CNC Horizontal Heavy Roughing Machining Center HB Series

Likaroloana

Mofuta oa Letlapa Horizontal Machining Center

X / Z axis ke tsela e tsamaeang, Y axis ke tsela e thata.

Lebokose la li-spindle ke sebopeho sa lisebelisoa tse felletseng, tse nang le torque e kholo.

Ts'ebetso ea theko e phahameng, e loketseng bakeng sa machining a thata le a halofo.

Moving Column Heavy Roughing Horizontal Machining Center

Sebopeho sa litšiea tse tsamaeang.

X / Z axis ke tsela e melang, Y axis e ntlafalitsoeng hore e be tsela e thata, e matlafatsang kholomo ea Y-axis.

Ntlafatso ea Gearbox, ts'ebetso ea ho itšeha e ntlafalitsoe haholo.

Ntlafatsa ho mofuta o mocha oa thebe.

Lebelo la spindle le phahamisetsoa ho 4500 rpm.

Setsi sa Machining sa Floor Type Horizontal Machining (mochini o boima oa ho korotla)

Boima bo boima ba ho itšeha le mojaro o boima, sesebelisoa se bohale sa ho khoahlapisa le ho qeta halofo, se tšoarella.

Sebopeho sa fatše, matla a maholo a ho jara.

Lisebelisoa tse felletseng tsa 10-3000 revolutions, torque e ka fihla ho feta 1000N.m.

Ram e ka atolosa 700mm bakeng sa ho sebetsa.

Sesebelisoa se nchocho sa liforomo tsa koloi tse makukuno le tse qetellang. .

Torque ea enjene e eketsoa ka 30-37kw, lisebelisoa lia atolosoa, sebopeho sa strip se ntlafalitsoe, 'me matla a ho itšeha a matlafatsoa haholo.

Litlhaloso tsa Tekheniki

| Ntho | H B 1 7 1 2 ( Tafole ea mosebetsimofuta) | H B 1 8 1 2 (Mofuta oa kholomo e tsamaeang) | HB2516/HB3016/HB3020(Mofuta o emeng fatše) | |

| Sebaka sa tšebetso | ||||

| Leeto la X-axis | mm | 1700 (tafole ea mosebetsi e tsamaea ka ho le letšehali le ka ho le letona) | 1800 (tafole ea mosebetsi e tsamaea ka ho le letšehali le ka ho le letona) | 2500/3000/3000 (kholomo e tsamaea ka ho le letšehali le ka ho le letona) |

| Leeto la Y-axis | mm | 1200 (lebokose la spindle le ea holimo le tlase) | 1200 (lebokose la spindle le ea holimo le tlase) | 1600/1600/2000 (lebokose la spindle le ea holimo le tlase) |

| Leeto la Z-axis | mm | 700 (tafole ea mosebetsi e ea pele le morao) | 800 (kholomo e ea pele le morao) | 700 (pheleu e fetela pele le morao) |

| Spindle center to table | mm | 0-1200 | 130-1330 | 100-1700/100-1700/100-2100 |

| Sefahleho sa spinndle ho isa bohareng ba tafole | mm | 150-850 | 200-1000 | 200 |

| Tataiso ea mofuta oa terene |

| XZ axis linear guide/Y axis hard guide | XZ axis linear guide/Y axis hard guide | |

| Tafole ea mosebetsi | ||||

| Litekanyo tse sebetsang | mm | 1700*850 | 1600*1000 | 2500*1550/3000*1550/3000*1550 |

| Ho jara mojaro o sebetsang | kg | 5000 | 8000 | 30000 |

| Litlhaloso tsa T-slot (bophara* sepakapaka) | mm | 18*150 | 22*150 | 22*200 |

| Spindle | ||||

| Khannamokgoa |

| Lisebelisoa tse feletseng | Lisebelisoa tse feletseng | Lisebelisoa tse feletseng |

| Lebelo le phahameng | rpm | 3000 | 4500 | 3000 |

| Matla a spindle | kW | 15/18.5 | 15/18.5 | 30/37 |

| Boholo ba torque ea spindle | Nm | 286/472 | 473/894 | 498/748 |

| Spindle taper/pin pin |

| BT50-45° | BT50-45° | BT50-45° |

| Phepelo ea koloi | ||||

| Lebelo le phahameng la lebelo la ho sisinyeha X/Y/Z | m/m | 10/10/10 | 10/10/10 | 10/10/10 |

| Lebelo le phahameng la ho itšeha X/Y/Z | m/m. | 6/6/6 | 6/6/6 | 6/6/6 |

| Bonyane qeto | mm | 0.001 | 0.001 | 0.001 |

| Ho nepahala (boemo ba ho kenya tshebetsong GB/T19362.1-2003) | ||||

| X/Y/Z Ho nepahala ha maemo | mm | 0.03 | 0.03 | 0.05 |

| X/Y/Z Pheta-pheta | mm | 0.02 | 0.02 | 0.03 |

| Ba bang | ||||

| Sistimi ea CNC |

| FANUC Oi MF(5) | FANUC Oi MF(5) | FANUC Oi MF(1) |

| matla | kW | 60 | 60 | 75 |

| Bophahamo ba mochini | mm | 3300 | 3300 | 4200/4200/4700 |

| Foolr Area (bolelele*witdth) | mm | 6600*4300 | 5600*4500 | 6000*4500/7000*4500/7000*4500 |

| Boima ba mochini (hoo e ka bang ka.) | kg | 15000 | 20000 | 25T/28T/32T |

Selelekela sa Tlhophiso

(1)FANUC 0i-MF(1)

Tloaelo ea FANUC Oi-MF One CNC System, ts'ebetso e phahameng ea ts'ebetso e phahameng ea ts'ebetso e phahameng ea ts'ebetso, boiketlo bo phahameng ba tšebeliso.Ka nako e ts'oanang, tsamaiso ea SIEMENS / Mitsubishi CNC e ka khethoa ho ea ka litlhoko.

(2) Spindle

BT50 spindle ka lebelo le phahameng, ts'ebetso e phahameng, litšoaneleho tse phahameng tsa ts'ebetso ea torque, ho fihlela litlhoko tsa ts'ebetso ea lisebelisoa tse fapaneng tse tloaelehileng.

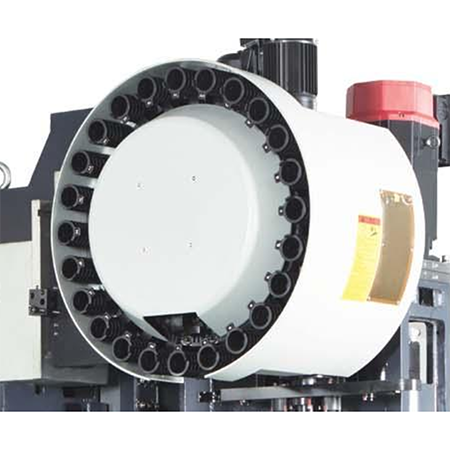

(3)Makasine ea lithulusi

Makasine e tloaelehileng ea lisebelisoa tsa 24T e ka hlomelloa ka makasine ea lisebelisoa tsa 40/60T ho latela litlhoko tsa 'nete tsa ts'ebetso ho fihlela maemo a fapaneng a bareki.