TheOturnCenter-Drive Latheke sesebelisoa sa tlhahiso se sebetsang hantle, se nepahetseng hantle, le se tsoetseng pele, se nang le mahlale a mangata a etellang pele malapeng. Likarolo li ka tlamelloa hanngoe ho tlatsa selikalikoe se ka ntle, sefahleho sa ho qetela, le lesoba le ka hare la lipheletsong tse peli tsa workpiece ka nako e le 'ngoe,' me likarolo li ka thijoa ka makhetlo a mabeli Ha li bapisoa le mokhoa oa setso oa ho sebetsa ha U-turn. -drive lathe e na le ts'ebetso e phahameng ea tlhahiso le ho nepahala ho holimo ha coaxial ea likarolo tse sebetsitsoeng. Hajoale, k'hamphani ea rona e hlahisitse lintlha tse fetang leshome tsa lihlahisoa tse nang le lihlooho tse peli 'me e se e tsebisitsoe' marakeng. Clamping Bophara bo tloha ho φ5mm-φ250mm, 'me bolelele ba ho sebetsa bo tloha ho 140mm-2500mm.

Mofuta o mong oa sehlahisoa ke aHabeli Spindle CNC Lathe, e loketseng ho fetola disc kapa likarolo tse khutšoanyane tsa shaft tse nang le bophara ba Φ200mm le bolelele ba lesoba le ka hare ho 120mm. Likarolo li kenngoa ka bo eona ka li-spindle tse peli ho phethela tšebetso eohle ea tatellano e 'meli. Mefuta e 'meli e ka holimo ea li-lathe tsa CNC e ka ba le lisebelisoa tsa ho kenya le ho laolla le ho boloka lisebelisoa ho phethahatsa tlhahiso e ikemetseng ka ho feletseng.

Bohareng ba koloiCNC latheke lathe ea CNC e sa tloaelehang, e leng ea lisebelisoa tse khethehileng tsa mochini. Moreki o amohela sengoathoana sa lisebelisoa, o sebelisana le moralo oa kopo ea tekheniki, o laola litšenyehelo ka nepo, o khotsofatsa kopo ea ts'ebetso ea moreki hantle. Ha ho bapisoa le machining a tsela e le 'ngoe ea lesela la setso la CNC, lathe ea bohareng e sebelisa hlooho ho etsa machining a mabeli a mosebetsi, 'me katleho ea machining ea theory e mena habeli ea lathe ea setso. Haholo-holo bakeng sa li-workpieces tsa mofuta oa disk kapa li-workpieces tsa mofuta oa shaft-processing tse hlokang coaxiality e batlang e le holimo 'me ha ho bonolo ho tlamelloa habeli,bohareng ba koloi CNC lathee batla e le eona feela e sebetsang hantle mme e ka netefatsa litlhoko tsa coaxiality le ho nepahala. mochini.

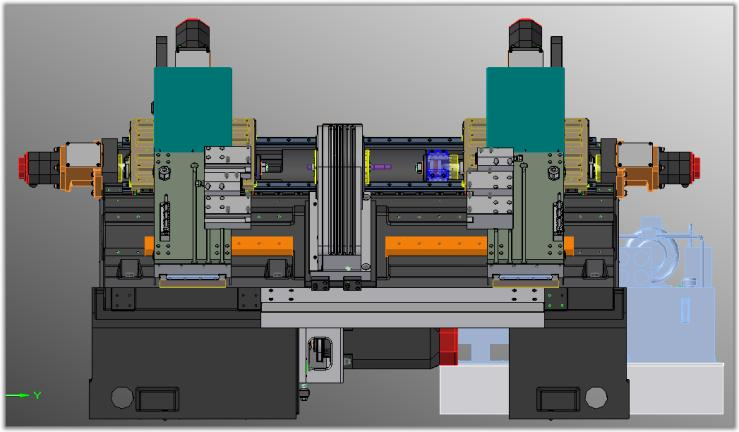

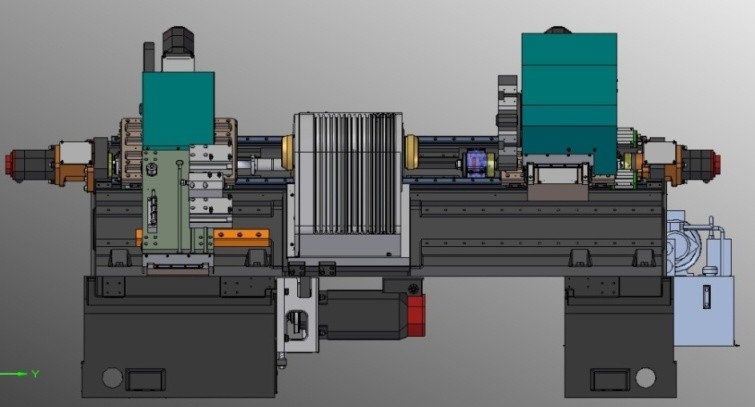

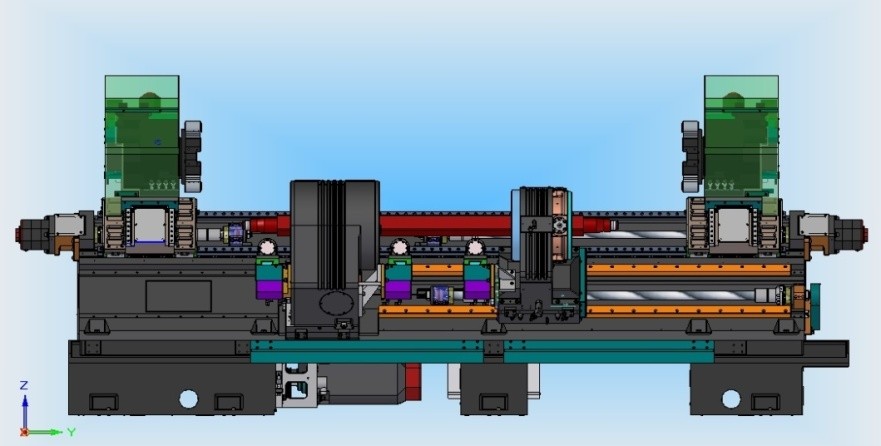

The hlooho e 'meli ea CNC lathe haholo-holo e na le likarolo tse latelang: tafole e thellang ka ho le letšehali le ka ho le letona, kariki e kholo ea ka ho le letšehali le ka ho le letona, li-screws tsa bolo ea longitudinal ka ho le letšehali le ka ho le letona, li-motor tsa servo tsa longitudinal, lisebelisoa tsa motlakase le tsamaiso ea lipalo. Pakeng tsa litafole tse thellang ka ho le letšehali le ka ho le letona, ho na le setulo sa spindle se hokahaneng hantle le sona. Setulo sa spindle se na le sekoti se sekoti, lebokose la phetiso le motlakase oa ho fetola maqhubu. Hollow main shaft, transmission box le frequency conversion motor. Ka ho le letšehali le ka ho le letona likariki tse kholo li na le likariki tse tšekaletseng ka ho le letšehali le ka ho le letona. Likariki tse bohareng tse ka ho le letšehali le ka ho le letona li na le li-screws tsa bolo tse ka ho le letšehali le tse ka ho le letona le li-motor tsa servo tse tšekaletseng ka ho le letšehali le ka ho le letona.

Hlooho e le 'ngoe/habeli

Poso ea sesebelisoa: rotary/row tool/power

Sesebelisoa sa Hydraulic: mofuta oa collet, mofuta oa claw

Multi-configuration/multi-function bakeng sa kgetho

Melemo ea Center-drive lathe

1. Ho tsepamisa mohopolo oa lits'ebetso, ho fokotsa palo ea linako tsa ho koala li-workpiece.

2. Hang ha clamping, mahlakore ka bobeli a tla sebetsoa ka nako e le 'ngoe.

3. Khutsufatsa mokhoa oa tlhahiso.

4. E na le lisebelisoa tsa ho kenya le ho laolla le lisebelisoa tsa polokelo ho hlokomela tlhahiso e ikemetseng ka botlalo.

5. Sebaka sa mosebetsi se koaletsoe sebakeng se bohareng, clamping e ka tšeptjoa, 'me torque e hlokahalang ho fetisetsa mochine oa mochine o lekane,' me moeli o moholo o ka fetoloa.

Kenyelletso ea mochini:

Joalo ka China e ntle ka ho fetisisaCenter Drive Lathe Machine feme, re amohela sebopeho sa bethe se sekametseng sa 45 °, se nang le boits'oaro bo botle le ho tlosa li-chip tse bonolo. The headstock e nang le intermediate drive clamping function e hlophisitsoe bohareng ba bethe, 'me lisebelisoa tse peli tsa lisebelisoa li hlophisitsoe ka mahlakoreng ka bobeli a hlooho ea hlooho. Tataiso ea ho roala e amohetsoe, 'me shaft e' ngoe le e 'ngoe ea servo feed e nka sekoti sa bolo e sa bueng holimo,' me khokahano ea elastic e hokahane ka kotloloho, 'me lerata le tlase, ho nepahala ha maemo le ho nepahala ha maemo ho holimo.

E na le tsamaiso ea li-channel tse peli, lisebelisoa tse peli tse phomolang li ka amahanngoa le spindle ka nako e le 'ngoe kapa li arohane ho phethahatsa ts'ebetso ea nako e le' ngoe kapa e latellanang ea lipheletsong tse peli tsa karolo. Sesebelisoa sa mochini se nka moralo oa modular mme se ka ba le sebopeho se fapaneng, tlhophiso, le metsoako ea ts'ebetso ho latela litlhoko tsa hau. Ho na le likhetho tse peli bakeng sa sets'oants'o sa thipa, mofuta oa thipa ea mola kapa mofuta oa turret. Sets'oants'o sa thipa se melang se na le lihlopha tse tharo tsa liporo tsa tataiso ka bolelele, 'me lithipa tse 'ne li ka kenngoa holimo le tlase.

Spindle e le 'ngoe, sesebelisoa sa sehlopha sa litlokotsebe sa turret, sebopeho sa turret se nepahetseng

Li-spindle tse le mong, ba tšoereng lisebelisoa ka ho le letšehali le ka ho le letona ke sebopeho sa lisebelisoa tsa sehlopha sa litlokotsebe

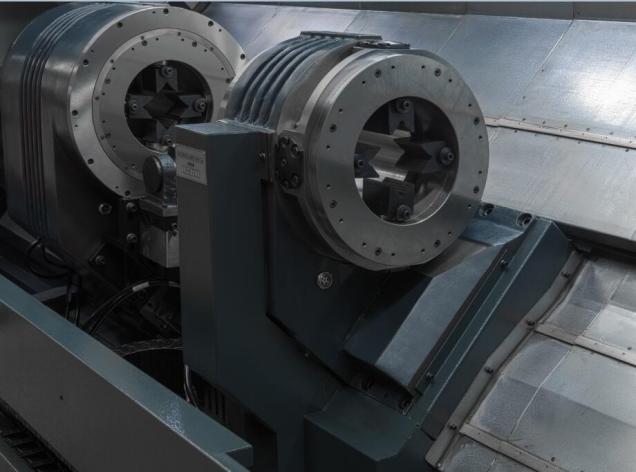

Ho ea ka boemo bo se nang letho, boholo, le sebōpeho sa karolo, mokhoa oa ho koala, bolelele ba axial, bophara ba lesoba le bophara ba lebokose la spindle le nang le sesebelisoa sa mochine o mong le o mong o ka khethoang ka thoko. Li-clamping tse mahareng le lipheletsong tse peli lia koala. The collet-type headstock, the middle clamping, and two-end clamping jaw-type headstock, ho na le extendable headstock, ultra-short headstock, high clamping accuracy headstock, le clamping accuracy ka fihla 0.005mm. Bolelele ba karolo bo ka hlomelloa ka hlooho e le 'ngoe kapa lihlooho tse peli.Sehlooho sa li-medium-drive lathe se tsitsitse,' me hlooho e ka tlaase e ka tsamaisoa ka axially (ka letsoho kapa servo-movable). E ka boela ea sebelisoa bakeng sa tse peli Lebokose la spindle le tlamisoa ho phethela ts'ebetso ea likarolo tse telele, hape le ka sebelisoa ho sebelisa feela lebokoso la spindle ho koala ho phethela tšebetso ea likarolo tse khutšoane. Lebokose la spindle le kopanya likarolo tse tharo tsa mochini oa spindle, clamping, le silindara ea oli. Sebopeho se kopane 'me mosebetsi oa tšepahala.

Bolelele bo phahameng ba machining ba hlooho ea hlooho e habeli ke 2500mm, 'me bophara bo boholo ba lesoba la hlooho bo ka fihla ho Φ370mm. Lisebelisoa tsa li-clamping kaofela li khannoa ka metsi, 'me matla a ho koala a ka finyella litlhoko tsa torque e phahameng ka ho fetisisa. Ho na le likhetho tse ngata bakeng sa chuck haeba bophara ba karolo bo hlalositsoe Ho na le tse ngata, tse amohelang sebopeho sa ho kenya claw ea ho lokisa ka har'a chuck, e bonolo haholo ebile e potlakile ho e nkela sebaka.

TheCenter Drive CNC Lathee ka boela ea hlomelloa ka lisebelisoa tsa ho jarolla le ho laolla le lisebelisoa tsa polokelo ho hlokomela ts'ebetso ea othomathike ka botlalo.

Lathe ea bohareng ba koloi e koetsoe ka ho feletseng 'me e sirelelitsoe, e na le lubrication e itekanetseng le lisebelisoa tsa ho tlosa li-chip, tse nang le ts'ebetso e ntle ea tšireletso, ts'ebetso e bonolo le tlhokomelo e bonolo.

Likarolo tse loketseng bakeng sa ho lokisa lathe ea bohareng:

1. Likarolo tsa likoloi:

Gearbox input shaft, gearbox output shaft, welded axle, steering rod, half shaft, shaft tube, shock absorber piston tube, trailer axle, torsion bar.

Shaft ea ho kenya Gearbox

Gearbox output shaft

molamu oa ho tsamaisa

Half shaft

Monyetla o tshosang

Shaft tube

2. Likarolo tse ling tsa sehlahisoa sa mochini:

Mochini oa motlakase, rolara ea mochini o ohlang, hlobo ea botlolo, motsoako oa peipi ea ho cheka oli, moqomo oa rotor ea pompo ea metsi, moqomo oa mochini oa khatiso.

rolara mochini o ohiang le Motor shaft

Motsoako oa peipi ea ho phunya oli le pompo ea metsi ea rotor shaft

Khalase hlobo Le Moropa oa mochini oa khatiso

Liindasteri tse kholo moo ho sebelisoang li-lathes tse mahareng:

1. Indasteri ea likoloi:

Ho lokisa li-gear shafts tsa li-gearbox tsa koloi

Ho sebetsa li-axle tsa k'haravene ea koloi

Ho sebetsa hub axle tube ea koloi

Ho sebetsa axle tube ea koloi

Ho etsa mochini oa letsoho la koloi

E sebetsana le shaft ea axle ea koloi

2. Indasteri ea mochini oa masela:

Ho sebetsana le rolara ea mochini o ohla

3. Indasteri ea hlobo:

Ho sebetsa hlobo ea botlolo ea khalase

4. Indasteri ea likoloi:

Mochini oa mochini oa mochini

5. Indasteri ea pompo ea metsi:

Ho sebetsa shaft ea rotor ea pompo ea metsi

6. Indasteri ea mechine ea khatiso:

Ho sebetsa li-cylinders le lipoleiti tsa khatiso ea khatiso

Sehlopha sa lihlahisoa tsa li-lathes tsa bohareng ba koloi:

Center Drive Lathe Bakeng sa Coupling,Center Drive Lathe Bakeng sa ho Tšehetsa Roller,Center Drive Lathe For Thin-walled tube,Center Drive Lathe bakeng sa hlobo ea khalase,Center Drive lathe bakeng sa axle.

Ntlha e le 'ngoe eamafahla a spindleCNC lathee bohlokoa haholo. Sesebelisoa sa workpiece se sebelisetsoa ho lokisa workpiece ka nepo holim'a spindle nakong ea ts'ebetso ea machining. Matla a hlahisoang nakong ea ts'ebetso ea mochine le ntho e tsitsitseng e tlameha ho ba e tsitsitseng le e se nang likheo. Lisebelisoa tse nang le boleng bo tsitsitseng li amana haufi-ufi le moralo o matla oa tekheniki le bokhoni ba R&D. Tšebelisano e phethahetseng ea lienjiniere tsa rona tsa mechini, lienjineri tsa motlakase le lienjiniere tsa software li ka nkuoa e le sistimi e felletseng ea tšehetso ea tekheniki.

Baenjiniere ba sehlopha sa rona ba tla hlophisoa ho latela litlhoko tse ikhethang tsa bareki liindastering tse fapaneng. Ntle le ts'ebetso e phahameng ea lipheletsong ka bobeli ka nako e le 'ngoe ea lathe ea bohareng ba drive, e boetse e fokotsa haholo chelete e kenang ea moreki.

TheCNC hlooho e habeli latheke sesebelisoa se ikhethileng sa mochini, 'me ke mohlala oa bohlokoa haholo ha ho etsoa mela ea tlhahiso ea othomathike. Sehlopha sa CNC mafahla a spindle mochinie kopane. Ntlafatso, moralo le khetho ea lisebelisoa tsa mochini, lisebelisoa le lisebelisoa, tlhahlobo le tekanyo, lipalangoang tsa thepa, ts'ireletso le kalafo ea li-chips le pholiso kaofela li ntho e le 'ngoe. Lisebelisoa tsa mochini o khethehileng li hlahisoa mochining o le mong. Ho ea ka litlhoko tsa bareki, moralo o le mong, nts'etsopele e le 'ngoe, le tlhahiso e le' ngoe e hlokahalang ho netefatsa katleho ea nako e le 'ngoe.

Thetlhapi e habeli latheIndasteri ea likarolo tse sebetsang e thehile nts'etsopele ea indasteri Chaena, 'me e bapisoa le balekane ba kantle ho naha mabapi le tekanyo ea tlhahiso le lisebelisoa tsa hardware. Hammoho le ho hlaha ha likhoebo tse ngata tse ncha lilemong tsa morao tjena, likhoebo tsena li na le lisebelisoa tse tsoetseng pele tsa ts'ebetso le mehopolo e tsoetseng pele ea theknoloji lapeng le kantle ho naha, 'me esale li tsoela pele ho etsa lipatlisiso le ho nts'etsapele, hammoho le ntlafatso e tsoelang pele le likhatelopele tsa nts'etsopele ea mahlale a macha. mehlala, ho phehella tshebetso e phethahetseng le Boleng, maikutlo a nepahetseng haholoanyane 'marakeng oa machaba, e amoheloa le ho amoheloa ke bareki ba tsoang linaheng tse ling.

Nako ea poso: Sep-18-2021