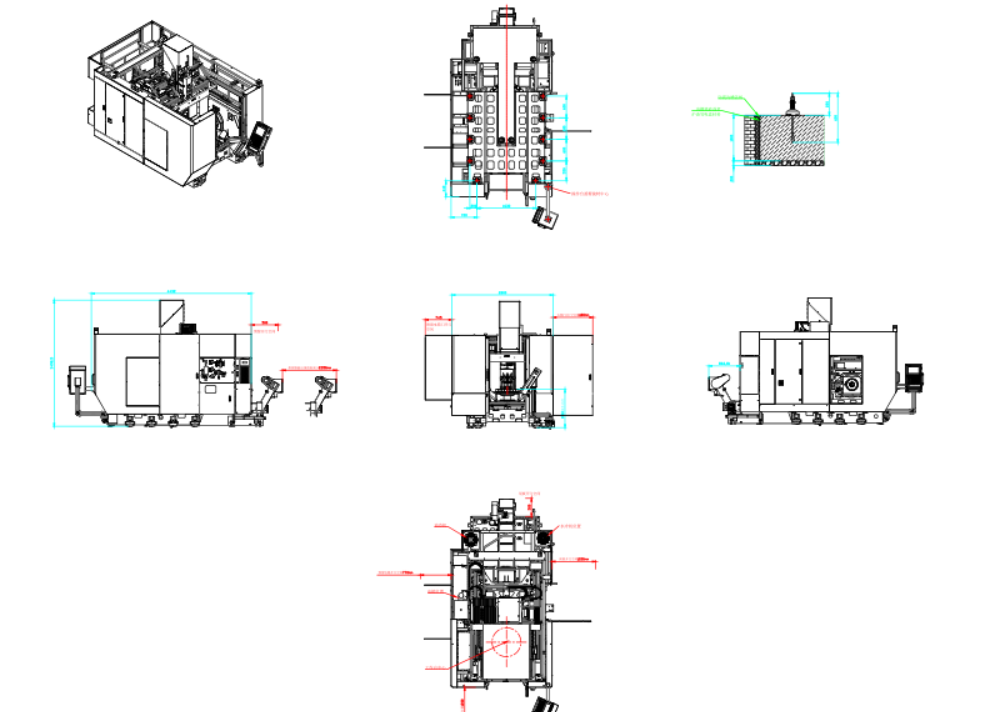

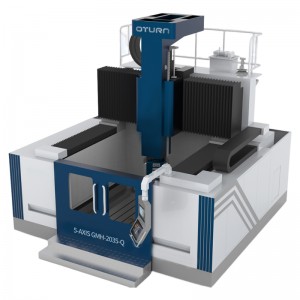

Setsi sa machining sa mofuta oa borokho bo phahameng ka lebelo le phahameng CBS650

1.Mochine Overview

CBS650 ke lebelo le phahameng, ts'ebetso e phahameng, borokho bo nepahetseng bo phahameng ba mofuta oa 5-axis machining center e nang le boima bo phahameng, ho nepahala ho phahameng le ho sebetsa hantle haholo. Mochini oohle o entsoe ka tlhahlobo ea lintlha tse fokolang ho fana ka ts'ebetso e ntle ka ho fetisisa ea botsitso.

Lilepe tse tharo tsa ho falla ka potlako 48 M / min, TT sesebelisoa se fetola nako feela 4S, makasine ea sesebelisoa e tletseng mojaro oa lihora tsa 24 sesebelisoa sa phetoho ntle le mochine oa alamo le mochine o mong le o mong oa teko ea mochine oa makhetlo a 3 ka tlhahlobo ea element, ho etsa bonnete ba hore mochine o sebetsa hantle ebile o sebetsa hantle. botsitso bo sa feleng ka mora ho tloha femeng. E loketse mefuta eohle ea libopeho tse rarahaneng tsa mefuta e 'meli le e meraro ea concave le convex e hlokang khokahano ea 5-axis bakeng sa ts'ebetso ea mantlha, mme ho feta moo, e loketse tlhahiso ea mefuta e mengata e nyane le e mahareng, hape e ka kena. the automatic line bakeng sa tlhahiso ea bongata.

Tsamaiso ea morao-rao ea TNC640 e tsoang HEIDENHAIN, e nang le pontšo e kholo ea LCD ea 15-inch, pontšo e bohlale ea temoso le ho itlhahloba, e etsa hore mochine o be bonolo haholoanyane ho o sebelisa le ho o boloka; taolo ea likarolo tse ngata pele ho bala e loketse ka ho khetheha bakeng sa ts'ebetso ea lenaneo le potlakileng le le leholo, 'me e tšehetsa phetiso ea marang-rang le USB, e thusang phetiso e potlakileng le e sebetsang ea mananeo a matla le ts'ebetso ea inthanete.

2.Main parameter

| Ntho | Yuniti | tlhaloso | |

| Trevel | X/Y/Z maeto a axis | mm | 800×900×560 |

| Sebaka ho tloha pheletsong ea spindle ho isa bokaholimong ba tafole | mm | 110-670 | |

| Sebaka se seholo ho tloha setsing sa spindle ho ea holim'a tafole ho 90° ea A-axis | mm | 560 | |

| Boholo ba mefuta ea mochini | mm | φ800*560 | |

| C-axis turntable

| Diameter ea sebaka sa disc | mm | Φ650 |

| Turntable T-slot/bophara ba senotlolo sa tataiso | mm | 14H7/25H7 | |

| Mojaro o lumelletsoeng | kg | 350 | |

| Phepelo ea li-axis tse tharo | X/Y/Z-axis ea ho falla ka potlako | m/m | 48/48/48 |

| Ho fokotsa lebelo la phepelo | mm/min | 0-12000 | |

| tlhapi | Litlhaloso tsa spindle (mokhoa oa ho phahamisa bophara / mokhoa oa phetisetso) | mm | 170/ka hare ho patiloe |

| Spindle taper bore | mm | A63 | |

| Lebelo le phahameng la spindle | r/mets | 18000 | |

| Matla a spindle (a tsoelang pele/S3 15%) | kW | 22/26 | |

| Spindle motor torque (e tsoelang pele/S3 15%) | Nm | 56.8/70 | |

| Makasine ea lisebelisoa | Tool magazine bokgoni |

| 30T |

| Nako ea phapanyetsano ea lisebelisoa (TT) | s | 4 | |

| Max. bophara ba sesebelisoa | mm | 80/120 | |

| Max. bolelele ba sesebelisoa | Mm | 300 | |

| Max. boima ba sesebelisoa | kg | 8 | |

| Seporo sa Tataiso | Tsela ea X-axis (boholo/palo ea li-slide) | mm | 452 |

| Tsela ea Y-axis (boholo/palo ea li-slide) | 45/2 | ||

| Tsela ea Z-axis (boholo/palo ea li-slide) | 35/2 | ||

|

Lilepe tse tharo | X linear motor thrust (e tsoelang pele/boholo) | N | 3866/10438 |

| Y linear motor thrust (e tsoelang pele/boholo) | N | 3866/10438 | |

| Z-axis screw | N | 2R40*20 (Khoele e habeli) | |

|

Akse e mehlano | C-axis e reitiloe/lebelo le phahameng | rpm | 50/90 |

| C axis rated/maximum cutting torque | Nm | 964/1690 | |

| Ho nepahala ha boemo ba axis/ho pheta-pheta | arc-sec | 10/6 | |

| Ho nepahala ha boemo ba C-axis/ho pheta-pheta | arc-sec | 8/4 | |

| Ho nepahala ha li-axis tse tharo

| Ho beha ho nepahala | mm | 0.005/300 |

| Pheta ho nepahala ha maemo | mm | 0.003/300 | |

| Sistimi ea Lubrication

| Lubrication unit capacity | L | 0.7 |

| Mofuta oa lubrication |

| Ho tlotsa ka mafura | |

| Mokelikeli o sehang | Bokhoni ba tanka ea metsi | L | 300 |

| Ho khaola li-parameter tsa pompo |

| 0.32Mpa×16L/min | |

| ba bang | Tlhokahalo ea moea | kg/c㎡ | ≥6 |

| Sekhahla sa ho phalla ha mohloli oa moea | mm3/min | ≥0.5 | |

| Matla a phepelo ea matla | KVA | 45 | |

| Boima ba mochini (bo kopantsoeng) | t | 17 | |

| Boemo (L×W×H) | mm | 2760×5470×3500 | |

3.Tlhahiso e tloaelehileng

| 序号 | Lebitso |

| 1 | Sistimi ea Siemens 840D |

| 2 | Tshebetso ya ho tlanya ka nako e le nngwe |

| 3 | X/Y/Z/A/C sisteme e koetsoeng ka botlalo ea loop |

| 4 | X/Y/C axis direct drive motor control |

| 5 | Sistimi ea taolo ea mocheso oa X / Y / C ea axial |

| 6 | Mokhoa oa ho laola mocheso oa spindle |

| 7 | Tšireletso ea li-spindle overload |

| 8 | Letlapa le koetsoeng ka botlalo |

| 9 | Sistimi ea senotlolo sa mamati |

| 10 | Monyako o ikemetseng oa makasine ea lisebelisoa |

| 11 | Automatic grease lubrication system |

| 12 | Leseli le khanyang la mosebetsi oa LED |

| 13 | Setlhophiso sa lisebelisoa tsa mochini le sesebelisoa sa ho seta lisebelisoa (Medron) |

| 14 | Sisteme ea ho phahamisa chip |

| 15 | Sistimi ea ho foka ka mochini |

| 16 | Sistimi ea ho fafatsa ka peripheral |

| 17 | Sistimi e phodileng |

| 18 | Sesebelisoa se tloaelehileng le lebokose la lisebelisoa |