Li-axis tse hlano tsa ho sila le ho fetola mochini oa FH letoto

Likaroloana

1.Setsi sa machining sa li-axis tse hlano se ka etsa mesebetsi e mengata mochining o le mong:

phetoho e otlolohileng le e rapameng, e khonang ho sila le ho reteleha; nako e le 'ngoe clamping, multi-process and multi-angle processing and forming.

2.Precision ke boikutlo bo sa feleng

Sebopeho se tsitsitseng haholo le se nepahetseng haholo se boetse se ntlafatsa ho tiea ka kakaretso, 'me mohaho oa motheo o ntlafatsoa ka ho sebelisa lipalo tse fokolang.

3.Easy ts'ebetso le taolo e nepahetseng

Tafole ea ts'ebetso e entsoeng ho latela ergonomics e ka finyella litlhoko tse nepahetseng tsa libaka tse fapaneng tsa ho sebetsa ho latela litlhoko tse fapaneng, ho hlokomela tlhokomelo e haufi-ufi le ho shebella ts'ebetso eohle ea ts'ebetso, ho finyella ts'ebetso e ntle ka ho fetisisa ea ts'ebetso, le ho netefatsa ho nepahala ha taolo. Sistimi ea ts'ebetso e hahelletsoeng e ka hlokomela taolo e tsoelang pele, litokomane le pono ea litaelo, lits'ebetso le data ea sesebelisoa sa mochini, ho etsa hore ts'ebetso e be bonolo le e tsepamisitsoeng haholo tlhahisong ea lihlahisoa.

3.1 Moralo oa ergonomic

E na le ponts'o e 19" e nang le li-touch tse ngata, ho potoloha le ho phahamisa li-angle tse ngata, le skrine ea IPS e bonang ka ho feletseng, le mokhoa oa ho kenya ka mokhoa o tloaelehileng oa khokahanyo ea keyboard ea PC.

3.2Momahano

Mefuta eohle e na le sebopeho se kopaneng sa ts'ebetso, ha ho na tlhoko ea ho ikamahanya le maemo

3.3Ka ho tsoelang pele

Tsamaiso e bohareng ea mosebetsi, ts'ebetso le data ea mochini

3.4E lumellana

Lemoha tšebelisano, phetiso le marang-rang a lifaele ka mefuta e fapaneng

4.E matla 5-axis universal milling hlooho

E eketsehile haholo le ho ntlafala ha liprofaele tsa tšitiso le ho satalla

B-axis e nang le DD motor direct drive e na le YRT e kholoanyane ea ho ntlafatsa ho tiea, e ka finyellang ho itšeha ha torque e phahameng sebakeng sa khokahanyo, e nang le Heidenhain circular grating le taolo e feletseng e koetsoeng, bakeng sa phepo e nepahetseng.

5.Turning le milling worktable

Enjene ea DD e khanna tafole ea ho phethoha le ho sila ka kotloloho ntle le ketane ea phetisetso, ntle le lekhalo le matla a phahameng, 'me e ka phethela ts'ebetso ea ho phethoha le ho sila ka ho koala sesebelisoa sa mochini. Tafole ea rotary e nang le boima bo phahameng e na le mojaro o moholo oa 4T.

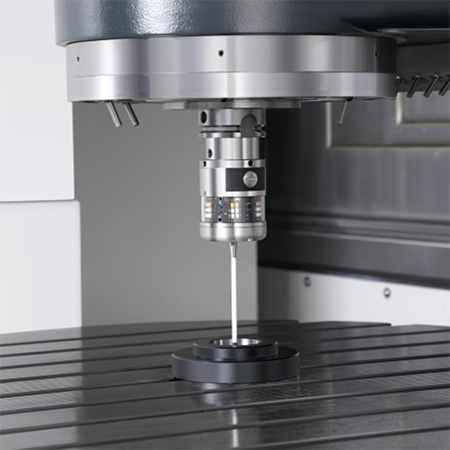

6.Optical touch-trigger probe

E na le OMP60 ultra-small 3D trigger optical probe bakeng sa ho lokisoa le tlhahlobo ea mochini oa mochini, e boloka 90% ea nako e thusang mochining mme e fokotsa sekhahla sa sekhechana.

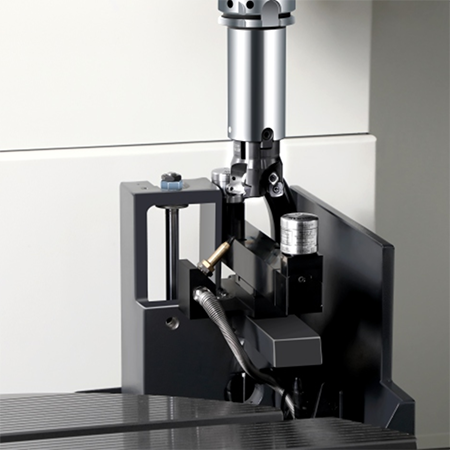

7.Laser sesebelisoa seta

Sesebelisoa sa ho seta sesebelisoa sa laser se sa amaneng le sona se ka phahamisoa le ho theoleloa, 'me sesebelisoa se ka beoa mochining ka bo eona. Puseletso ea sesebelisoa e nchafatsoa ka bo eona, e etsa hore ho nepahala ha ts'ebetso e be e nepahetseng haholoanyane!

Litlhaloso tse Tloaelehileng tsa Tekheniki

| Ntho | FH60P-C | FH80P-C | FH100P-C |

| X/Y/Z maeto a axis | 600mm*800mm*600mm | 800mm×1050mm×800m | 1000mm×1150mm×1000mm |

| Sebaka ho tloha setsing sa hlooho se otlolohileng ho ea ho worktable | 30-630 limilimithara | 39-839 limilimithara | 30mm-1030mm |

| Lebelo la tafole la rotary | 350 rpm | 300rpm | 250 rpm |

| Boholo bo sebetsang | Ø630 limilimithara | Ø880mm | Ø1100mm |

| Max. mojaro oa tafole | Ho feta 2000Kg | Ho lla 3000Kg | Ho feta 4000Kg |

| Ho nka 1000Kg | E boima ba 1500Kg | Ho nka 3000Kg | |

| Swing milling head (B axis) | Standard | Standard | Standard |

| Mokhahlelo oa ho sisinyeha (0=Ho theosa/180=Boemo) | -15 ° ho +180 ° | -15 ° ho +180 ° | -15 ° ho +180 ° |

| Lebelo le lekantsoeng la B-axis | 50rpm | 50rpm | 50rpm |

| Sebaka ho tloha ho nko e otlolohileng ya spindle ho ya tafoleng | 162 mm ho isa ho 962 mm | 162 mm ho isa ho 962 mm | 160 ho isa ho 1160 limilimithara |

| Motlakase spindle Max.speed | 12000rpm | 12000rpm | 10000rpm |

| Matla(S1-100%/S6-40%DC) | 34/42kW | 34/42kW | 42/58kW |

| Matla(S1-100%/S6-40%DC) | 32/192Nm | 32/192Nm | 215/350Nm |

| Sesebelisoa sa sebopeho | HSK-A63 | HSK-A63 | HSK-A100 |

| Tool magazine bokgoni | 40T | 40T | 40T |

| Max.tool diameter/length/weight | Ø85mm/300mm/8Kg | Ø85mm/300mm/8Kg | φ135mm/300mm/12Kg |

| Nako ea ho fetola sesebelisoa (Sesebelisoa ho sesebelisoa) | 4s | 4s | 4s |

| Ho cheka (Ho tloaeleha ka tšepe ea carbon e mahareng) | Ø40 limilimithara | Ø40 limilimithara | Ø50 limilimithara |

| Ho tlanya(Ho tloaeleha ka tšepe ea carbon e mahareng) | M24 | M24 | M40 |

| Spindle taper | 1:10 Taper | 1:10 Taper | 1:10 Taper |

| Ho haola ka potlako | 40m/mots | 40m/mots | 40m/mots |

| X/Y/Z ho nepahala ha maemo | 0.006mr | 0.006mr | 0.006 limilimithara |

| X/Y/Z pheta ho nepahala ha boemo | 0.004mm | 0.004mm | 0.004mm |

| B/C boemo booouraoy | 8'' | 8'' | 8'' |

| B/C pheta boemo ba acouraoy | 4'' | 4'' | 4'' |

| Sesebelisoa sa infrared | Hlahisa OMP60 | Hlahisa OMP60 | Hlahisa OMP60 |

| Too setting gauge(E lekanya haholo sebakeng sa machining) | Renishaw NC4F230 | Renishaw NC4F230 | Renishaw NC4F230 |

| Bophahamo ba mochini (mochini o tloaelehileng) | 3350 limilimithara | 3350 limilimithara | 3650 limilimithara |

| Sebaka sa 'mele o moholo (L*W) | 4800mmx2930mm | 4800mmx2930mm | 5170mmx3340mm |

| Makasine ea lisebelisoa sebakeng seo ho lulang ho sona(L*W) | 1710mmx1350mm | 1710mmx1350mm | 1915mmx1400mm |

| Sebaka se ts'oaretsoeng ke chip conveyor(L*W) | 3070mmx1065mm | 3070mmx1065mm | 3120mmx1065mm |

| Sebaka sa tanka ea metsi (L*W) | 1785mmx1355mm | 1785mmx1355mm | 1785mmx1355mm |

| Sebaka se felletseng sa mochini (ntle le tanka ea metsi) (L*W) | 5610mmx3600mm | 5610mmx3600mm | 5000mmx3750mm |

| Boima ba mochini | 20000Kg | 20000Kg | 30000Kg |

| Tsamaiso ea taolo | Siemens 840Ds | siemens840Ds | siemens840Ds |