ho kenya ts'ebetsong moralo oa tlhokomelo ka tieo, lik'hamphani li ka ntlafatsa ts'ebetso le botsitso ba li-lathe tsa CNC tse peli-spindle, ho fana ka tšehetso e matla bakeng sa tlhahiso le nts'etsopele.

Ka kakaretso, tlhokomelo ea letsatsi le letsatsi ea li-spindle tse peliCNC lathee bohlokoa bakeng sa ho netefatsa ts'ebetso e tloaelehileng, ho lelefatsa nako ea bophelo, ho ntlafatsa ts'ebetso e nepahetseng, le ho matlafatsa botsitso. Likhamphani li lokela ho etelletsa pele mosebetsi oa ho lokisa, ho etsa moralo o nepahetseng oa tlhokomelo, le ho o phethahatsa ka tieo ho tsoela pele ho ntlafatsa katleho ea tlhahiso le boleng ba sehlahisoa.

Nako ea poso: Apr-02-2025