5-Axis Vertical Machining Center Ka Mosebetsi oa ho Fetola

Setsi sa Machining sa Axis tse hlano

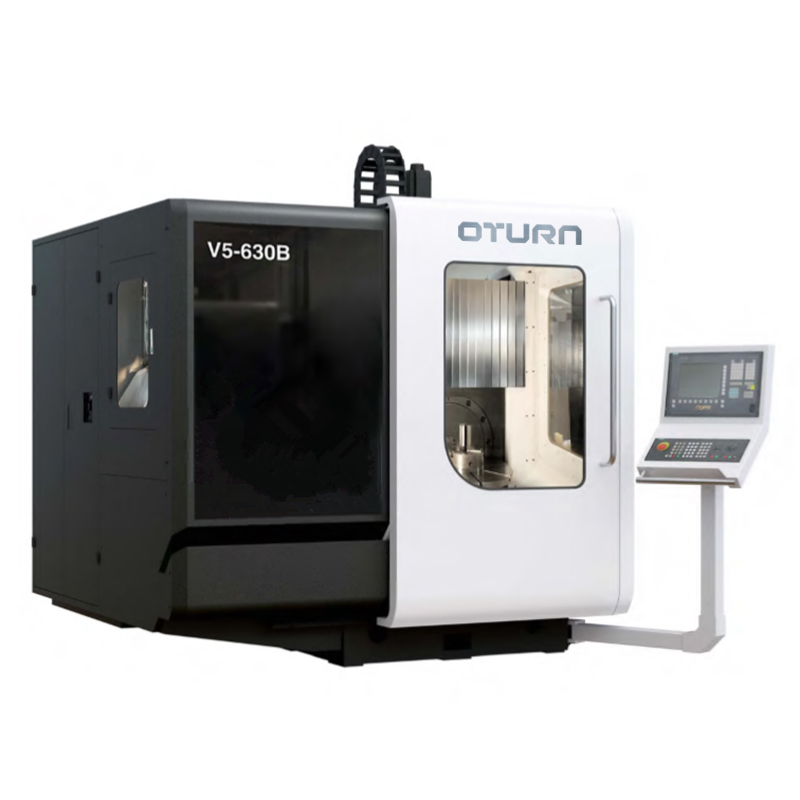

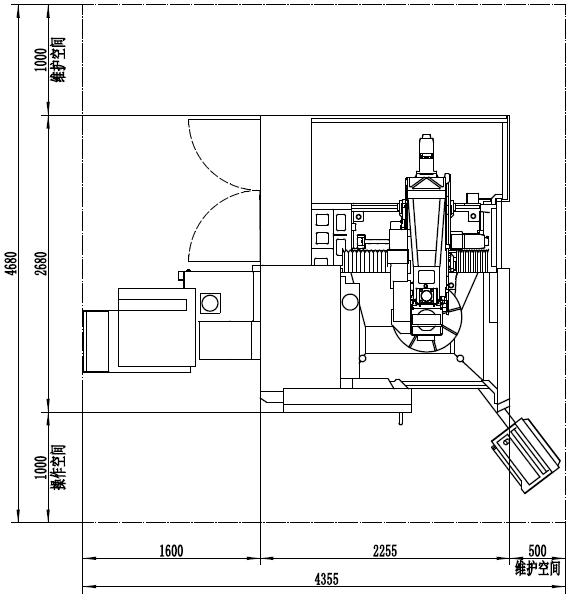

Setsi sa machining sa V5-630B sa li-axis tse hlano se nka sebopeho se tsitsitseng se bōpehileng joaloka C, kholomo e behiloe betheng, poleiti ea li-slide e tsamaea ka thōko ho kholomo (X direction), setulo sa slide se tsamaea ka nako e telele (Y directional), le hlooho ea hlooho e tsamaea e theohile haufi le setulo sa li-slide ( Z direction). Tafole ea ts'ebetso e nka sebopeho sa cradle sa letsoho le le leng le iketselitseng, 'me matšoao a fapaneng a ts'ebetso a fihlile maemong a holimo a machabeng.

Molaoli oa CNC: Siemens 840D

Sebopeho sa mochini:

Mokhoa oa ho fepa

Lilepe tsa X, Y, Z li sebelisa ho tiea ho hoholo, litataiso tsa linear tse nepahetseng haholo le likurufu tsa bolo tse sebetsang hantle haholo, tse nang le khohlano e tlase e matla le e tsitsitseng, kutlo e phahameng, ho thothomela ka lebelo le tlase, ntle le ho thella ka lebelo le holimo. ho nepahala ha maemo, le ts'ebetso e ntle haholo ea servo drive.

X, Y, Z axis servo motors li hokahane ka kotloloho le li-screws tsa bolo tse nepahetseng haholo ka ho kopanya, ho fokotsa likhokahano tse mahareng, ho hlokomela phetisetso e se nang lekhalo, phepelo e feto-fetohang, boemo bo nepahetseng, le ho nepahala ha phetiso e phahameng.

Enjene ea servo ea Z-axis e na le ts'ebetso ea brake. Tabeng ea ho felloa ke matla, e khona ho tšoara brake ka bo eona ho tšoara shaft ea motor ka thata hore e se ke ea potoloha, e leng se phethang karolo ea tšireletso.

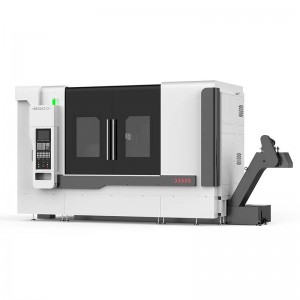

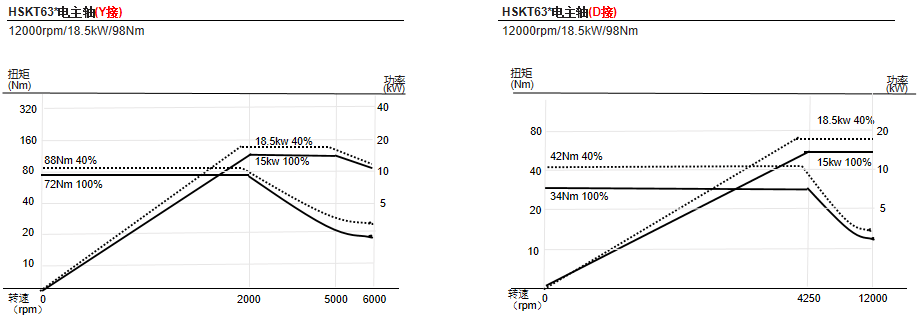

Motlakase oa spindle

Spindle e tsamaeang ka enjene e nka HSKT63 spindle e itlhommeng pele e nang le poleiti ea meno e hahelletsoeng kahare, e ka hlokomelang ts'ebetso e kopaneng ea ho bilika le ho sila. Qetello e na le motsoako oa lesale la spray ho pholisa sesebelisoa. Taolo ea lebelo e se nang mohato, e kentsoeng ka mokhoa o nepahetseng ka ho fetesisa, e ka khona ho emisa ka tsela e nepahetseng le ho tlanya ka thata.

Turntable

The self-developed direct-drive cradle turntable e na le encoder ea boemo bo holimo e nepahetseng haholo 'me e pholile ka metsi a pholileng ka mocheso o sa khaotseng. E na le melemo ea ho tiea ho hoholo, ho nepahala ho phahameng, le karabelo e matla e phahameng. Tafole ea ho sebetsa e nka 8-14mm radial T-slots, mojaro o moholo ke 500kg (e rapameng), 300kg (e otlolohileng), mme bophara bo boholo ba workpiece ke¢650.

Makasine ea lisebelisoa

Makasine ea sesebelisoa e amohela makasine ea mofuta oa HSKA63 manipulator disc, e ka amohelang 24.lisebelisoa.

Sistimi e koetsoeng ka botlalo ea loopm

X, Y, Z lilepe tse melang li na le sekala sa Renishaw sa boleng bo felletseng; Litafole tsa rotary tsa B le C li na le li-encoder tsa HEIDENHAIN RCN2000 letoto la boleng bo felletseng ho fumana maikutlo a felletseng a lilepe tse 5,guaranteed phahameng ho nepahala le phahameng ho nepahala ho boloka.

Mohatsela le tsamaiso ea moea

E na le pompo e kholo ea pholiso ea phallo le tanka ea metsi ho fana ka pholiso e lekaneng bakeng sa lisebelisoa le lisebelisoa. Sefahleho sa hlooho sa hlooho se na le li-nozzles tse pholileng, tse laoloang ke M code kapa control panel.

E na le mochine o pholileng oa metsi bakeng sa ho phomola mocheso o sa khaotseng, ho etsa bonnete ba hore spindle ea motlakase le turntable ea drive e tobileng li maemong a matle a ho sebetsa 'me li ka sebetsa ka katleho nako e telele.

Sistimi ea moea e sebelisa likarolo tsa moea ho sefa, 'me e hlokomela mesebetsi ea ho hloekisa le ho phethola lesoba le theiping la seluloana, tšireletso e tiisang moea ea seluloana, ho phethola sets'oants'o sa makasine ea sesebelisoa, le ho butsoela rula ea grating.

Sistimi e bohareng ea lubrication

Boloko ba selaete sa seporo sa tataiso le nate ea screw screw kaofela li tlositsoe ka mafura a tšesaane, 'me lubrication e fanoa khafetsa le ka bongata ho netefatsa bonnete le botsitso ba screw ea bolo le seporo sa tataiso.

Sistimi ea ho tlotsa moea ka oli

Seluloana sa motlakase se na le sesebelisoa sa ho tlotsa oli le khase se tsoang kantle ho naha, se khonang ho tlotsa le ho pholisa seluloana. Sensor e ka fana ka alamo e sa tloaelehang ea lubrication, e ka netefatsang hore spindle e ka sebetsa ka mokhoa o tsitsitseng ka lebelo le phahameng nako e telele.

Sistimi ea ho lekanya lisebelisoa tsa mosebetsi

Themochinie na le Renishaw OMP40 probe ea optical, e sebelisoang mmoho le moamoheli oa OMI-2, e hanyetsanang ka matla le tšitiso ea leseli, ts'usumetso ea bohata le tšusumetso, 'me tekanyo ea ho pheta-pheta ka tsela e le 'ngoe e ka tlase ho kapa e lekana le 1um (480mm/min) lebelo, ho sebelisa nale ea tekanyo ea 50mm), mocheso o sebetsang o sebetsang ke 5°C ho isa ho 55°C.

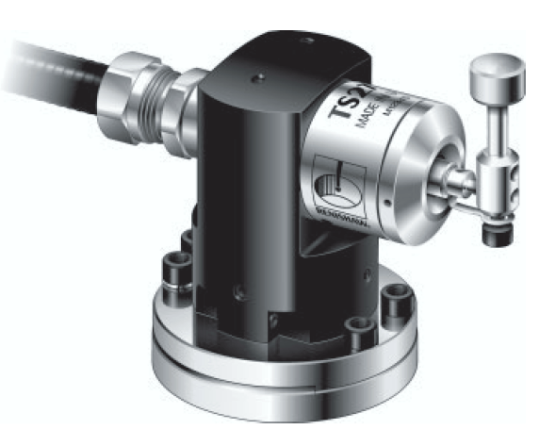

Sistimi ea ho lekanya lisebelisoa

Mochini o na le sistimi ea ho lekanya lisebelisoa tsa Renishaw's TS27R, e nolofalletsang ho lemoha lisebelisoa tse fapaneng le ho lekanya ka potlako bolelele ba sesebelisoa le bophara.

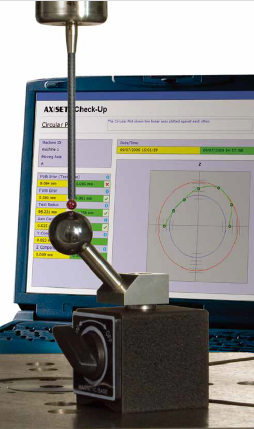

Mosebetsi oa ho lekanya ho nepahala ha li-axis tse hlano

Mochini o na le lisebelisoa tsa Renishaw's AxiSet Check-Up Rotary Axis Line Checker, tse kopantsoeng le sistimi ea ho lekanya lisebelisoa tsa OMP40, tse nolofalletsang.mochinibasebelisi ho lekola boemo ba lilepe tsa rotary kapele le ka nepo le ho tseba mathata a bakoang ke liphetoho tsa mocheso le mongobo,mochinilikhohlano kapa mathata a ho felloa ke matla, a ka khona ho lokisa kapele le ho fumana licheke tsa ts'ebetso, ho lekola le ho beha leihlo hore na ho rarahane hakaemochinis fetoha ha nako e ntse e ea.

Tšireletso ea mochine

Mochini o nka sekoaelo sa ts'ireletso se lumellanang le litekanyetso tsa polokeho ho thibela ho phatloha ha pholileng le li-chips, ho netefatsa ts'ebetso e bolokehileng le ponahalo e ntle. Tsela ea X ea mochine e na le sekoahelo se sirelelitsoeng se sirelelitsoeng, se ka sireletsang seporo sa tataiso ka katleho le sekoti sa bolo.

Maemo a ho sebetsa ka mochini

(1) Phepelo ea matla: 380V±10% 50HZ±1HZ ea mekhahlelo e meraro ea motlakase

(2) Mocheso oa tikoloho: 5℃-40℃

(3) Mocheso o motle ka ho fetisisa: 22℃±2℃

(4) Mongobo o amanang: 20-75%

(5) Khatello ea mohloli oa moea: 6±1 bar

(6) Phallo ea mohloli oa moea: 500 L / min

Tlhaloso e ka Sehloohong

| Ntho | Yuniti | Tlhaloso | |

| Tafole ea mosebetsi | Wbophara ba orktable | mm | φ630 |

| Boholo bo ka holimo bo otlolohileng | kg | 500 | |

| Boholo bo otlolohileng | kg | 300 | |

| T-slot | mm | 8x14 | |

| Ho sebetsa mefuta-futa | Sebaka pakeng tsa sefahleho sa spindle end le worktable end face(Max) | mm | 550 |

| Sebaka pakeng tsa sefahleho sa spindle end le worktable end face(Min) | mm | 150 | |

| X axis | mm | 600 | |

| Y axis | mm | 450 | |

| Z axis | mm | 400 | |

| B axis | ° | -35°~+110° | |

| C axis | ° | 360° | |

| Spindle | Mokoti oa khoele | CTB | HSKA63 |

| Lebelo le lekantsoeng | rpm | 2000 | |

| Lebelo le phahameng | Nm | 12000 | |

| Torque e hlahisoang ke S1/S6 | Nm | 72/88 | |

| Matla a enjene ea spindle S1/S6 | kW | 15/18.5 | |

| Axis | X axis Lebelo la ho haola ka potlako | m/m | 36 |

| Y axis Lebelo la ho haola ka potlako | m/m | 36 | |

| Z axisLebelo la ho haola ka potlako | m/m | 36 | |

| B axis Max.lebelo | rpm | 80 | |

| C axisMax.lebelo | rpm | 800 | |

|

| Matla a enjene ea X/Y/Z axis | KW | 2.2 |

|

| B/C axis Motlakase oa motlakase | KW | 13.3/30 |

|

| B-axis E lekantsoe torque | Nm | 2540 |

|

| C-axis Rated torque | Nm | 400 |

| Makasine ea lisebelisoa | Mofuta |

| Mofuta oa disk |

| Mokhoa oa ho khetha lisebelisoa |

| Khetho ea lisebelisoa tse haufi tse peli | |

| Bokhoni | T | 24 | |

| Max.bolelele ba sesebelisoa | mm | 300 | |

| Max.boima ba sesebelisoa | kg | 8 | |

| Max.bophara ba disc ea sehahi(E tletse Sesebelisoa) | mm | φ80 | |

| Maximum cutter disc bophara (Sesebelisoa se se nang letho se haufi) | mm | φ150 | |

| Ho nepahala | Mekhoa ea ts'ebetsong |

| GB/T20957.4(ISO10791-4) |

| Ho nepahala ha boemo(X/Y/Z) | mm | 0.008 | |

| ho nepahala ha boemo(B/C) |

| 6"/6" | |

| Ho nepahala ha maemo ho pheta-phetoang(X/Y/Z) | mm | 0.006 | |

|

| Ho nepahala ha maemo ho pheta-phetoang(B/C) |

| 4"/4" |

| Boima ba 'mele | kg | 6500 | |

| Bokhoni | KVA | 45 | |

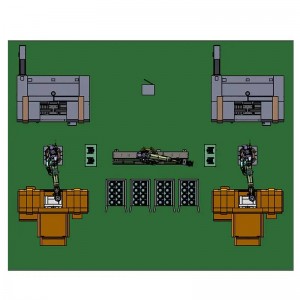

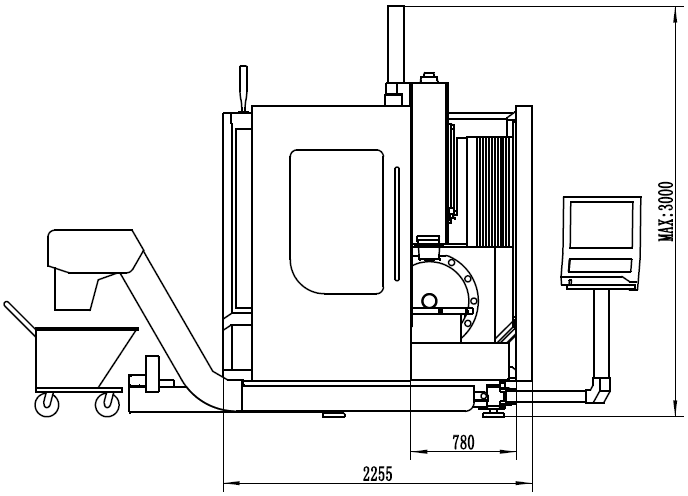

| Boholo ba mochini | mm | 4350×4000×3000 | |

Litlhophiso tse tloaelehileng

| 1. Likarolo tsa mantlha (ho kenyeletsoa bethe, kholomo, poleiti e thellang, setulo se thellang, lebokose la spindle) |

| 2. X, Y, Z tsamaiso ea phepelo ea li-axis tse tharo |

| 3. Letsoho le le leng la mofuta oa cradle-mofuta oa turntable BC630-4400T-42540T-800/800-50/80-RCNS |

| 4. Spindle ea motlakase HSKT63 |

| 5. Sistimi ea taolo ea motlakase (ho kenyeletsoa khabinete ea motlakase, module ea matla, module ea servo, PLC, phanele ea ts'ebetso, ponts'o, yuniti e ts'oaroang ka letsoho, mochini oa moea oa khabinete ea motlakase, joalo-joalo) |

| 6. Sisteme ea Hydraulic |

| 7. Sistimi ea moea |

| 8. Sistimi ea lubrication e bohareng |

| 9. Sistimi ea ho tlotsa moea ka oli |

| 10. Metsi a pholileng |

| 11. Chip conveyor, tanka ea metsi, pokello ea li-chip |

| 12. 'Musi oa grating |

| 13. Molebeli oa terene |

| 14. mochini ka kakaretso sekoahelo se sireletsang |

| 15. Mokhoa oa ho lekanya oa workpiece |

| 16. Sesebelisoa sa ho beha lisebelisoa |

| 17. Mosebetsi oa ho lekanya ho nepahala ha li-axis tse hlano |

| Lifaele tsa mochini setifikeiti Lenane la ho paka Sete e 1 ea buka ea mochini (mofuta oa elektroniki) data ea ho boloka mochini 1 set (U disk) Buka ea tlhahlobo ea alamo ea 840D 1 set (mofuta oa elektroniki) 840D Milling Operation Manual 1 (mofuta oa elektroniki) Buka ea motheo ea 840D karolo ea 1 (mofuta oa elektroniki)) |

Litlhophiso tse ka Sehloohong

| Lebitso | Brand | Ela hloko |

| X/Y/Z axis enjene le ho khanna | Siemens |

|

| Ketane ea matla | igus |

|

| Screw bearing | NSK/NACHI |

|

| Linear Guides | THK |

|

| Makasine ea lisebelisoa | Okada |

|

| Lubrication e bohareng | phula |

|

| Sekoti sa bolo | THK |

|

| Likarolo tsa Pneumatic | SMC |

|

| Motlakase oa khabinete ea moea ea moea | fofa mmoho |

|

| metsi a phodileng | fofa mmoho |

|

| 'musi oa grating | Renishaw |

|

| Sistimi ea ho lekanya lisebelisoa tsa mosebetsi | Renishaw |

|

| Sistimi ea ho lekanya lisebelisoa | Renishaw |

|

Lisebelisoa tse tloaelehileng

| Lebitso la sehlomathiso | Tlhaloso | Bongata |

| Mochine oa tšepe ea materase |

| 4 lihlopha |

| mehele | M20 | 2 likotoana |

| mehele | M30 | 2 likotoana |

| suspenders | 5T×2.85m | 1 |

| suspenders | 5T×2.8m | 1 |

| suspenders | 5T×3.75m | 1 |

| suspenders | 5T×3.8m | 1 |

| torx wrench e bulehileng | 22 | 1 |

| Allen senotlolo | 10 | 1 |

| Allen senotlolo | 12 | 1 |

| T-nut | M12 | 4 |

| Sets'oants'o sa spindle |

| 1 |

| Sebaka sa X-axis |

| 1 |

| Ho lokisa axis ea Y |

| 1 |

Ke leboha Tlhokomelo ea Hao!