Litsi tse hlano tsa Vertical Machining Center CV Series

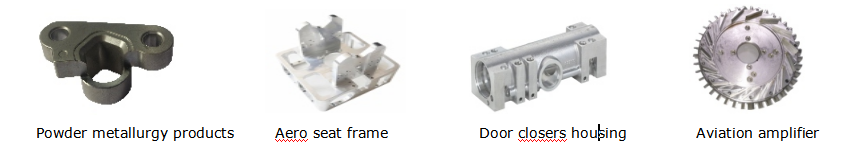

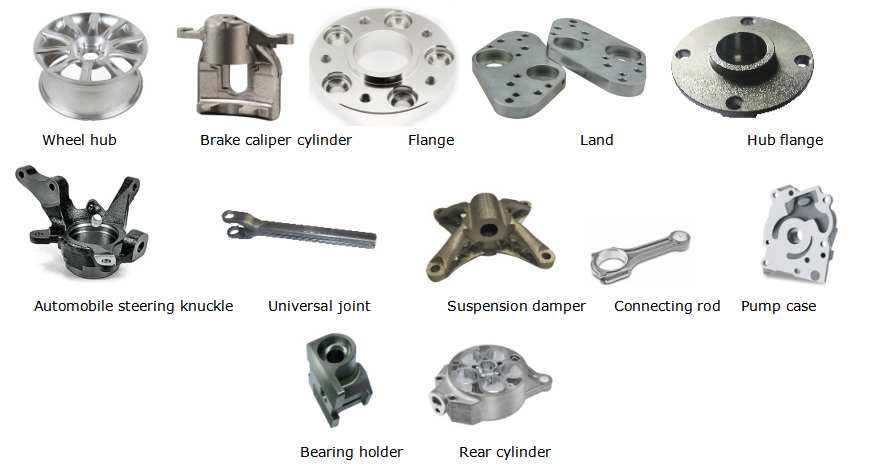

Likaroloana

Kenyelletso ea mochini

Letoto la li-CV tsa li-axis tse hlano tse otlolohileng li na le litšobotsi tsa ho tiea ho hoholo, ho nepahala ho phahameng le ho sebetsa hantle haholo. Kholomo e amohela moralo oa herringbone o nang le span e kholo, e ka ntlafatsang haholo matla a ho kobeha le a torsional a kholomo; setulo sa mosebetsi se nka nako e lekaneng ea li-slider 'me se tingoa holim'a metsi, e le hore matla a benche ea mosebetsi a tšoanelehe' me boima bo ntlafatsoe; bethe e nka karolo ea trapezoidal cross-section, e fokotsa Setsi sa matla a khoheli se ntlafatsa matla a torsional; mochine kaofela o sebelisa finite element analysis ho rala karolo ka 'ngoe ho fana ka botsitso bo botle ka ho fetisisa.

Phallo e potlakileng ka ho fetisisa ea li-axis tse tharo e ka fihla ho 48M / min, nako ea phetoho ea sesebelisoa sa TT ke 2.5S feela, makasine ea sesebelisoa e tletse ka ho feletseng bakeng sa 24t. E loketse mefuta e fapaneng ea 2D le 3D concave-convex e nang le libopeho tse rarahaneng le li-cavities tse rarahaneng le bokaholimo. E boetse e loketse ho sila, ho cheka, ho atolosa, ho bora, ho Tapping le mekhoa e meng ea ho sebetsana le mekhoa e metle bakeng sa lihlopha tse nyenyane le tse mahareng tsa mefuta e mengata ea ho sebetsa le ho hlahisa, hape e ka sebelisoa ka mela e ikemetseng bakeng sa tlhahiso ea boima.

Pontšo e matla ea setšoantšo sa pina ea lisebelisoa, pontšo e bohlale ea temoso, ho itlhahloba le mesebetsi e meng e etsa hore tšebeliso le tlhokomelo ea mochine oa mochine o be bonolo haholoanyane le ka potlako; Bokhoni ba ho bala bo eketsehile ho ea ho mela e 3000/motsotsoana, e leng se nolofatsang phetiso e potlakileng le e sebetsang hantle le ts'ebetso ea marang-rang ea mananeo a matla a maholo.

RTCP (Rotation Tool center Point) ea setsi sa machining sa li-axis tse hlano ke mosebetsi oa ho laola lintlha tsa lisebelisoa. Ka mor'a ho bulela ts'ebetso ea RTCP, molaoli o tla fetoha ho tloha qalong ho laola sefahleho sa ho qetela sa sesebelisoa ho ea ho laola ntlha ea ntlha ea sesebelisoa. Keletso ea sesebelisoa e latelang e ka lefella linearity e bakoang ke axis ea rotary. Phoso ea ho thibela ho thulana. Sebakeng sa A sa workpiece, setsi sa setsi sa axis ea sesebelisoa se fetoha ka ho toba ho tloha sebakeng se otlolohileng ho ea sebakeng se otlolohileng. Haeba phoso ea linear e sa lokisoe, ntlha ea sesebelisoa e tla kheloha ntlha ea A kapa e kenelle mosebetsing, e baka kotsi e tebileng. Hobane motsamao o tsoelang pele oa axis ea swing le axis ea rotary e baka liphetoho sebakeng sa ntlha ea A, sebaka sa ntlha sa ntlha ea sesebelisoa lenaneong se tlameha ho lokisoa ho netefatsa hore lihokahanyo tsa boemo ba lisebelisoa li lula li sa fetohe ho ea ho A, joalo ka ha eka. ntlha ea sesebelisoa e tsamaea le ntlha A. , ena ke ntlha ea Tool e latelang.

Ts'ebetso ena e na le maemo a 0 ~ 9, boemo ba 9 ke bo nepahetseng ka ho fetesisa, athe boemo ba 1 - 8 bo lefella phoso ea morao ea servo, 'me e fana ka tsela ea ts'ebetso boreleli bo nepahetseng.

Ho sebetsa ka lebelo le phahameng le ho nepahala ho hoholo ha mahlakore a mararo

Spindle ea lebelo le phahameng, taolo ea machining ea 3D arc e ka bala li-2000blocks esale pele le tokiso ea tsela e boreleli bakeng sa machining a lebelo le holimo le a holimo.

High Rigidity Sebopeho

Ntlafatsa sebopeho sa sebopeho 'me u ntlafatse kabo ho matlafatsa botsitso ba mochini. Sebopeho sa sesebelisoa sa mochini le kholomo le ts'ebeliso ea kabo ke sebopeho se nepahetseng ka ho fetesisa ka tlhahlobo ea CAE. Mehato e fapaneng e ntlafalitsoeng e sa bonahaleng kantle e bonts'a bokhoni bo tsitsitseng ba ho itšeha boo lebelo la ho ohla le ke keng la bo bontša.

Litlhaloso tsa Tekheniki

| Ntho | unit | CV200 | CV300 | CV500 | |

| Tsamaea

| X/Y/Z maeto a axis | mm | 500×400×330 | 700*600*500 | 700×600×500 |

| Sebaka ho tloha sefahlehong sa spindle ho ea sebakeng se ka sebetsoang | mm | 100-430 | 150-650 | 130-630 | |

| Sebaka se hole ho tloha setsing sa spindle ho ea fihla holim'a seporo sa tataiso | mm | 412 | 628 | 628 | |

| Sebaka se seholo pakeng tsa setsi sa spindle sa A-axis 90 ° le sebaka sa disk sa C-axis | mm | 235 | 360 | 310 | |

| 3 axis feed

| X/Y/Z axis e falla ka potlako | m/m | 48/48/48 | 48/48/48 | 36/36/36 |

| Sekhahla sa ho fokotsa lijo | mm/min | 1-24000 | 1-24000 | 1-24000 | |

| Spindle

| Litlhaloso tsa spindle (diameter ea ho kenya / mokhoa oa phetisetso) | mm | 95/ho toba | 140/Ka ho toba | 140/Ka ho toba |

| Spindle taper | mm | BT30 | BT40 | BT40 | |

| Lebelo la spindle | r/mets | 12000 | 12000 | 12000 | |

| Matla a spindle (a tsoelang pele/S3 25%) | kW | 8.2/12 | 15/22.5 | 15/22.5 | |

| Spindle Motor Torque (E Tsoelang Pele/S3 25%) | Nm | 26/38 | 47.8/71.7 | 47.8/71.7 | |

| Makasine ea lisebelisoa

| Bokhoni ba limakasine | T | 21T | 24T | 24T |

| Nako ea ho fetola lisebelisoa (TT) | s | 2.5 | 4 | 4 | |

| Max.Tool diameter(sesebediswa se felletseng/sesebediswa se se nang letho) | mm | 80 | 70/120 | 70/120 | |

| Max.Tool length | mm | 250 | 300 | 300 | |

| Max. Boima ba sesebelisoa | kg | 3 | 8 | 8 | |

| Tataiso

| Tataiso ea X-axis (boholo / palo ea li-slider) | mm | 30/2 | 35/2 roller | 45/2 roller |

| Tataiso ea Y-axis (litekanyo / bongata ba li-slider) |

| 30/2 | 35/2 roller | 45/2 roller | |

| Tataiso ea Z-axis (litekanyo / bongata ba li-slider) |

| 30/2 | 35/2 roller | 45/2 roller | |

|

Screw

| X-axis screw |

| Φ28×16 | Φ40×16 | Φ40×16 |

| Y-axis screw |

| Φ28×16 | Φ40×16 | Φ40×16 | |

| Z axis screw |

| Φ32×16 | Φ40×16 | Φ40×16 | |

| Ho nepahala

| Ho beha ho nepahala | mm | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Pheta-pheta | mm | ±0.003/300 | ±0.003/300 | ±0.003/300 | |

| 5 akse

| Mokhoa oa ho khanna oa Turntable |

| Moter o tobileng | Roller cam | khamera ea roller |

| Diameter e fetohang | mm | Φ200 | Φ300*250 | φ500*400 | |

| Boima ba moroalo bo lumelletsoeng ba turntable (ka ho rapama / e sekametseng) | kg | 40/20 | 100/70 | 200 | |

| A/C-axis max. lebelo | rpm | 100/230 | 60/60 | 60/60 | |

| A-axis positioning/ Ho pheta-pheta | arc-sec | 10/6 | 15/10 | 15/10 | |

| Boemo ba C-axis/ho pheatability | arc-sec | 8/4 | 15/10 | 15/10 | |

| Lubrication

| Lubrication unit capacity | L | 1.8 | 1.8 | 1.8 |

| Mofuta oa ho arola oli |

| volumetric | Ho tlotsa ka mafura | volumetric | |

| Ba bang

| Tlhokahalo ea moea | kg/c㎡ | ≥6 | ≥6 | ≥6 |

| Phallo ea mohloli oa moea | mm3/min | ≥0.2 | ≥0.4 | ≥0.4 | |

| matla a betri | KVA | 10 | 22.5 | 26 | |

| Boima ba Mochini (Bo akaretsang) | t | 2.9 | 7 | 8 | |

| Litekanyo tsa Mechini (L×W×H) | mm | 1554×2346×2768 | 2248*2884*2860 | 2610×2884×3303 | |

Mohlala oa Ts'ebetso

1.Indasteri ea Likoloi

2.Precision fixture

3.Indasteri ea sesole