Mekhahlelo e mehlano ea Gantry Machining Center GF Series

Likaroloana

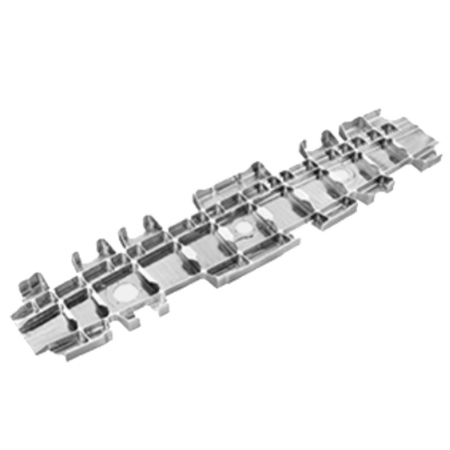

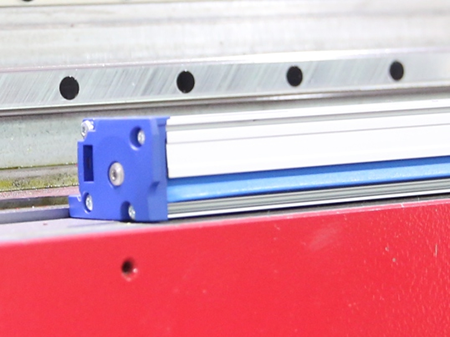

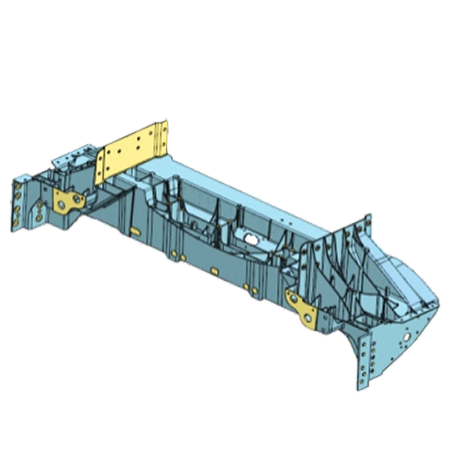

Moralo o Felletseng oa X-axis

Bophahamo ba sethala se ntseng se hola sa liporo tse fapaneng tsa litataiso tsa X-axis li netefatsa ho tiea ho hoholo le ho hlokomela maemo a lebelo le holimo le ka nepo.

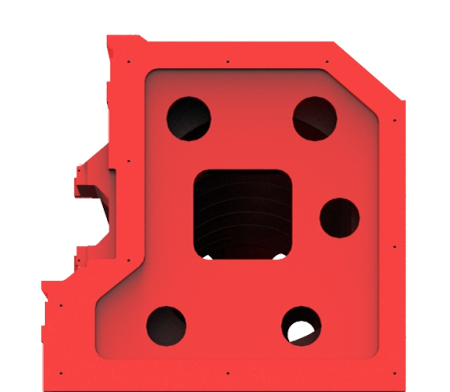

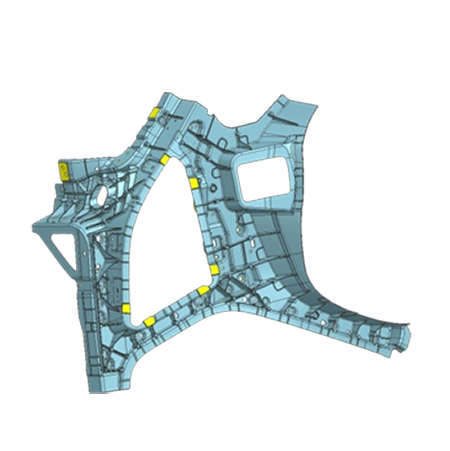

Sebopeho se khethehileng sa UStlatselletsaDmohlala

Hlooho e entsoe ka hlooho e thata e thata, e tlanngoeng ke saddle e bōpehileng joaloka U ka liporo tsa tataiso mahlakoreng ka bobeli ho netefatsa ho tiea ho hoholo ha mochini oa Z-axis.

TheJtlotsaSsefahlehoOf The WlesobaMachineSsebopehoIs Pho lokisaShoveled

Sebaka sa eona sa ho kopana se feta 90% ho netefatsa ho nepahala ha geometri ea mochine oohle

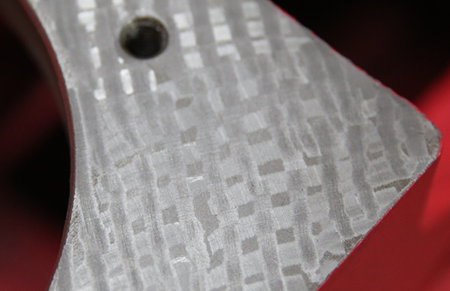

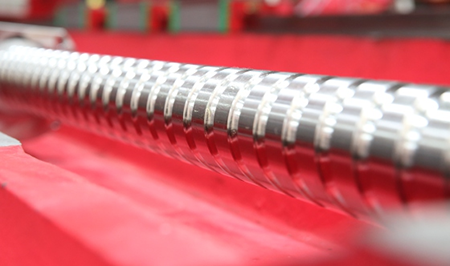

UltraStafoleAnepahalo

The screw rod e amohela mokhoa oa ho kenyafixed pele ho tsitsipano lipheletsong tse peli le ho hohla manonyeletsong a ho lahla ho etsa bonnete ba hore sesebelisoa sa mochini se sebetsa hantle haholo tlas'a maeto a maholo.

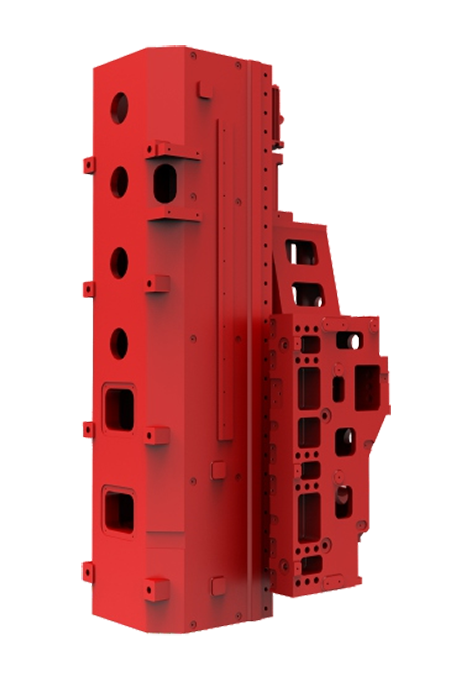

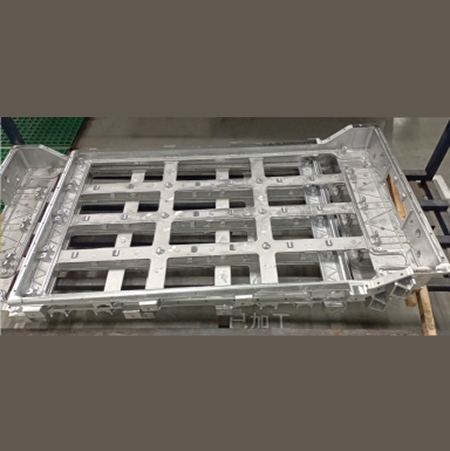

KopantsoengGho kenaAnd Base

Column beam e kopantseng moralo, ho ntlafatsa ho tiea ha mochini le botsitso ba ts'ebetso.

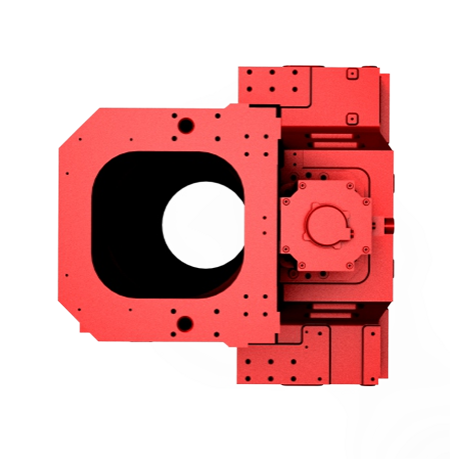

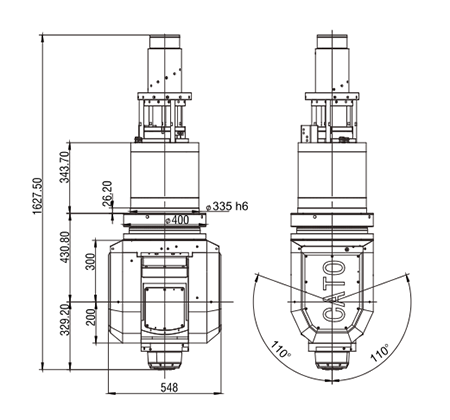

F1 Fork Type Synchronous Two-axis Milling Head

Sebopeho sa sefapano sa symmetrical se na le ho tiea ha sebopeho se phahameng le khatello ea ho sisinyeha ho feta mehlala ea boemo bo tšoanang.

Axis ea B / C e sebelisa enjene ea koloi e otlolohileng le sistimi e phahameng ea ho arabela hydraulic brake, e nang le ho nepahala ho holimo, ho khutlela morao le ho roala zero.

Moralo oa potoloho o pholileng ka metsi le spindle e na le phallo ea metsi e bohareng joalo ka maemo, e ka thibelang liphetoho tsa ho phahama ha mocheso ka nepo le ho netefatsa ho nepahala ho holimo.

Oboikhethelo Tlhophiso

Ho Fumana Sesebelisoa se Senyehileng Makasine

Sehlopha sa ho lemoha se kenngoa laebraring ea lisebelisoa, 'me mokhoa oa ho lemoha le mokhoa oa ho sebetsa o etsoa ka nako e le' ngoe, ntle le ho ama ho otla ha ho sebetsa.

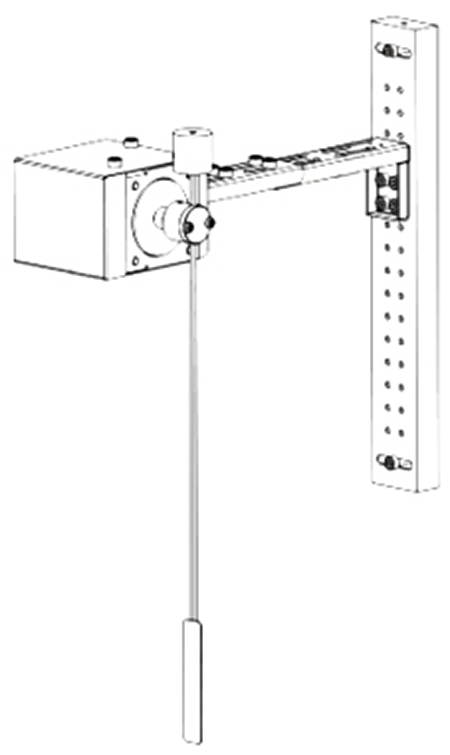

AxialTaba ea boikhethelo Sekala

Letšoao la tlhahiso e lekantsoeng ke digital pulse, e nang le litšobotsi tsa mefuta e mengata ea ho lemoha, ho nepahala ho holimo le lebelo la karabo e potlakileng.

Sistimi ea ho tseba ka Marang-rang

REduce sesebelisoa le nako ea ho loants'a mosebetsi, 'me u boloke 90% ea nako e thusang.

Rho fokotsa lihlahisoa tsa litšila tse bakoang ke phoso ea ho tsamaisana ha lisebelisoa le mosebetsi, le ho ntlafatsa chai.

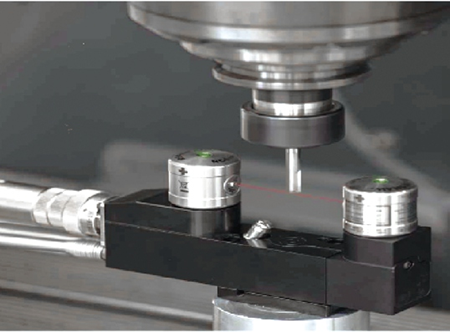

Sesebelisoa sa ho beha lisebelisoa tsa Laser

Pono e potlakileng le e nepahetseng ea boholo ba sesebelisoa ho netefatsa tšebeliso ea nako e telele ntle le ho roala

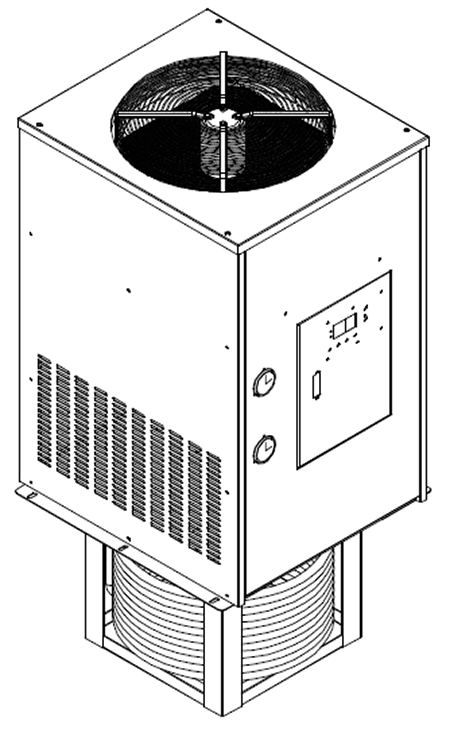

Sesebediswa sa ho Seha Mokelikeli

Thermal displacement of fifixture le workpiece e bakoang ke ho phahama ha mocheso oa ho itšeha fluid ho tla ama ho nepahala ha machining.

Sistimi e ka netefatsa ho phahama ha mocheso oa ho itšeha fluid ka har'a 3-5 ℃

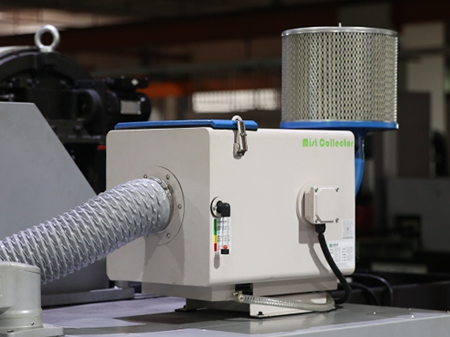

Mokhoa oa ho bokella moholi oa oli

Sekhahla se phahameng sa purication, ts'ebetso e tsitsitseng, lerata le khutsitseng oor.Ka katleho lter moea o qhibilihang ke metsi le mosi oa oli ka har'a workshop le ho hloekisa moea ka ho teba.

Litlhaloso tsa Tekheniki

| Morero | GF2020-5X | GF3020-5X | GF4020-5X | |

| Tsamaea | X/Y/Z maeto a axis | 2000×2000×800mm | 3000×2000×800mm | 4000×3000×1000mm |

| Spindle nko ho setsi sa tafole | 90-890 limilimithara | 80-880 limilimithara | - 100-900 limilimithara | |

| Tafole | Boholo ba tafole | 2000 × 1100mm | 3000 × 1200mm | 4000 × 2000mm |

| Max.tafole mojaro | 2000Kg | 2500kg | 20000kg | |

| Spindle | Spindle taper | HSK-A63 | HSK-A63 | HSK-A100 |

| Max.spindle lebelo | 18000rmp | 18000rmp | 8000rmp | |

| Matla a enjene ea spindle | 30/33.5KW | 30/33.5KW | 70/75KW | |

| Spindle motor torque | 72/85Nm | 72/85Nm | 350/450Nm | |

| Sekhahla sa phepelo | Lebelo le potlakileng la axis ea X/Y/Z | 36/30/30 | 30/30/30 | 15/15/10 |

| Phepo e sehang | 1-12000 | 1-12000 | 1-10000 | |

| ATC | Palo ea sesebelisoa | 24T | 24T | 24T |

| Boholo ba bolelele ba sesebelisoa | 400mm | 400mm | 400mm | |

| Boholo ba bophara ba sesebelisoa | 120 limilimithara | 120 limilimithara | 250 limilimithara | |

| Boholo ba boima ba sesebelisoa | 8kg | 8kg | 15kg | |

| Nako ea phetoho ea sesebelisoa (sesebelisoa ho sesebelisoa) | 4.5S | 4.5S | 5S | |

| Li-axis tse tharo | Tataiso ea X-axis | 45/4 rolara | 45/5 Roller | 45/4 rolara |

| Tataiso ea Y-axis | 55/2 rolara | 55/2 rolara | 65 Rolara | |

| Z-axis tataiso | 55/3 rolara | 55/3 rolara | 65 Rolara | |

| X-axis screw | φ50×16 | φ63×16 | φ80×20 | |

| Y-axis screw | φ50×16 | φ50×16 | φ63×16 | |

| Z-axis screw | φ50×12 | φ50×12 | φ63×16 | |

| Nepahalo | Ho beha ka nepo | ± 0.005/300mm | ± 0.005/300mm | ± 0.005/300mm |

| Ho pheta-pheta boemo bo nepahetseng | ±0.003/300mm ±0.003/300mm | ± 0.003/300mm | ||

| Matla | Tlhokahalo ea matla | Mehato e meraro 380V±10%,50Hz±1%Mohato o meraro 380V±10%,50Hz±1% | Mekhahlelo e meraro 380V±10%,50Hz±1% | |

| Khatello ea moea | ≥6kg/c ≥6kg/c | ≥6kg/c | ||

| Phallo ea moea | ≥0.5mm³/min ≥0.5mm³/min | ≥0.5mm³/mots | ||

| Boholo ba mochini | Boima ba mochini | 20T 22T | 50T | |

Maemo a Ts'ebetso

1.KoloiMkhale

PhahamengProcessingEbofokoli

Nako e le 'ngoe ea clamping ea workpiece, taolo ea nako e le 'ngoe ea 5-axis

Ts'ebetso ea li-angle tse otlolohileng, tse tšekaletseng le tse fapaneng tsa mahala li ka phethoa ka mokhoa o ts'oanang

PhahamengMlintho tse bonahalangRemovalRjele

Lebelo le phahameng, spindle ea matla a phahameng

Boima bo phahameng le litšoaneleho tse phahameng tse matla tsa sebopeho sa mochini oohle

PhahamengCuttingFeedRjele

XYZ axis high speed drive

Boima bo phahameng le litšoaneleho tse phahameng tse matla tsa sebopeho sa mochini oohle

2.SepakapakaStsa nnetePbonono

E kgabaneSsefahlehoProcessingQbophelo

Tšebeliso ea li-axis tse hlano ka nako e le 'ngoe

Bokhoni ba ho sebetsa ka mokhoa o nepahetseng haholo

HaholoShortenProcessingAnd PolishingTime

Linear motor drive

X/Y/Z axis drive e lebelo le phahameng

PhahamengPho lokisa

Seluloana sa lebelo le phahameng, se nang le matla a phahameng

Boima bo phahameng le botsitso bo phahameng ba mohaho oohle oa mochine