Letoto la li-axis tse hlano tse otlolohileng tsa setsi sa mochini sa CBS

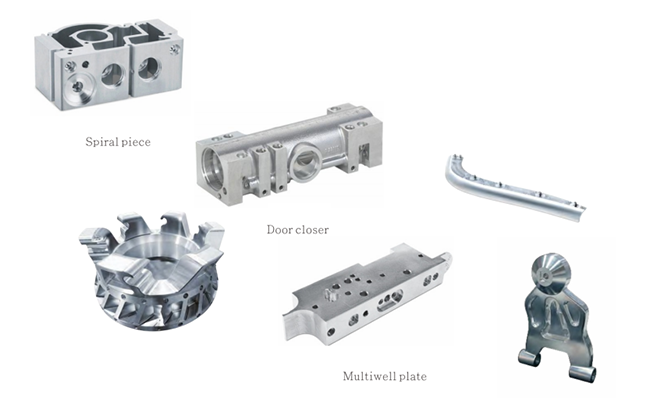

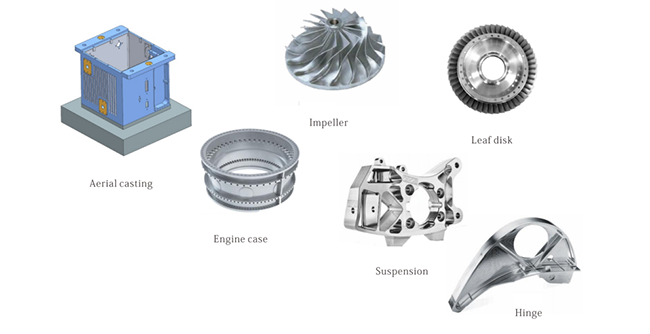

Likaroloana

1.Melemo e kholo ea ts'ebetso

1.1.The X-axis e sebelisa theknoloji ea ho khanna ka ho toba, Y-axis e sebelisa theknoloji e tsamaisanang e tobileng le taolo ea synchronous, e nang le molumo o phahameng, lerata le tlaase, lebelo la ho arabela ka potlako, le ts'ebetso e babatsehang e matla. Li-axis tse tharo tsa X/Y/Z kaofela li amohela maikutlo a holimo a holimo a holimo, ka ho nepahala ha boemo bo holimo.

1.2.Motlakase oa torque e phahameng o khanna A-axis le C-axis ho potoloha, ka ketane ea phetisetso ea zero, backlash ea zero, le ho tiea ho hotle; encoder ea angle e nepahetseng haholo e fihlela boemo bo nepahetseng

1.3.The spindle e nka mohaho o motlakase oa lebelo le phahameng ka lebelo le lerata le tlaase.

2.Mohaho oa borokho o thata-thata

2.1.Letoto la CBS le amohela sebopeho sa sebopeho sa borokho, 'me X / Y / Z e finyella motsamao o sa khaotseng, o sa ameheng ke boima ba axis ea A / C.

2.2. Axis ea A / C e sebetsa ka boithaopo, 'me boima ba mosebetsi ha bo ame li-axis tse ling tse tharo.

2.3.Sebopeho sa gantry le tafole ea swing le rotary e tšehetsoeng lipheletsong tse peli li ka boloka ts'ebetso e phahameng ea nako e telele.

3.Mosebetsi o sebetsang oa ho fetola

4.Tafole ea rotary ea lebelo le phahameng le e thata haholo e hlokomela ho siloa ho sebetsang hantle le ho fetola lisebelisoa tse kopaneng.

Tafole e nepahetseng ea li-axis tse hlano e tsamaisoang ka ho toba ke mochine oa torque e sebelisoa lisebelisoa tsa mochine oa CNC 'me e ka etsa ts'ebetso ea li-axis tse hlano ka nako e le' ngoe. E na le melemo ea lebelo le phahameng, ho nepahala ho phahameng, botsitso le ho tšepahala, le ts'ebetso e bonolo.

5.Ho boloka li-spindles tsa machining tse phahameng tse nepahetseng

Ho tseba mahlale a mantlha le ho nts'etsapele li-spindle ka boits'oaro

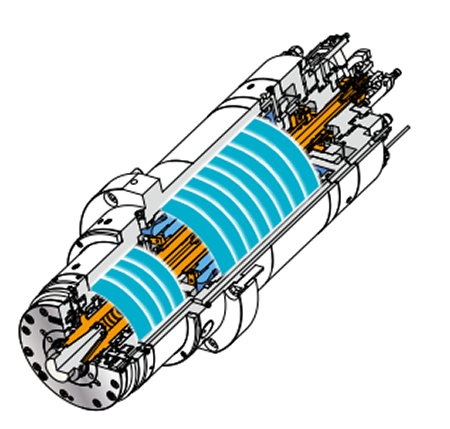

Oturn e na le boiphihlelo ba theknoloji ea mantlha ebile e na le bokhoni ba ho rala, ho etsa le ho kopanya li-spindle. Ka workshop e tsitsitseng ea mocheso oa 1000m2 le mokhoa o rarahaneng oa tlhahiso ea modular, li-spindle tsa Oturn li na le litšobotsi tsa ho tiea ho hoholo, lebelo le phahameng, matla a phahameng, torque e phahameng le ho tšepahala ho phahameng.

HSKE40/HSKA63/HSKA100 e hahiloeng ka har'a spindle e ikemetseng e amoheloa. Ka har'a marang-rang a ho potoloha ha spindle, ho thothomela le ho sisinyeha ho tlosoa ho finyella ho nepahala ho tsitsitseng ho sebetsa ka lebelo le phahameng le nako e telele. Spindle e sebelisa pholiso e qobelloang ho pholisa enjene le libere tse ka pele le tse ka morao.

6.Mohaho oa motlakase o hahiloeng ka hare

Ka ho felisa lisebelisoa tsa ho khanna, ho thothomela nakong ea ho potoloha ka lebelo le phahameng ho ka fokotsoa, ka hona ho ntlafatsa ho nepahala ha sebaka se entsoeng ka mochine le ho lelefatsa bophelo ba sesebelisoa.

7.Spindle taolo ea mocheso

Ka ho potoloha oli e pholileng e laoloang ke mocheso, ho falla ha mocheso oa spindle ho bakoang ke mocheso o hlahisoang ke karolo e 'ngoe le e' ngoe ho ka hatelloa, kahoo ho thibela liphetoho ho nepahala ha mochine.

8.Ho etella pele lefats'e ka li-motor tse nang le mela

Li-motors tsa linear

8.1.E na le mochine o motlakase, ha ho na ho kopana ha mochine nakong ea ho sisinyeha, ha ho na tahlehelo ea mechine, ha ho na phetiso ea morao-rao, le lebelo la ho arabela ka potlako.

8.2.Absolute optical scale bakeng sa taolo e feletseng e koetsoeng.

'Musi oa grating o felletseng, ho nepahala ha boemo ba nanometer, tharollo e fihlang ho 0.05μm, ho fihlela taolo e felletseng ea loop.

9.Moqapi o motle oa ergonomic

Ho ipapisitsoe le moralo oa ergonomic, ho bonolo ho basebelisi ho e sebelisa le ho ntlafatsa ts'ebetso le ts'ebetso.

9.1. phihlello e babatsehang

E le ho ntlafatsa ts'ebetso ea ho fumana sebaka sa mosebetsi, sekoahelo se ka tlaase ho monyako oa ts'ebetso se khutlisetsoa ka lehlakoreng la sebaka sa mosebetsi ho netefatsa sebaka se lekaneng sa ho sebetsa.

9.2.Fensetere e kholo bakeng sa ho shebella habonolo ea ho sebetsa

Fesetere e kholo e etsa hore ho be bonolo ho bona boemo ba ts'ebetso ea workpiece. Haholo-holo, tiiso ea khafetsa ea maemo a ho itšeha le liphetoho ts'ebetsong nakong ea ts'ebetso ea tokiso e ka boela ea phethoa habonolo, ho ntlafatsa katleho ea mosebetsi.

9.3.Tlhahiso e bohareng ea lihlopha tsa tlhokomelo

E le ho ntlafatsa ts'ebetso ea ho fumana sebaka sa mosebetsi, sekoahelo se ka tlaase ho monyako oa ts'ebetso se khutlisetsoa ka lehlakoreng la sebaka sa mosebetsi ho netefatsa sebaka se lekaneng sa ho sebetsa.

9.4.Wide tshebetso monyako bakeng sa ho fihlella bonolo ka crane

Ha ho etsoa ts'ebetso e kang ho fetola li-workpiece, mosebetsi oa basebetsi o ka fokotsoa, 'me ka nako e ts'oanang, ho na le sebaka se lekaneng sa ho sebetsa ha u sebelisa crane.

9.5.Pleasant le botsoalle tshebetso phanele

Phanele ea ts'ebetso e feto-fetohang e lumellanang le bophahamo ba 'mele oa motho e lumella opereishene ho sebetsa le ho hlophisa mochini ka mokhoa o motle.

Litlhaloso tsa Tekheniki

| Ntho | CBS200 | CBS200C | CBS300 | CBS300C | CBS400 | CBS400C | |

| Tsamaea | X/Y/Z maeto a axis | 300*350*250 | 300*350*250 | 460*390*400 | |||

| Sebaka ho tloha sefahlehong sa spindle ho ea setsing sa mosebetsi | 130-380 | 130-380 | 155-555 | ||||

| Spindle | Spindle taper | E40 | E40 | E40 | |||

| Max.spindle lebelo | 30000 | 30000 | 30000 | ||||

| Matla a spindle (a tsoelang pele/S325%) | 11/13.2 | 11/13.2 | 11/13.2 | ||||

| Spindle motor torque (e tsoelang pele/S325%) | 11.5/13.8 | 11.5/13.8 | 11.5/13.8 | ||||

| Fepa |

Lebelo le lebelo la X/Y/Z axis (m/min)

| 48/48/48 | 48/48/48 | 30/30/30 | |||

| Phepelo e sehang(mm/min) | 1-24000 | 1-24000 | 1-12000 | ||||

| Tafole ea rotary | Bophara ba tafole ea rotary | 200 | 300 | 400 | |||

| Boima ba moroalo bo lumelletsoeng | 30 | 20 | 40 | 25 | 250 | 100 | |

| A-axis tilting angle | ±110° | ±110° | ±110° | ||||

| Ho potoloha ha C-axis | 360° | 360° | 360° | ||||

| A-axis rated/max.speed | 47/70 | 47/70 | 30/60 | ||||

| A-axis Rated/max.torque | 782/1540 | 782/1540 | 940/2000 | ||||

| C-axis rated/max.speed | 200/250 | 1500/2000 | 200/250 | 1500/2000 | 100/150 | 800/1500 | |

| C-axis rated/max.torque | 92/218 | 15/30 | 92/218 | 15/30 | 185/318 | 42/60 | |

| A-axis positioning accuracy/peatability | 10/6 | 10/6 | 10/6 | ||||

| C-axis positioning accuracy/peatability | 8/4 | 8/4 | 8/4 | ||||

| ATC | Tool magazine bokgoni | 16 | 16 | 26 | |||

| Tool max. bophara/ bolelele | 80/200 | 80/200 | 80/200 | ||||

| Max.tool boima | 3 | 3 | 3 | ||||

| Nako ea ho fetola lisebelisoa (sesebelisoa ho sesebelisoa) | 4 | 4 | 4 | ||||

| Boraro- axis | Tataiso ea X-axis (bophara ba tataiso ea mola/ palo ea li-slider) | 30/2 | 30/2 | 35/2 | |||

| Tataiso ea X-axis (bophara ba tataiso ea mola/ palo ea li-slider) | 35/2+30/2 | 35/2+30/2 | 45/2 | ||||

| Z-axis tataiso (bophara ba tataiso ea mola/ palo ea li-slider) | 25/2 | 25/2 | 35/2 | ||||

| Matla a enjene ea X-axis (a tsoelang pele/max.) | 1097/2750 | 1097/2750 | φ40×10 (sekere) | ||||

| Matla a motlakase a Y-axis (a tsoelang pele/max.) | 3250/8250 | 3250/8250 |

| ||||

| Matla a enjene a Z-axis (a tsoelang pele/max.) | 1033/1511 | 1033/1511 |

| ||||

| Ho nepahala | Ho beha ho nepahala | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Pheta-pheta | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Mohloli oa matla | Matla a phepelo ea matla | 25 | 30 | 25 | 30 | 30 | 35 |

| Khatello ea moea | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ||||

| Boholo ba mochini | Boholo ba mochini | 1920*3030*2360 | 1920*3030*2360 | 2000*2910*2850 | |||

| Boholo ba mochini (ho kenyeletsoa chip conveyor le lisebelisoa tse ling tsa peripheral) | 3580*3030*2360 | 3580*3030*2360 | 3360*2910*2850 | ||||

| Boima ba 'mele | 4.8T | 4.8T | 5T | ||||

| Ntho | CBS500 | CBS500C | CBS650 | CBS650C | CBS800 | CBS800C | |

| Tsamaea | X/Y/Z maeto a axis | 500*600*450 | 650*800*560 | 800*910*560 | |||

| Sebaka ho tloha sefahlehong sa spindle ho ea setsing sa mosebetsi | 130-580 | 110-670 | 100-660 | ||||

| Spindle | Spindle taper | A63 | A63 | A63 | |||

| Max.spindle lebelo | 20000 | 20000 | 20000 | ||||

| Matla a spindle (a tsoelang pele/S325%) | 30/34 | 30/34 | 30/34 | ||||

| Spindle motor torque (e tsoelang pele/S325%) | 47.7/57.3 | 47.7/57.3 | 47.7157.3 | ||||

| Fepa | Lebelo le lebelo la X/Y/Z axis (m/min)

| 48/48/48 | 48/48/48 | 48/48/48 | |||

| Phepelo e sehang(mm/min) | 1-24000 | 1-24000 | 1-24000 | ||||

| Tafole ea rotary | Bophara ba tafole ea rotary | 500 | 650 | 800 | |||

| Boima ba moroalo bo lumelletsoeng | 600 | 240 | 800 | 400 | 1000 | 400 | |

| A-axis tilting angle | ±110° | ±110° | ±110° | ||||

| Ho potoloha ha C-axis | 360° | 360° | 360° | ||||

| A-axis rated/max.speed | 60/80 | 40/8C | 40/80 | ||||

| A-axis Rated/max.torque | 1500/4500 | 3500/7000 | 3500/7000 | ||||

| C-axis rated/max.speed | 80/120 | 600/1000 | 50/80 | 450/800 | 50/80 | 450/800 | |

| C-axis rated/max.torque | 355/685 | 160/240 | 964/1690 | 450/900 | 964/1690 | 450/900 | |

| A-axis positioning accuracy/peatability | 10/6 | 10/6 | 10/6 | ||||

| C-axis positioning accuracy/peatability | 8/4 | 8/4 | 8/4 | ||||

| ATC | Tool magazine bokgoni | 25 | 30 | 30 | |||

| Tool max. bophara/ bolelele | 80/300 | 80/300 | 80/300 | ||||

| Max.tool boima | 8 | 8 | 8 | ||||

| Nako ea ho fetola lisebelisoa (sesebelisoa ho sesebelisoa) | 4 | 4 | 4 | ||||

| Boraro- axis | Tataiso ea X-axis (bophara ba tataiso ea mola/ palo ea li-slider) | 35/2 | 45/2 | 45/2 | |||

| Tataiso ea X-axis (bophara ba tataiso ea mola/ palo ea li-slider) | 45/2 | 45/2 | 45/2 | ||||

| Z-axis tataiso (bophara ba tataiso ea mola/ palo ea li-slider) | 35/2 | 35/2 | 35/2 | ||||

| Matla a enjene ea X-axis (a tsoelang pele/max.) | 2167/5500 | 3250/8250 | 3250/8250 | ||||

| Matla a motlakase a Y-axis (a tsoelang pele/max.) |

|

|

| ||||

| Matla a enjene a Z-axis (a tsoelang pele/max.) | 2R40*20 (sekere) | 2R40*20 (sekere) | 2R40*20 (sekere) | ||||

| Ho nepahala | Ho beha ho nepahala | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Pheta-pheta | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Mohloli oa matla | Matla a phepelo ea matla | 40 | 45 | 55 | 70 | 55 | 70 |

| Khatello ea moea | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ||||

| Boholo ba mochini | Boholo ba mochini | 2230*3403*3070 | 2800*5081*3500 | 2800*5081*3500 | |||

| Boholo ba mochini (ho kenyeletsoa chip conveyor le lisebelisoa tse ling tsa peripheral) | 2230*5540*3070 | 2800*7205*3500 | 2800*7205*3500 | ||||

| Boima ba 'mele | 11T | 15T | 15.5T | ||||

Maemo a Ts'ebetso

1.Indasteri ea Likoloi

2.Sepakapaka

3.Mechini ea Kaho