Center Drive lathe Bakeng sa ho Tšehetsa Roller

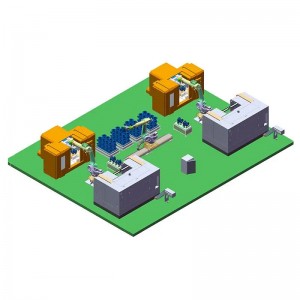

CNC lathe e habeli

Mochine oa CNC o nang le mahlakore a mabeli ke mochine o sebetsang hantle le o phahameng haholo. The workpiece clamped ka retelehela selikalikoe ka ntle, qetellong sefahleho le lesoba ka hare ka nako e tšoanang. Ts'ebetso ea tlhahiso e phahame ho feta mokhoa oa setso, 'me coaxiality le ho nepahala ha likarolo tse entsoeng li molemo.

Ho ea ka kopo ea moreki, ho kenya le ho laolla lisebelisoa tse thusang le lisebelisoa tsa ho jarolla le ho theola li ka fanoa ka mokhoa o sa reroang.The clamping diameter ranges ho tloha φ5mm-φ250mm, mme bolelele ba ts'ebetso bo tloha ho 140mm-3200mm.

Mohatlana oa li-spindle tse peli tsa CNC lathe

Sesebelisoa sa mochini se sebelisoa haholo ho fetola shaft e khuts'oane le likarolo tse nyane tsa disk.

Ka phetisetso ea othomathiki lipakeng tsa tatellano e 'meli ea li-workpieces, mochini o phethela ts'ebetso ea lesoba le ka hare, selikalikoe sa kantle le lipheletsong tse peli tsa karolo ka ho latellana.

Mochini o ka hlomelloa ka li-manipulator, ho jarolla ka ho iketsa le ho laolla le lisebelisoa tsa polokelo ho phethela ts'ebetso e ikemetseng ea likarolo.t e ntlafalitsoe ka ho khetheha bakeng sa ho fetolela shaft e khuts'oane le likarolo tse nyane tsa poleiti.

Ho tšehetsa Roller Machining Tharollo

Rolara ea tšehetso ke e 'ngoe ea likarolo tsa bohlokoa tsa "mabili a mane le lebanta le le leng" ho li-bulldozers le li-hydraulic excavators.

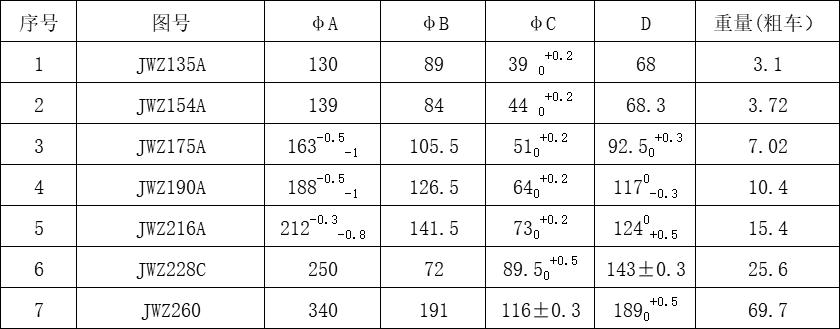

Ho na le litlhaloso tse 4 tsa li-bulldozer roller le lintlha tse 7 tsa li-excavator roller, ho latela mehlala ea rona e teng, re arotsoe ka mekhahlelo e 3:

Ts'ehetso ea lirolara tse hlalosang mefuta le mochini o khothalelitsoeng

| Roller bophara ba bokantle (∮A) | Bolelele ba rolara | Moetso oa Mochini | Max. Clamping bophara | Headstock wide |

| ∮130 | (E ka ba 2D) | SCK205S | ∮175 | 175 |

| ∮139 | Sebaka sa 136 | |||

| ∮163 | Sebaka sa 137 | |||

| ∮188 | Sebaka sa 185 | ∮250 | 280 | |

| ∮212 | Rough 234 (sehlahisoa se felileng 225) | |||

| ∮250 | 248 | |||

| ∮340 | Rough 286 (sehlahisoa se felileng 279) | Ho ntlafatsoa |

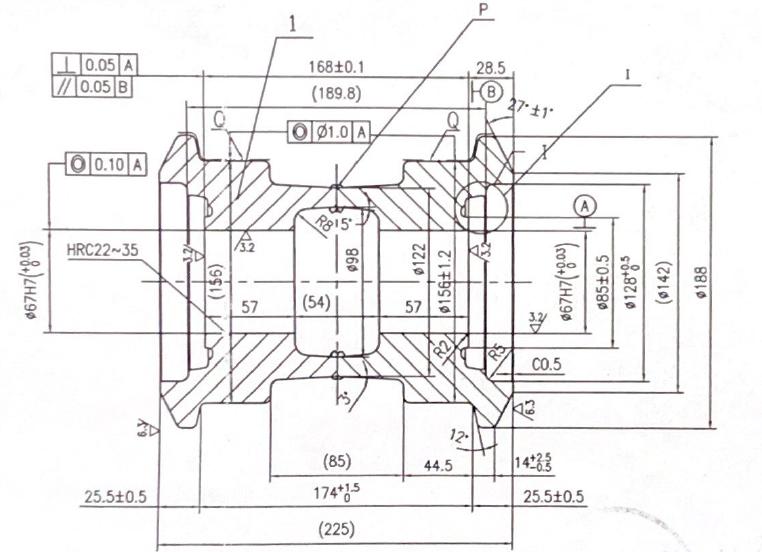

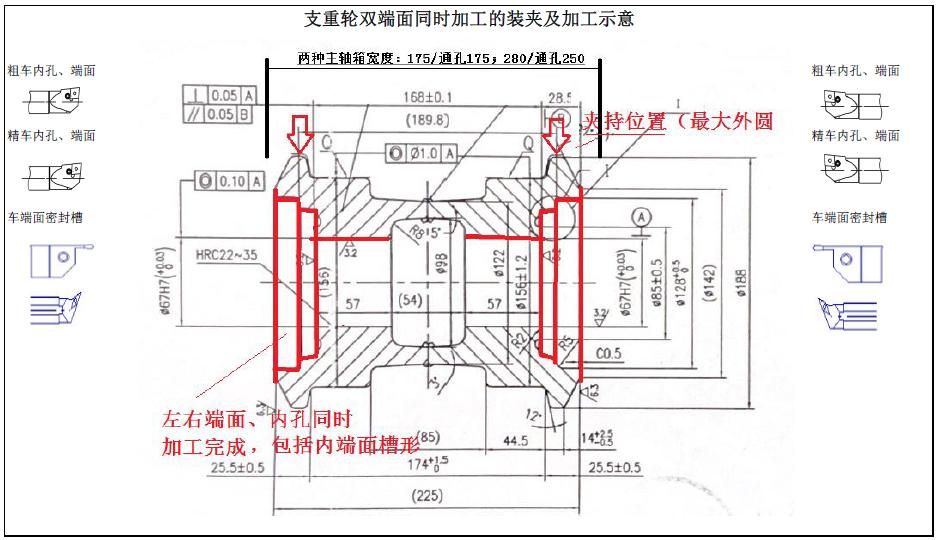

Setšoantšo sa schematic sa rolara e tšehetsang se sebetsoa ke mochini ka tsela e latelang

Selelekela sa Mochini

SCK205S habeli-qetellong CNC lathe

■ Mochini o amohela bethe e 450 e sekametseng, e nang le boits'oaro bo botle le ho tlosoa ha chip ho bonolo.

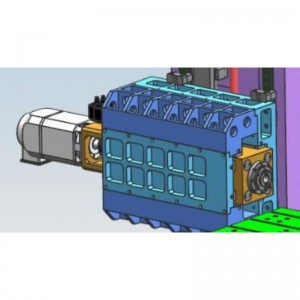

■ Lebokose la ho ohla le kopanya likarolo tse tharo tsa tsamaiso ea ho ohla, sekontiri le silinda ea ho koala, e nang le sebopeho se kopanetsoeng le mosebetsi o tšepahalang. Sesebelisoa se koaletsoe ka hydraulically. Bophara ba clamping ba clamp bo arotsoe ka li-blocks tse peli.

■Sekoti ke sa mofuta oa collet. Manala a ho lokisa a kentsoe ka har'a chuck ea elastic ho nka sebaka sa likarolo tsa ts'ebetso le ho fetola bophara ba clamping. U hloka feela ho khutlisa li-claws tsa ho lokisa, tse potlakileng le tse bonolo.

■ Ho hlokahala lisebelisoa tse ngata tse boring ho latela likarolo tse entsoeng ka mochini. Ho qoba ho kena-kenana le lisebelisoa, turret e hlophisitsoe, 'me bophara bo potolohang ba hlooho ea sehahi bo boholo. E le ho etsa hore turret e be thata haholoanyane, bophahamo bo bohareng ba turret ke 125mm.

■Mochine o na le tsamaiso ea li-channel tse peli, 'me lisebelisoa tse peli tsa ho phomola li ka kopanngoa le spindle ka nako e le' ngoe kapa li arohane ho phethahatsa ts'ebetso ea nako e le 'ngoe kapa e latellanang ea likarolo ka bobeli.

■ E le ho finyella litlhoko tse fapaneng tsa bareki ba fapaneng, sesebelisoa sena sa mochine se ka ba le lisebelisoa tse ka letsohong le letšehali / le letona tseo bareki ba ka li khethang.

■ Ha e le ho kenya le ho laolla, hajoale ke ho kenya le ho laolla ka letsoho. Ha ho nahanoa ka boima bo boima ba mabili a tšehetsang, lisebelisoa tsa mofuta oa truss kapa tsa mofuta o kopaneng tsa ho jarolla le ho theola li ka hlomelloa, ho ipapisitsoe le lipuisano le moreki.

Tlhaloso

| Ntho | Lebitso | Yuniti | Litlhaloso | ||

| Ho sebetsa mefuta-futa | Bophahamo bo boholo ba bethe | mm | Φ550 | Φ600 | |

| Boholo bo potolohang bophara ba 'mele o thellang | Φ350 | ||||

| Boholo ba bophara ba clamping | Φ175 | Φ250 | |||

| Bolelele ba ho sebetsa | Shaft1000;Tube:400 | ||||

| Lebelo la spindle | r/mets | 1000 | 600 | ||

| Hlooho ea hlooho | Bophara ba hlooho ea hlooho | mm | 175 | 280 | |

| Litlhaloso tsa Spindle clamping | Φ130,139,166 | Φ188,212,250 | |||

| Bophara ba lesoba la spindle | Φ175 | Φ250 | |||

| Bophahamo ho tloha setsing sa spindle ho ya fatshe | 1150 | ||||

| Fepa | Tsamaea | X1/X2 | 150/150 | ||

| Z1/Z2 | 480/600 | ||||

| Ho sebeletsa pele | X/Z | mm/r | 0.001~6 | ||

| Kapele-pele | X/Z | m/m | 16 | ||

| Sesebelisoa sa poso | Tsela ea ho khanna | Slewing servo, ho notlela haeteroliki | |||

| Palo ea lisebelisoa | Seteishene | 8 | |||

| Ka ntle thipa boholo ba lisekoere | mm | □32×32 | |||

| Diameter ea boring bar | Φ50 | ||||

| Saese ea mochini (bolelele×bophara× bophahamo) | mm | 4920×1860 (1910)×1900 | |||

| Boima ba mochini | Boima bo kahare | Kg | 6700 | ||

| Boima bo felletseng | 7700 | ||||