Mochini oa ho Sila oa GM5X-I 5- axis CNC

Setšoantšo se ka sehloohong sa mohaho oa mochine

Sebaka sa kopo

Mochine ona o hlahisa sehahi sa ho qetela sa milling le li-drill, tse loketseng ho sebetsana le lisebelisoa tse thata tsa alloy le lisebelisoa tse phahameng tsa tšepe.

Ho etsa lithulusi le lipotoloho tsa regrinding

Mehaho e tloaelehileng ea ho qetela: grooving, tšehetso, rake sharpening, ho chorisa moeli o ka tlase, digitization, regrinding.

1. Litlhaloso tsa tekheniki

| № | Litaba | Tlhokahalo | Nomoro | Yuniti |

| 1.1 | Litekanyo tsa Workpiece | |||

| 1.1.1 | Bolelele ba ho koala | ≤ | 230 | mm |

| 1.1.2 | Clamping bophara | pakeng tsa | 2-20 | mm |

| 1.1.3 | Bolelele ba ho sila | ≤ | 150 | mm |

| 1.1.4 | Bophara ba ho sila | pakeng tsa | 0.3-12 | mm |

| 1.2 | Ho sila Spindle | |||

| 1.2.1 | Mofuta oa koloi | Nepahetse | khannoa ka kotloloho | - |

| 1.2.2 | Matla | matla a lekantsoeng | 13.6 | kW |

| 1.2.3 | Ho phodisa | Nepahetse | Oli e pholile | - |

| 1.2.4 | Ho laola lebelo la lebili la ho sila | Nepahetse | E se nang mohato-lebelo | - |

| 1.2.5 | Lebelo | pakeng tsa | 0-10000 | rpm |

| 1.2.6 | Palo ea lihlooho tsa ho sila ka spindle | Nepahetse | 2 | likhomphutha |

| 1.3 | Lebili la ho sila | |||

| 1.3.1 | Diameter | ≤ | 150 | mm |

| 1.3.2 | Boholo ba mabili a ho sila ho 'ngoe | ≤ | 4 | likhomphutha |

| 1.3.3 | Mabili a silang bophara ba spindle | Nepahetse | 25 | mm |

| 1.3.4 | Phepelo ea litsidifatso tse laoloang ke lenaneo | Nepahetse | Ee | - |

| 1.3.5 | Palo ea li-nozzles tse pholileng | ≥ | 3 | likhomphutha |

| 1.4 | Sistimi ea li-clamping tsa workpiece | |||

| 1.4.1 | Sistimi ea clamping | Nepahetse | Hydraulic, automatic | - |

| 1.4.2 | Kolete e kokotang | Nepahetse | SCHAUBLIN W20 | - |

| 1.4.3 | Mofuta oa koloi | Nepahetse | khannoa ka kotloloho | - |

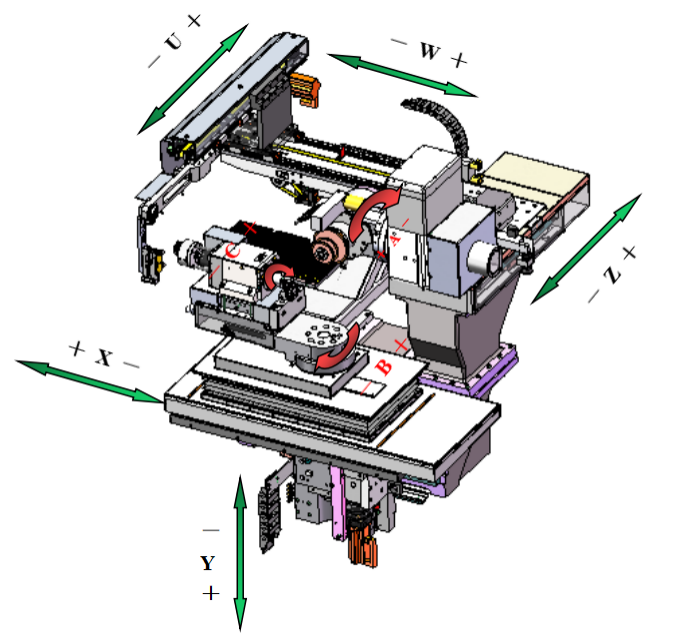

| 1.5 | Axis parameters | |||

| 1.5.1 | Mofuta | Nepahetse | linear | - |

| 1.5.2 | Leeto la X-axis | ≤ | 280 | mm |

| 1.5.3 | Leeto la Z-axis | ≤ | 130 | mm |

| 1.5.4 | Leeto la Y-axis | ≤ | 230 | mm |

| 1.5.5 | Qeto ea axis ea XYZ | Nepahetse | 0.0001 | mm |

| 1.5.6 | XYZ lebelo la axis | ≤ | 10 | m/m |

| 1.5.7 | Leeto la A-axis | ≤ | 360 | tekanyo |

| 1.5.8 | Qeto ea A-axis | Nepahetse | 0.0001 | tekanyo |

| 1.5.9 | A-axis lebelo | ≤ | 300 | rpm |

| 1.5.10 | Leeto la B-axis | ± | 210 | likhato |

| 1.5.11 | B-axis lebelo | ≤ | 12 | rpm |

| 1.6 | Sistimi ea ho kenya le ho laolla | |||

| 1.6.1 | Sistimi ea ho kenya le ho laolla | Nepahetse | Letsoho la robotiki la mofuta oa truss | - |

| 1.6.2 | Palo ea literei | Nepahetse | 2 | likhomphutha |

| 1.6.3 | Ho jarolla ka ho iketsa le ho theola bophara ba karolo ea mosebetsi | Pakeng tsa | 2-12 | mm |

| 1.6.4 | Ho jarolla ka ho iketsa le ho laolla bolelele ba mosebetsi | ≤ | 40-200 | mm |

| 1.6.5 | Boholo ba palo ea li-workpieces | ≤ | 300 | likhomphutha |

| 1.6.6 | Software | Nepahetse | Ee | - |

| 1.7 | Likarolo tse ling | |||

| 1.7.1 | Bokhoni ba ho bona li-workpiece ho lisebelisoa tsa mochini | Nepahetse | Ee | - |

| 1.7.2 | Sistimi ea ho lubrication e ikemetseng | Nepahetse | Ee |

|

| 1.7.3 | Lebone la pontšo ea Tricolor | Nepahetse | Ee | - |

| 1.8 | Taba ea boikhethelo | |||

| 1.8.1 | Thepa ea ho arola moholi oa oli | Nepahetse | Taba ea boikhethelo | - |

| 1.9 | Taolo | |||

| 1.9.1 | Tsamaiso ea taolo | Nepahetse | NUCN-IM8+ | - |

| 1.9.2 | Phanele ea ts'ebetso | Nepahetse | Skrine se thetsoang | - |

| 1.9.3 | Digital control axis | Nepahetse | Ee | - |

| 1.9.4 | Pontšo ea mebala | Nepahetse | Ee | - |

| 1.9.5 | Boholo ba Pontšo | Nepahetse | 19 | intshi |

| 1.10 | Mojule oa software ea ho sila lisebelisoa | |||

| 1.10.1 | Li-milling cutters tse bonolo | Nepahetse | Ee | - |

| 1.10.2 | Lisebelisoa tse bonolo | Nepahetse | Ee | - |

| 1.10.3 | Batlisisa mokhoa oa ho lemoha ka bohona | Nepahetse | Ee | - |

| 1.11 | Lisebelisoa tsa lisebelisoa tsa motlakase | |||

| 1.11.1 | Palo ea li-volts | Nepahetse | 380±10% | V |

| 1.11.2 | Khafetsa | Nepahetse | 50±10% | Hz |

| 1.11.3 | Matla | ≤ | 25 | KW |

| 1.12 | Litekanyo | |||

| 1.12.1 | Bolelele | ≤ | 2 000 | mm |

| 1.12.2 | Bophara | ≤ | 2 800 | mm |

| 1.12.3 | Bophahamo | ≤ | 2 200 | mm |

| 1.12.4 | Boleng | ≤ | 4 750 | kg |

2. Lethathamo le tloaelehileng la tlhophiso

| № | Litaba | Mohlala | Brand | Nomoro | ||

| 2.1 | Sesebelisoa sa mochini | |||||

| 2.1.1 | Sebopeho sa X-axis | |||||

| 2.1.1.1 | - Screw rod | Customized | NSK | 1pcs | ||

| 2.1.1.2 | - Seporo | 1×MR25-A2-760-20-20-G2-V2+BRK+SOSPL | SCHNEEBERGER | 2pcs | ||

| 2.1.2 | Sebopeho sa Y-axis | |||||

| 2.1.2.1 | - Screw rod | Customized | NSK | 1pcs | ||

| 2.1.2.2 | - Seporo | 1×MR35-C2-600-20-20-G2-V2+MRK | SCHNEEBERGER | 2pcs | ||

| 2.1.3 | Sebopeho sa Z-axis | |||||

| 2.1.3.1 | - Screw rod | Customized | NSK | 1pcs | ||

| 2.1.3.2 | - Seporo | 1×MR25-A2-850-20-20-G2-V2+BRK+SOSPL | SCHNEEBERGER | 2pcs | ||

| 2.1.4 | Tlhophiso ea A-axis | |||||

| 2.1.4.1 | - Angle encoder | ECN113 | HEIDENHAIN | 1pcs | ||

| 2.1.4.2 | - Enjene ea ho khanna ka kotloloho | MSP-1000-2-002-158 | HIWIN | 1pcs | ||

| 2.1.5 | B-axis turntable | Customized | GuTian | 1pcs | ||

| 2.1.6 | Permanent magnet double head spindle ea motlakase | Matla a lekantsoeng 7.1KW | Chuangyun | 1 likhomphutha | ||

| 2.1.7 | Lisebelisoa tse tharo tsa axis truss manipulator | - | Chuangyun | 1pcs | ||

| 2.1.8 | Terei | 148-LP-D4 | Chuangyun | 2pcs | ||

| 2.1.9 | Terei | 148-LP-D6 | Chuangyun | 2pcs | ||

| 2.1.10 | Terei | 148-LP-D8 | Chuangyun | 2pcs | ||

| 2.1.11 | Mohlahare o otlang | D0.5-3.2/D3.0-7.0/D7-13 | Chuangyun | 1 sete | ||

| 2.1.12 | Ho nepahala ho phahameng V-block | (3-5) | Chuangyun | 1pcs | ||

| 2.1.13 | Ho nepahala ho phahameng V-block | (5-7) | Chuangyun | 1pcs | ||

| 2.1.14 | Ho nepahala ho phahameng V-block | (6-12) | Chuangyun | 1pcs | ||

| 2.1.15 | Collet | D4W20 (80-00004) | SCHAUBLIN | 1pcs | ||

| 2.1.16 | Batla | TS150 | HEIDENHAIN | 1pcs | ||

| 2.1.17 | Thupa ea ho sila (bolelele) | 119×∅31.75×∅96mm | Chuangyun | 1pcs | ||

| 2.1.18 | Thupa ea ho sila (e khuts'oane) | 87×∅31.75×∅96mm | Chuangyun | 1pcs | ||

| 2.1.19 | Sefehla moea | - | YUEDE | 1pcs | ||

| 2.1.20 | Lebone la pontšo ea Tricolor | DC24V | Schneider | 1pcs | ||

| 2.1.21 | Phallo | SI5000 | IFM | 1pcs | ||

| 2.1.22 | Kenya matla a khethehileng | 15KW | NEWCOM | 1pcs | ||

| 2.1.23 | Sehlopha sa li-valve tsa electromagnetic | M4GE280R-CX-E20D-5-3 | CKD | 1 sete | ||

| 2.1.24 | X,Y, Z-axis mokhoa oa ho lubrication oa boiketsetso | - | Taiwan | 1 sete | ||

| 2.2 | tlhophiso ea sistimi ea CNC | |||||

| 2.2.1 | BOXPC | IMPC00S/P1 | Newcon | 1pcs | ||

| 2.2.2 | Sesefa sa matla | AGOFIL024A | NUM | 1pcs | ||

| 2.2.3 | Sesefa sa matla | AGOFIL001S | NUM | 1pcs | ||

| 2.2.4 | Khanyetso | AGORES008 | NUM | 1pcs | ||

| 2.2.5 | Motlakase o ka sehloohong oa tsamaiso | MDLL3015N00AN0I | NUM | 1pcs | ||

| 2.2.6 | Mokhanni oa servo | MDLUX021B1CAN0I | NUM | 4pcs | ||

| 2.2.7 | B-axis servo motor | ZLS1002-H60-D3M1-NNSB-D16E40 | NUM | 1pcs | ||

| 2.2.8 | A-axis enjene | MSP-1000-2-002-158 | NUM | 1pcs | ||

| 2.2.9 | Y-axis servo motor | ZLS1454-H30-DCM1-SNSB-D24E50 | NUM | 1pcs | ||

| 2.2.10 | X/Z-axis servo motor | ZLS1153-H30-D3M1-NNSB-D19E40 | NUM | 2pcs | ||

| 2.2.11 | U/W axis servo driver | ZLS0754-H60-D2M1-SNSB-D14E30 | NUM | 2pcs | ||

| 2.2.12 | V-axis servo motor | ZLS0754-H60-D2M1-SNSB-D14E30 | NUM | 1pcs | ||

| 2.2.13 | Banyalani | EX-1100 | Newcon | 1pcs | ||

| 2.2.14 | Kenyeletso | EX-210H | Newcon | 2pcs | ||

| 2.2.15 | Sephetho | EX-310H | Newcon | 2pcs | ||

| 2.2.16 | Mojule oa ho kenya analog | EX-4054 | Newcon | 1pcs | ||

| 2.2.17 | Terminator | EX-TRE01 | Newcon | 1pcs | ||

| 2.2.18 | Phanele ea ts'ebetso | IMOP4106/H | Newcon | 1pcs | ||

| 2.2.19 | NCK | IM8+ | Newcon | 1pcs | ||

| 2.2.20 | NCK | IMSO100006 | Newcon | 1pcs | ||

| 2.2.21 | NCK | IMSO100008 | Newcon | 1pcs | ||

| 2.2.22 | NCK | IMSO100012 | Newcon | 1pcs | ||

| 2.2.23 | NCK | IMPA100586 | Newcon | 1pcs | ||

| 2.2.24 | NCK | IMSO100373 | Newcon | 1pcs | ||

| 2.2.25 | NCK | IMSO100375 | Newcon | 1pcs | ||

| 2.2.26 | NCK | IMSO100335 | Newcon | 1pcs | ||

| 2.2.27 | NCK | IMSO100519 | Newcon | 1pcs | ||

| 2.2.28 | NCK | IMSO100392 | Newcon | 1pcs | ||

| 2.2.29 | NCK | IMSO100331 | Newcon | 1pcs | ||

| 2.2.30 | NCK | IMSO100535 | Newcon | 1pcs | ||

| 2.2.31 | NCK | IMSO100520 | Newcon | 1pcs | ||

| 2.2.32 | NCK | IMSO100560 | Newcon | 1pcs | ||

| 2.3 | Tlhophiso e tloaelehileng ea software ea ho sila | |||||

| 2.3.1 | Sekhahla se bonolo sa ho sila | Chuangyun e iketseditseng | 1pcs | |||

| 2.3.2 | Boro e bonolo | Chuangyun e iketseditseng | 1pcs | |||

| 2.3.3 | Ho hlahloba ho thulana ha 3D ka mochine oa 3D oa ho etsisa | Chuangyun e iketseditseng | 1pcs | |||

| 2.3.4 | Ketsiso ea lisebelisoa tsa 3D | Chuangyun e iketseditseng | 1pcs | |||

| 2.3.5 | Batlisisa ka boiketsetso | Chuangyun e iketseditseng | 1pcs | |||