Li-spindle tse peli tsa CNC lathe 208 letoto

Tlhophiso ea Sehlahisoa

Selelekela

TurretDmohlalaPtshebetso

Sebopeho se kopantseng se setle sa Y-axis se tsitsitse haholo, se boima haholo, 'me se na le ts'ebetso e ntle ho feta Y-axis ea interpolation.

·Ho sebetsa hamonate le ho sebetsa hamonate ka sefofane

· Ho bonolo ho sebetsana le libaka tse kobehileng tse kopaneng le li-contours

Ha ho bapisoa le "interpolation Y", "positive Y" e na le melemo e totobetseng ea ho sila sefofane. Motsamao wa "positive Y" Y-axis o shebane le X-axis mme ke motsamao wa axis e le nngwe. Motsamao oa "interpolation Y" Y-axis ke ho kopanya mola o otlolohileng ka motsamao o le mong oa X-axis le Y-axis. Ha ho bapisoa le "positive Y" bakeng sa ho bata ha sefofane se silang, "positive Y" axis processing e hlakile ebile e boreleli.

Ka ho tobaDqoelaSe lumellanangEthutoSpindle

Boima bo phahameng, torque e phahameng, ts'ebetso e phahameng, pheletso e betere, indexing e nepahetseng haholoanyane.

Likarolo tsohle tse kholo tsa mochini li entsoe ka tšepe e entsoeng ka tšepe HT300 e nang le matla a matla a ho monya ka matla.

Likarolo tsa lisebelisoa tsa mochini tse nang le li-spindle tsa motlakase tse khannang ka kotloloho

● Mokotla oa matla a makenete (sine le cosine) ho nepahala ha maemo: metsotsoana e 20 ea arc,

Ho nepahala ha indexing ea C-axis: metsotsoana e 40 ea arc

● Lebelo la ho arabela ka potlako ho qala, ho boloka nako ea sesebelisoa sa mochine le ho ntlafatsa ka katleho bokhoni ba tlhahiso

●Moroalo o monyenyane oa ho khaola, ho boloka matla le ho boloka matla, tšireletso e ntlafetseng ea lisebelisoa tsa mochine le bophelo bo atolositsoeng ba tšebeletso

● Felisa ho sisinyeha ha spindle ka katleho, phello e ntle ea ho leka-lekanya, qetello e ntle, le ho ntlafatsa bokaholimo ba lisebelisoa tsa mosebetsi.

(Melemo ea ho reteleha ho e-na le ho sila, ponahalo e thata ea ho phethoha, bokaholimo ba Ra 0.2μm)

· The spindle motor e na le mochine o pholileng ho thibela tšusumetso ea ho falla ha mocheso le ho netefatsa hore spindle e tsoela pele ho sebetsa mocheso o sa khaotseng.

(Ho nepahala ha nose end runout ho ka hare ho 0.002mm, ho netefatsa ho nepahala ho tsitsitseng haholoanyane)

· Ka morao-mounted ka ho toba ka koloi synchronous spindle, ho feta bonolo ho kenya le tlhokomelo

· A2-5: 7016AC-ka pele tse peli tse ka morao tse peli

· A2-6: ka pele NN3020+100BAR10S, ka morao NN3018

A2-8: ka pele NN3024+BT022B*2, ka morao NN3022

E boima-DutyCastIroneBaseAnd Cbahanyetsi

Likarolo tsohle li ntlafalitsoe ho sebelisoa finite element analysis (FEA) ho fokotsa ho khopama le ho phahamisa matla a ho monya. Li-castings tsa lihlopha tse kholo tsa li-lathe li matlafatsoa ka likhopo ho matlafatsa ho tiea le botsitso ba mocheso. Compact and symmetrical headstock le tailstock castings le ho feta ho matlafatsa ho tiea le ho netefatsa boemo bo nepahetseng le bo pheta-phetoang.

Litlhaloso tsa Tekheniki

| Ntho | Lebitso | Yuniti | 208MS | 208MSY |

| Tsamaea | Max. bophara ba ho potoloha ha bethe | mm | Φ680 | Φ700 |

| Max. bophara ba mochini | mm | Φ370 | Φ300 | |

| Max. bophara ba ho potoloha holim'a sets'oants'o sa sesebelisoa | mm | Φ300 | Φ300 | |

| Max. bolelele ba ho sebetsa | mm | 420 | 400 | |

| Sebaka pakeng tsa litsi tse peli | mm | - | - | |

| Spindle Silinda Chuck | Nko ya spindle | ASA | A2-6 | A2-6 |

| Hydraulic cylinder/chuck | Intshi | 8'' | 8'' | |

| Hlakola ka bophara ba lesoba | mm | Φ79/66 | Φ79/66 | |

| Max. molamu ka bophara ba lesoba | mm | Φ65/52 | Φ65/52 | |

| Spindle Max. lebelo | rpm | 4300 | 4300 | |

| Matla a enjene ea spindle | kw | 18/22 | 18/22 | |

| Spindle motor torque | Nm | 91-227 | 91-227 | |

| Sub-Spindle Silinda Chuck | Sub-Nko ya spindle | ASA | A2-5 | A2-5 |

| Sub-Hydraulic cylinder/chuck | Intshi | 6” | 6” | |

| Sub-Hlakola ka bophara ba lesoba | mm | Φ56 | Φ56 | |

| Sub-Max. molamu ka bophara ba lesoba | mm | Φ46 | Φ46 | |

| Sub-Spindle Max. lebelo | rpm | 5500 | 5500 | |

| Sub-Matla a enjene ea spindle | kw | 17.5 | 17.5 | |

| X/ZN/SAxisFeedPli-arameter | X matla a motlakase | kw | 2.5 | 2.5 |

| Y matla a motlakase | kw | - | 1.2 | |

| Z matla a motlakase | kw | 2.5 | 2.5 | |

| Smatla a motlakase | Kw | 1.2 | 1.2 | |

| Xmaeto a axis | mm | 236 | 204 | |

| Ymaeto a axis | mm | - | 100±50 | |

| Zmaeto a axis | mm | 510 | 492 | |

| Litlhaloso tsa seporo sa X/Z axis | spec | 35 rolara | 35 rolara | |

| Litlhaloso tsa Y axis rail | spec | 25 rolara | 25 rolara | |

| S axis travel | mm | 600 | 600 | |

| Xmotsamao o potlakileng | Mm/mots | 20 | 20 | |

| Zmotsamao o potlakileng | Mm/mots | 20 | 20 | |

| Ymotsamao o potlakileng | Mm/mots | - | 8 | |

| Smotsamao o potlakileng | Mm/mots | 24 | 24 | |

| Matla a servo TurretPli-arameter | Mofuta oa turret ea matla | / | BMT55 | BMT55 |

| Seteishene sa lisebelisoa | / | 12T | 12T | |

| M matla a motlakase | kw | 5.5 | 5.5 | |

| M axis motor torque | Nm | 35 | 35 | |

| Hlooho ea matla Max. lebelo | rpm | 6000 | 6000 | |

| Litlhaloso tsa sets'oants'o sa lisebelisoa tsa kantle tsa bophara | mm | 25*25 | 25*25 | |

| Litlhaloso tsa sets'oants'o sa sesebelisoa sa bophara ba kahare | mm | Φ40 | Φ40 | |

| Nako ea ho fetola lisebelisoa tse haufi | mots | 0.15 | 0.15 | |

| Ho beha ho nepahala | / | ±2” | ±2” | |

| Pheta ho nepahala ha maemo | / | ±1” | ±1” | |

| MohatlaPli-arameter | Lenaneo la hydraulic tailstock | / | - | - |

| Tailstock Max. leetong | mm | - |

| |

| Bophara ba sleeve | mm | - |

| |

| Leeto la matsoho | mm | - |

| |

| Sekhahla sa matsoho | / | - |

| |

| Litekanyo | Ka kakaretso litekanyo | m | 2800*2100*1800 | 2700*2400*2000 |

| Boima ba mochini hoo e ka bang. | kg | 5900 | 5300 | |

| Tse ding | Ho fokotsa molumo oa tanka ea metsi | L | 150 | 150 |

| Matla a pompo ea metsi a pholileng | kw | 0.75 | 0.75 | |

| Bophahamo ba lebokose la hydraulic unit | L | 40 | 40 | |

| Matla a pompo ea oli ea Hydraulic | kw | 1.5 | 1.5 | |

| Bophahamo ba tanka ea oli ea ho tlotsa | L | 2 | 2 | |

| Automatic lubrication pompo matla a motlakase | kw | 50 | 50 |

Selelekela sa Tlhophiso

Ha bonolonyanaTo Use And MorePe matla

● Moralo o ntlafalitsoeng ka botlalo

● E na le i HMI

● E na le theknoloji ea morao-rao ea FANUC ea CNC le servo

● E tloahelehile ka mesebetsi e ikhethileng

●Matla a memori a atolositsoeng

BonoloOf Use

Thibela ho theoha ha mochine ka tšohanyetso ka tlhokomelo e thibelang

●Mesebetsi e ruileng ea ho bolela esale pele liphoso

Fumana sebaka sa phoso habonolo 'me u khutsufatse nako ea ho hlaphoheloa

● Mesebetsi ea ho hlahloba / ea tlhokomelo

Ts'ebetso e phahameng ea ts'ebetso

KhutsufatsoaCycleTime

● Theknoloji ea ho sebetsa ka katleho e phahameng

Fumana ts'ebetso ea boleng bo holimo

Theknoloji ea ts'ebetso e ntle ea sefahleho

● Mosebetsi oa ho hlahloba / oa tlhokomelo

PhahamengOperationRjele

Kamehla tšehetsa lits'ebetso tse fapaneng sebakeng sa ts'ebetso

●FANUC

Motho ka mongScreenIs EasierTo Use

●Ts'ebetso e tloaelehileng ea motho

Mehato e etsoang tšimong ea IoT

● Tšehetso bakeng sa mefuta e mengata ea marang-rang a marang-rang

THKBkaofelaSbasebetsi

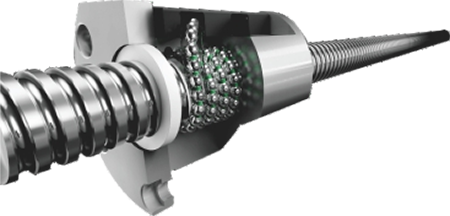

‣ Sehlopha sa C3, se sebelisang sekoti sa bolo e nepahetseng haholo, se nang le kalafo ea linate le sekoti pele ho tsitsipano bakeng sa ho tlosa mokokotlo le ho phahama ha mocheso, ho bonts'a boemo bo botle haholo le ho nepahala ho pheta-pheta.

· Servo motor direct drive ho fokotsa phoso ea backlash.

THKRollerLinearGuide

·P grade ultra-high rigidity SRG precision grade, linear guide zero clearance, arc cutting, bevel cutting, bokaholimo bo batla bo tšoana. E loketse ts'ebetso ea lebelo le holimo, e fokotsa haholo matla a ho khanna a hlokahalang bakeng sa lisebelisoa tsa mochini.

·Ho thella sebakeng sa ho thella, tahlehelo e nyane ea likhohlano, karabelo e hlokolosi, ho nepahala ha maemo a holimo. E ka jara mojaro ka tsela e tsamaeang ka nako e le 'ngoe,' me pina ea ho kopana le pina e ntse e kopana le lintlha tse ngata nakong ea mojaro, 'me ho itšeha ho ke ke ha fokotseha.

·Ho bonolo ho kopanya, ho feto-fetoha ho matla, le mokhoa o bonolo oa ho tlotsa; palo ea ho roala e nyane haholo mme bophelo ba ts'ebeletso bo bolelele.

SKFBtsebe/OilingMachine

·Automatic lubricator e fihlela litlhoko tsa lits'ebetso tse fapaneng, tse loketseng maemo a fapaneng a ts'ebetso, lihlahisoa tse tšepahalang, ts'ebeliso e bonolo.

• Kopana le litlhoko tsa ho jara lubrication mochesong o phahameng, ho thothomela ho matla le tikoloho e kotsi.

Sebaka se seng le se seng sa lubrication se sebelisa distributor ea volumetric proportional ho laola palo ea lubrication, 'me mochine o ka laoloa ke PLC ho fana ka oli ka nepo.