Mochini o tloaelehileng oa latheke mofuta oa mochine oa lathe oa setso o sa laoleheng empa o etsoa ka letsoho. E na le mefuta e mengata ea ho itšeha 'me e khona ho sebetsana le masoba a ka hare, li-circles tse ka ntle, lifahleho tse qetellang, libaka tse tapered, chamfering, grooving, likhoele le libaka tse fapaneng tsa arc. Li-lathes tse tloaelehileng ke mofuta o sebelisoang haholo oa mechine ea lathe, e etsang karolo ea 65% ea palo eohle ea mochine oa lathe. Li bitsoa li-lathe tse tšekaletseng hobane li-spindle tsa tsona li behiloe ka tsela e tšekaletseng.

Mesebetsi:

1. Ho phethoha ha moqomo o ka ntle, ho phethoha ha khoune, ho phethoha ha bokaholimo bo kobehileng, ho phethoha ha lesoba le ka hare, ho phethoha ha sefahleho, ho checha le machining a mang;

2. Metric thread, inch thread, modular thread, pitch thread cutting;

3. Ho thunngoa le ho phethoha ha taper e telele;

4. Ho cheka, ho bora, ho phunya le ho phunya;

5. Ho thinya ha letsoho le letshehadi le ho phethola letsoho le letona;

6. Esita le ho sila le ho sila ka ho sila le ho khomarela ho sila.

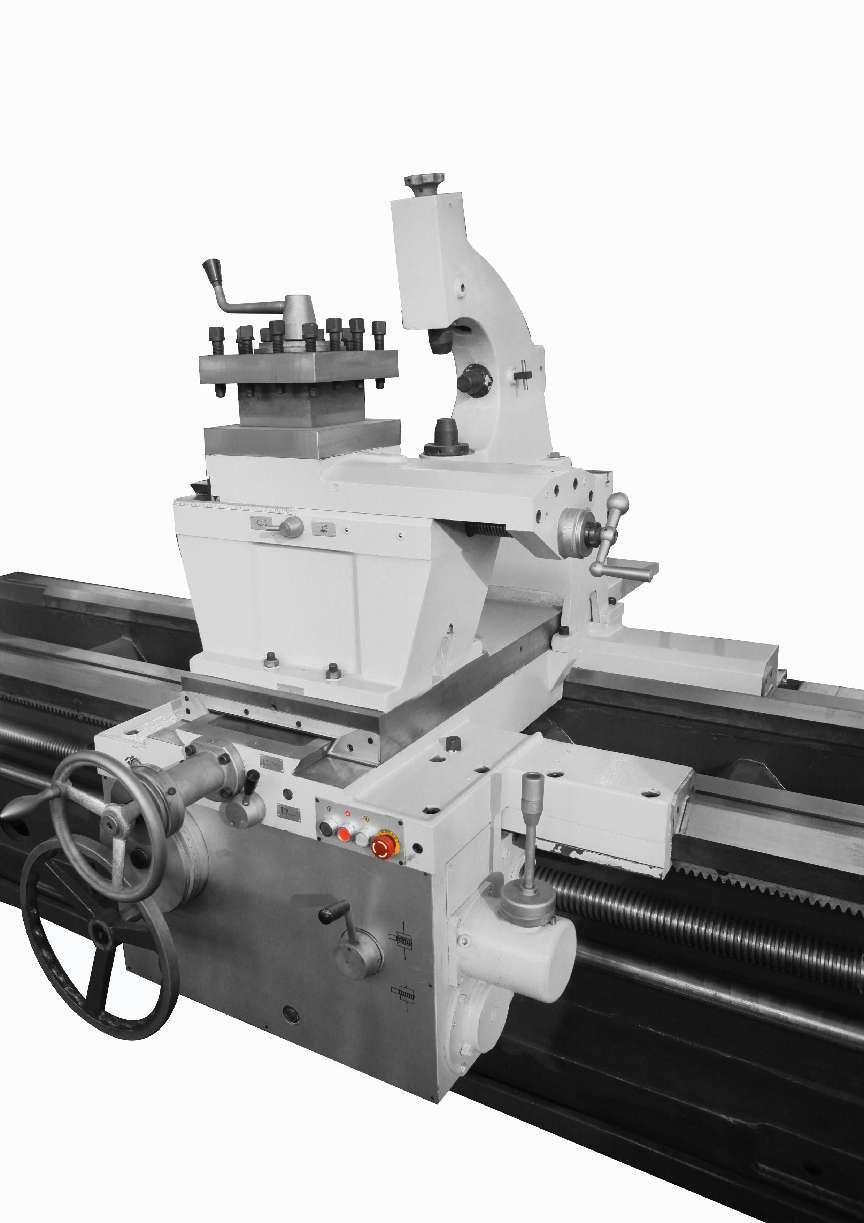

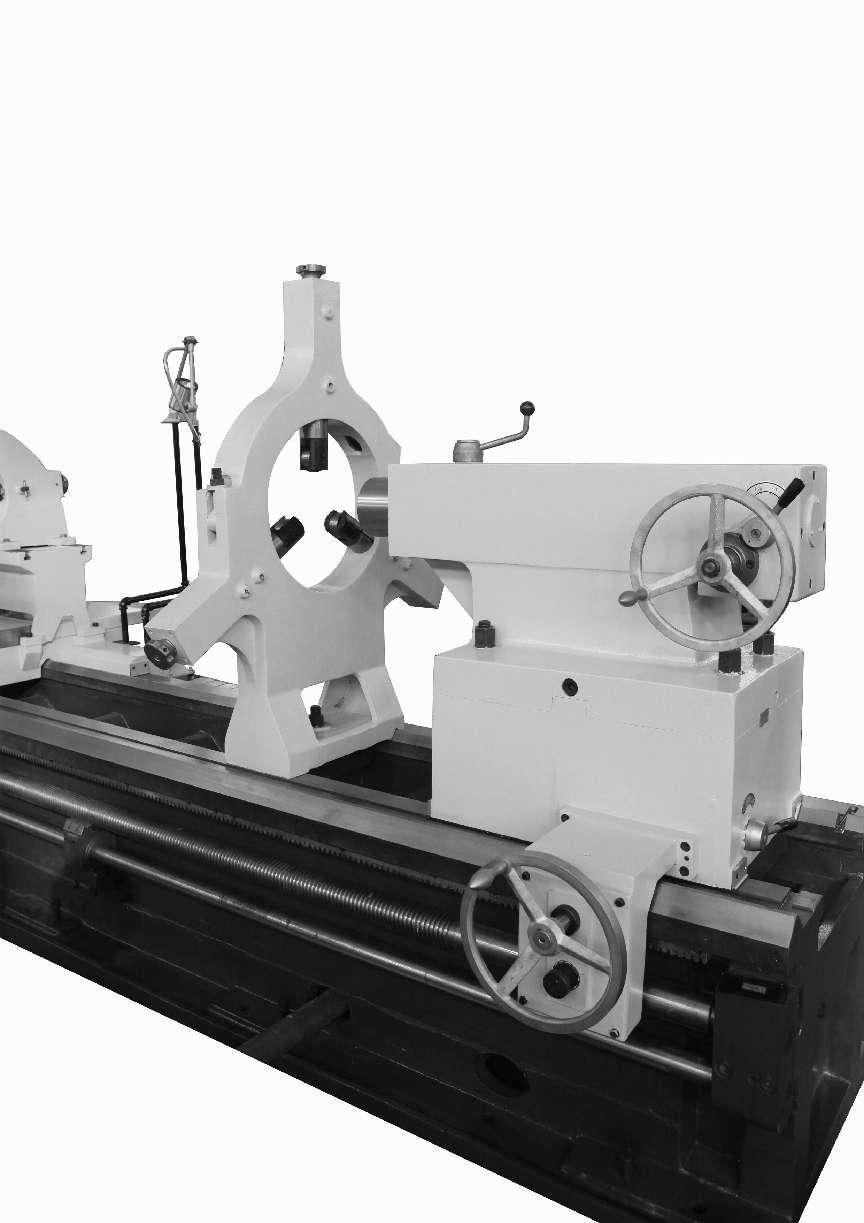

Likarolo tse kholo tsamechine e tloaelehileng: bethe, hlooho ea hlooho, lebokose la lijo, poso ea lisebelisoa, kariki, tailstock, le koloi.

Bethe: Likarolo tse kholo tsamochine oa latheli kenngoa holim'a bethe, e le hore li boloke boemo bo nepahetseng bo lekanyelitsoeng nakong ea mosebetsi.Kariki le tailstock li thella holim'a bethe e entsoeng hantle.

Hlooho ea hlooho: The headstock e kenngoa ka thata ho ea betheng 'me e tšoara mekhoa eohle, ho kenyelletsa le mefuta e sa tšoaneng le metsoako ea li-pulleys kapa li-gear.Mosebetsi oa eona o ka sehloohong ke ho fetisa motsamao oa ho potoloha ho tloha mochine o moholo ka letoto la mekhoa ea ho fetola lebelo e le hore sefate se seholo. e ka fumana lebelo le fapaneng le hlokahalang la ho potoloha ho ea pele le ho khutlela morao, 'me ka nako e ts'oanang, hlooho ea hlooho e arola karolo ea matla a ho fetisetsa motsamao ho lebokose la fepa.Headstock Medium spindle ke karolo ea bohlokoa ea lathe.Boreleli ba spindle. ho matha holim'a bere ho ama ka ho toba boleng ba ts'ebetso ea workpiece. Hang ha ho nepahala ha ho potoloha ha spindle ho fokotsehile, boleng ba tšebeliso easesebelisoa sa mochinie tla fokotseha.

Lebokose la lijo: Lebokose la phepelo le na le mochini oa phetoho ea lebelo bakeng sa motsamao oa ho fepa. Lokisa mochine oa ho fetola lebelo ho fumana chelete e hlokahalang ea phepelo kapa molumo, 'me u fetisetse motsamao ho sesebelisoa ka sekurufu se boreleli kapa sekurufu sa lead bakeng sa ho khaola. Ha u fetola libaka tse ling tsa workpiece, ho sebelisoa screw e boreleli feela ho e-na le screw lead.

Sets'oants'o sa lisebelisoa: Sets'oants'o sa lisebelisoa se entsoe ka likarolo tse 'maloa tsa lisebelisoa tsa lisebelisoa. Mosebetsi oa eona ke ho tiisa sesebelisoa le ho etsa hore sesebelisoa se tsamaee ka longitudinally, ka thōko kapa ka mokhoa oblique.

Mohatla: E le setsi se ka morao bakeng sa ts'ehetso ea boemo, e ka boela ea kenngoa ka lisebelisoa tsa ho lokisa likoti tse kang li-drill le li-reamer bakeng sa ho sebetsana le mekoti.

likarolo

Chuck ea mehlahare e meraro (bakeng sa lisebelisoa tsa cylindrical)

chuck ea mehlahare e mene (bakeng sa lisebelisoa tse sa tloaelehang)

sebopeho

Lisebelisoa tse tloaelehileng tsa mochineho ba le sebopeho se bonolo, ts'ebetso e bonolo, bophara bo boholo ba spindle, maoto a manyane, phetoho e kholo ea ts'ebetso, tlhokomelo e bonolo, e loketseng ts'ebetso e nyane ea batch le ts'ebetso e phahameng ea litšenyehelo.

Bethe e nka bethe ea bohlokoa e nang le rigidity e phahameng.Mochine o na le pompo e fapaneng ea oli. Seselaete, sets'oants'o sa lisebelisoa, le sale li ka tsamaea kapele. Sesebelisoa sena sa mochine se ka amohela tsamaiso ea GSK kapa SIEMENS ea boikhethelo, mokhoa oa ho laola lipalo oa FANUC le mekhoa e meng ea ho laola lipalo ho ea ka litlhoko tsa mosebedisi, tse ka etsang ho itšeha ka lebelo le phahameng, le matla le le tsitsitseng, ho nepahala ha machining le lenaneo le bonolo.

Thee tsepameng le e tshekaletsengfeed e nka AC servo motor, 'me karabo ea pulse encoder e sebelisoa e le karolo ea maikutlo. Lithaele tse otlolohileng le tse otlolohileng tsa tataiso ea motsamao li tlas'a ho thatafala ha ultrasonic le kalafo e ntle ea ho sila. Seporo sa tataiso ea bethe se kentsoe ka tepi e bonolo ea PTFE, 'me coefficient ea likhohlano e nyane.

Enjene e kholo e nka mokhoa o tsoakaneng oa taolo ea lebelo la taolo ea matla a khoheli le taolo ea voltage, e le ho etsa taolo ea lebelo la spindle ntle le mohato.

Mekhoa ea ts'ebetso

1. Tlhahlobo pele e qala

1.1 Eketsa mafura a loketseng ho latela chate ea ho tlotsa mochini.

1.2 Sheba lisebelisoa tsohle tsa motlakase, ho tšoara, likarolo tsa phetisetso, lisebelisoa tsa tšireletso le moeli li phethehile, li ka tšeptjoa ebile lia tenyetseha.

1.3 Gear e 'ngoe le e' ngoe e lokela ho ba boemong ba zero, 'me tsitsipano ea lebanta e lokela ho finyella litlhoko.

1.4 Ha e lumelloe ho boloka lintho tsa tšepe ka ho toba betheng, e le hore u se ke ua senya bethe.

1.5 Sebaka sa ho sebetsa se lokelang ho sebetsoa ha se na seretse le lehlabathe, se thibela seretse le lehlabathe hore li se ke tsa oela mochining le ho senya seporo sa tataiso.

1.6 Pele mosebetsi oa ho sebetsa o koaletsoe, ho lokela ho etsoa tlhahlobo ea koloi e se nang letho, 'me mosebetsi o ka kenngoa feela ka mor'a ho netefatsa hore ntho e' ngoe le e 'ngoe e tloaelehile.

2. Ts'ebetso ea ts'ebetso

2.1 Ka mor'a hore mochine oa mosebetsi o kenngoe, qala pompo ea oli e tlotsang pele ho etsa hore khatello ea oli e finyelle litlhoko tsa mochine pele u qala.

2.2 Ha u lokisa mochine oa lisebelisoa tsa phapanyetsano, ha u lokisa lebili le leketlileng, motlakase o tlameha ho khaoloa. Ka mor'a hore ho lokisoe, liboutu tsohle li tlameha ho tiisoa, wrench e lokela ho tlosoa ka nako, 'me sesebelisoa sa mosebetsi se lokela ho khaoloa bakeng sa ts'ebetso ea teko.

2.3 Ka mor'a ho kenya le ho laolla sesebediswa sa mosebetsi, sekontiri sa chuck le likarolo tse phaphametseng tsa workpiece li lokela ho tlosoa hang-hang.

2.4 The tailstock, crank handle, joalo-joalo ea mochine oa mochine o tla lokisoa ho ea libakeng tse loketseng ho ea ka litlhoko tsa ts'ebetso, 'me e tla tiisoa kapa e tlanngoe.

2.5 Lisebelisoa, lisebelisoa le lisebelisoa li tlameha ho kenngoa ka mokhoa o sireletsehileng. Sesebelisoa sa matla a phaphametseng se tlameha ho atolosa karolo e kenang ka har'a sesebelisoa pele se qala sesebelisoa sa mochini.

2.6 Ha u sebelisa sebaka sa phomolo sa bohareng kapa phomolo ea lisebelisoa, setsi se tlameha ho lokisoa hantle, 'me ho be le lubrication e ntle le libaka tse tšehetsang tsa ho kopana.

2.7 Ha o sebetsana le lisebelisoa tse telele, karolo e hlahelletseng ka mor'a sefate se seholo ha ea lokela ho ba nako e telele haholo.

2.8 Ha o fepa thipa, thipa e lokela ho atamela mosebetsi butle ho qoba ho thulana; lebelo la koloi le lokela ho lekana. Ha u fetola sesebelisoa, sesebelisoa le sesebelisoa se tlameha ho bolokoa hole.

2.9 Sesebelisoa sa ho itšeha se tlameha ho tiisoa, 'me bolelele ba katoloso ea sesebelisoa sa ho fetola hangata ha se makhetlo a 2,5 ho feta botenya ba sesebelisoa.

2.1.0 Ha ho etsoa likarolo tsa eccentric, ho tlameha ho ba le boima bo nepahetseng ho leka-lekanya bohareng ba matla a khoheli a chuck, 'me lebelo la koloi e lokela ho ba le loketseng.

2.1.1. Ho tlameha ho be le mehato ea ts'ireletso bakeng sa workpiece eo chuck ea eona e fetang fuselage.

2.1.2 Tokiso ea litlhophiso tsa lisebelisoa e tlameha ho tsamaea butle. Ha ntlha ea sesebelisoa e le 40-60 mm hole le karolo ea ts'ebetso ea workpiece, ho e-na le hoo, ho lokela ho sebelisoa lijo tsa matsoho kapa tse sebetsang, 'me lijo tse potlakileng ha lia lumelloa ho kenya letsoho ka ho toba.

2.1.3 Ha u bentša workpiece ka faele, sets'oants'o sa lisebelisoa se lokela ho khutlisetsoa sebakeng se sireletsehileng, 'me opereishene e shebane le chuck, ka letsoho le letona ka pele le letsoho le letšehali ka morao. Ho na le senotlolo holimo, 'me ho thibetsoe ho sebelisa faele ho sebetsana le workpiece ka lesoba la lisekoere.

2.1.4 Ha o bentša selikalikoe se ka ntle sa workpiece ka lesela la emery, mosebeletsi o lokela ho tšoara lipheletso tse peli tsa lesela la emery ka matsoho a mabeli ho li bentša ho ea ka boemo bo boletsoeng sehloohong se fetileng. Ho thibetsoe ho sebelisa menoana ea hau ho tšoara lesela la abrasive ho bentša lesoba le ka hare.

2.1.5 Nakong ea ho fepa ka thipa ka mokhoa o itekanetseng, sets'oants'o sa thipa se senyenyane se lokela ho lokisoa hore se be le botlaaseng ho thibela setsi ho ama chuck.

2.1.6 Ha u seha lisebelisoa kapa lisebelisoa tse kholo le tse boima, chelete e lekaneng ea ho sebetsa e lokela ho bolokoa.

3. Ts'ebetso ea ho paka

3.1 Khaola matla 'me u tlose workpiece.

3.2 Li-handle tsa karolo ka 'ngoe li theoleloa ho fihlela boemong ba zero, 'me lisebelisoa li baloa le ho hloekisoa.

3.3 Sheba boemo ba sesebelisoa se seng le se seng sa tšireletso.

4. Litlhokomelo nakong ea ts'ebetso

4.1 Ho thibetsoe ka thata hore batho bao e seng basebetsi ba sebelise mochini.

4.2 Ho thibetsoe ka thata ho ama sesebelisoa, karolo e potolohang ea mochine oa mochine kapa mochine o potolohang nakong ea ts'ebetso.

4.3 Ha e lumelloe ho sebelisa setopo sa tšohanyetso. Boemong ba tšohanyetso, ka mor'a ho sebelisa konopo ena ho emisa, e lokela ho hlahlojoa hape ho ea ka melao ea tsamaiso pele e qala mochine oa mochine.

4.4 Ha e lumelloe ho hata holim'a seporo sa tataiso, screw rod, polished rod, joalo-joalo ea lathe. Ntle le melaoana, ha e lumelloe ho sebetsa sephethephethe ka maoto ho e-na le matsoho.

4.5 Bakeng sa likarolo tse nang le li-blister, likoti tsa shrinkage kapa li-keyways leboteng le ka hare, li-scrapers tse tharo ha lia lumelloa ho khaola likoti tse ka hare.

4.6 Moea o hatelitsoeng kapa khatello ea metsi ea pneumatic back hydraulic chuck e tlameha ho fihla boleng bo boletsoeng pele e ka sebelisoa.

4.7 Ha u fetola li-workpieces tse tšesaane, ha bolelele ba mahlakore a mabeli a ka pele a hlooho ea bethe bo feta ka makhetlo a 4 bophara, setsi se lokela ho sebelisoa ho ea ka melao ea tsamaiso. Setsi sa phomolo kapa serethe se phomola. Balebeli le matšoao a lemosang ba lokela ho ekeletsoa ha ba hlahella ka mor'a hlooho ea bethe.

4.8 Ha seha litšepe tse brittle kapa seha se fafalitsoeng habonolo (ho kenyeletsoa le ho sila), li-baffles tse sireletsang li lokela ho eketsoa, 'me basebelisi ba lokela ho roala likhalase tse sireletsang.

tse ding

Ka botumo baMechine ea CNC,lisebelisoa tse ngata tsa boiketsetso li ntse li hlaha 'marakeng.Lathes ea setsoba na le melemo ea bona e ke keng ea nkeloa sebaka 'me e ntse e le mechini e hlokahalang bakeng sa lifeme tse ngata tse sebetsang.

1. Lisebelisoa tse tloaelehileng tsa mochineli theko e tlase

Theko ea theko eaLisebelisoa tsa CNCe theko e boima makhetlo a 'maloa ho feta ea e tloaelehileng lathe e nang le matla a tšoanang, 'me tlhokomelo ea morao-rao, ho lokisoa, ho tšehetsa lisebelisoa le litšenyehelo tse ling le tsona li phahame haholo ho feta eona.

2.Ho loketse haholoanyane bakeng sa machining a manyenyane

Ha li-workpieces tse nyane feela li hloka ho etsoa machining,basebetsi ba bangata ba nang le litsebo ba ka kenya karolo ka lisebelisoa tse tloaelehileng tsa mochine ka litšoantšo tsa likarolo.

3.Meputso e phahameng ea baetsi ba mananeo a CNC le litalenta tse fokolang

Baetsi ba mananeo ba CNC hangata ba hloka meputso e holimo, 'me ho na le mefuta e mengata ea litsamaiso tsa CNC. Ho hlakile hore ho thata le ho feta ho fumana opareitara e nang le tseboLisebelisoa tsa mochini oa CNCho feta mosebeletsi ea tloaelehileng oa lisebelisoa tsa mochini.

4.Mabapi le litšenyehelo tsa ho kenya khoebo

Ha ho nahanoa ka phetoho ea lichelete tsa likhoebo le tšebeliso e nepahetseng ea lisebelisoa, likhoebo tse ngata li boloka tlhahiso kamochine o tloaelehilenglisebelisoa.

Ka kakaretso, le hoja tlhahiso ea CNC e fetohile mokhoa o moholo ho nts'etsopele ea indasteri ea tlhahiso, lisebelisoa tse tloaelehileng tsa mochine li ntse li e-na le melemo ea tsona e ikhethang tabeng ea ho tsebahala ha lisebelisoa tse bohlale. Ka ntlafatso e tsoelang pele ea bohlale baLisebelisoa tsa mochini oa CNCnakong e tlang, lisebelisoa tsa mochine oa setso li ka nkeloa sebaka ka tekanyo e kholo, empa ho ke ke ha khoneha ho li felisa ka ho feletseng.

| MOHLALA | CW61(2)63E | CW61(2)80E | CW61(2)100E | CW61(2)120E | CWA61100 |

| MAKHONO | |||||

| Max.a tsubella betheng | 630 limilimithara | 800 limilimithara | 1000mm | 1200 limilimithara | 1000mm |

| Max.tsopa ka holim'a selaete | 350 limilimithara | 485 limilimithara | 685 limilimithara | 800 limilimithara | 620 limilimithara |

| Bolelele ba ho phethola | 750,1250,1750,2750,3750,4750,5750,7750,9750,11750mm | 1.5m 2m 3m 4m 5m 6m 8m 10m 12m | |||

| Max.feela ka holim'a lekhalo | 830 limilimithara | 1000mm | 1200 limilimithara | 1400 limilimithara | 780 limilimithara |

| Bolelele bo sebetsang ba lekhalo | 230m | 8T | |||

| Bophara ba bethe | 550 limilimithara | ||||

| SEHLOHO-THOE | Φ130 limilimithara | ||||

| Sekoti sa spindle | 105mm KAPA 130mm (KGETHO YA CW6180E+) | Metric140# | |||

| Nko ya spindle | D-11 kapa C-11 | 3.15-315r/min kapa 2.5-250r/min | |||

| Spindle taper | Φ120mm taper1:20(Φ140, KGETHO YA CW6180+) | Tsoela pele 21mefuta,Phetoho12mefuta | |||

| Mabelo a spindle(Palo) | 14-750RPM(MEHATO E 18) | ||||

| GEAR BOX-LIKHOELE & LIFEPE | 44mefuta e ka bang 1-120 mm | ||||

| Melemo ea mefuta (mefuta) | 1-240mm(54 mefuta) | 31 mefuta 1/4-24 T/I | |||

| Li-inch thread rang (Mefuta) | 28-1 inch(36 mefuta) | 45mefuta 0.5-60 limilimithara | |||

| Mefuta e fapaneng ea likhoele (mefuta) | 0.5-60 DP(27 mefuta) | 38mefuta ea 1/2-56DP | |||

| Mefuta e fapaneng ea likhoele tsa diametral | 30-1 tpi(27 mefuta) | 56 mefuta 0.1-12mm | |||

| Mefuta e mengata ea lijo tsa nako e telele | 0.048-24.3mm/r (72 mefuta) | 56mefuta 0.05-6mm | |||

| Mefuta e fapaneng ea lijo (mefuta) | 0.024-12.15mm/r (72 mefuta) | 3400mm/min,1700mm/min | |||

| Phepelo e potlakileng:Bolelele./Sefapano | 4/2m/min | ||||

| Boholo ba leadscrew: Diameter/Pitch | T48mm/12mm KAPA T55mm/12mm(bakeng sa 5M+) | 48mm | |||

| KAROLO | 45 * 45 limilimithara | ||||

| Ho tsamaea ka li-slide | 350 limilimithara | 420 limilimithara | 520 limilimithara | ||

| Leeto la phomolo le kopaneng | 200mm | 650 limilimithara | |||

| Boholo ba shank ea lisebelisoa | 32 * 32 limilimithara | 280 limilimithara | |||

| TAILSTOCK | |||||

| Bophara ba spindle | 100mm | 120 limilimithara | Φ160 limilimithara | ||

| Spindle taper | MORSE #6 | Metric 80# | |||

| Ho tsamaea ka spindle | 240 limilimithara | 300 limilimithara | |||

| MOTSAMAI | |||||

| Enjene ea koloi e ka sehloohong | 11kw | 22kw | |||

| Enjene ea pompo e pholileng | 0.09kw | 0.15kw | |||

| Enjene ea phepelo e potlakileng | 1.1kw | 1.5kw | |||

Nako ea poso: Apr-14-2022