Lilemong tsa morao tjena, tlhoko ea 'maraka e fetohile butle-butle ho tloha lihlahisoa tsa setso ho ea ho lihlahisoa tse nang le litšobotsi tsa taolo ea lipalo, bohlale le botala.

1. Mochini oa ho phunyaboemo ba 'maraka oa lihlahisoa

Hajoale, litlhoko tsa basebelisi bakeng sa lihlahisoa tsa mochini oa ho cheka li bonts'a maemo a fapaneng.Basebelisi ba bang ba sebelisa lisebelisoa tse khethehileng ho nkela lisebelisoa tse akaretsang sebaka, 'me basebelisi ba bang ba khetha lihlahisoa tse nang le litšenyehelo tse phahameng haholo.Leha ho le joalo, litlhoko tse akaretsang tsa lihlopha tsa basebelisi bakeng sa lihlahisoa tsa mochini oa ho cheka ke li-automation tse ntle, taolo ea lipalo, Bokhoni bo phahameng, boholo bo boholo le mekhoa e meng.

Ho ea ka pono ea tsoelo-pele ea moruo ea Asia e hlokahalang, e nyaneMochini oa CNC oa ho cheka le oa ho silali lebeletsoe hore li tsoele pele ho boloka tsoelo-pele e tsitsitseng le e potlakileng ka nako e telele.Mechini ea ho cheka le ho sila ea CNC e fetohile khetho ea pele bakeng sa ho cheka le ho sebetsana le likarolo tsa tsamaiso ea porous joalo ka likoloi, literene, likepe, sefofane, mechini ea kaho le liindasteri tse ling, haholo-holo bakeng sa li-laminate tse telele, maballo a longitudinal, tšepe ea sebopeho le likarolo tsa tubular. .

2. Boemo ba 'maraka oamochine o hlabanglihlahisoa

Lilemong tsa morao tjena, thekenoloji ea mechine e hlabang le ea ho sila le mechine ea ho sila fatše le e monate lapeng le linaheng tse ling e tsoetse pele ka potlako haholo, e khetholloang ke ntlafatso e tsoelang pele ea sebopeho sa sehlahisoa, ts'ebeliso e sa feleng ea theknoloji e ncha, ho teba ha tekanyo. ea ts'ebetso ea ts'ebetso e kopaneng, ntlafatso e tsoelang pele ea lebelo le bokhabane, le ho toboketsa tlhahiso e ntle.Libakeng tse latelang tsa bohlokoa, lihlahisoa tsa mochini o tenang li na le lits'ebetso tsa bohlokoa:

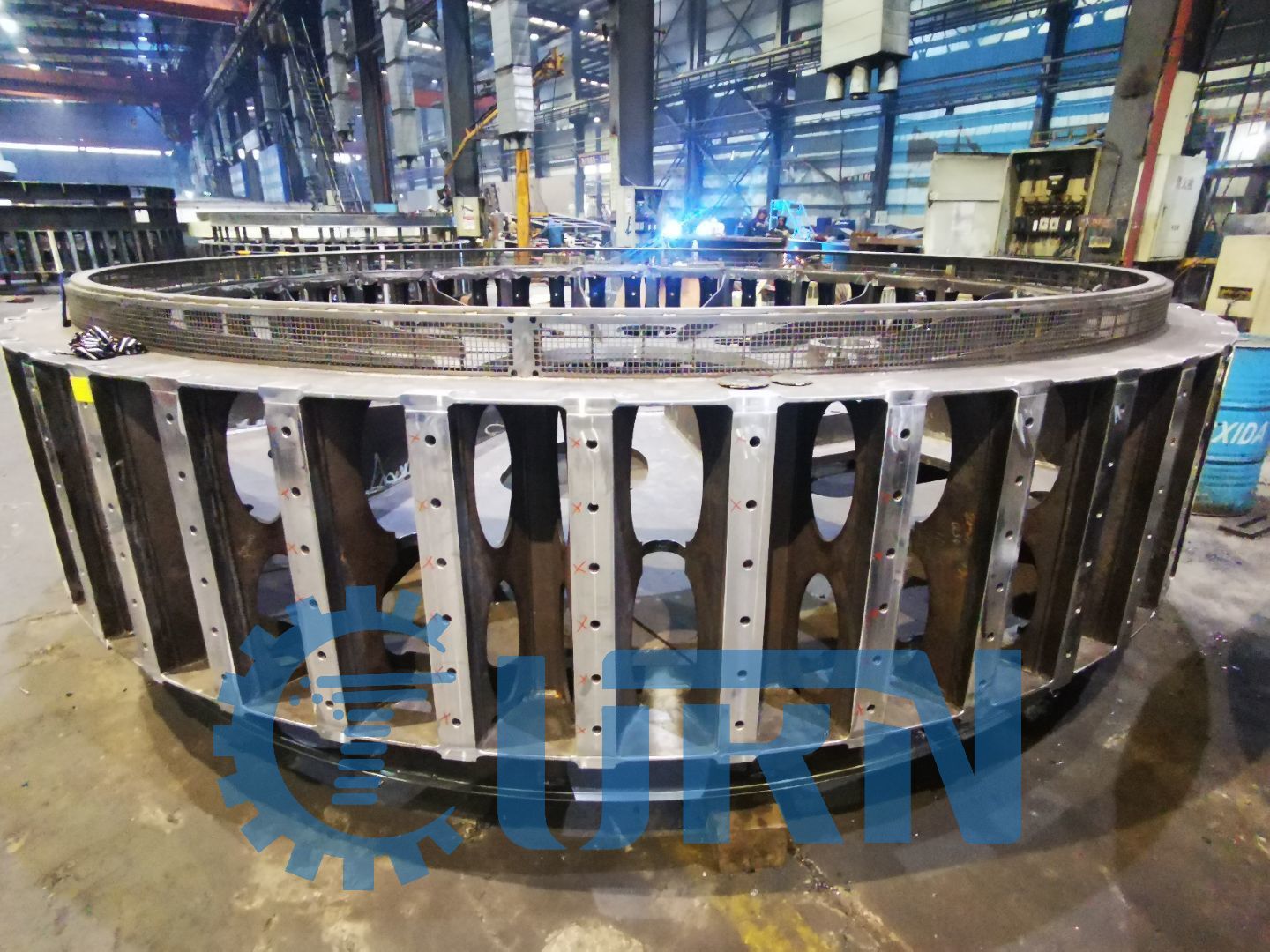

Fuselage (ho kenyeletsoa nko, mapheo, mohatla, joalo-joalo) ho sebetsa.Likarolo tse joalo haholo-holo li na le mehaho e meholo ea foreimi, 'me lisebelisoa ke li-alloys tsa aluminium, li-alloys tsa titanium, joalo-joalo.Mechini ea ho sila fatše ea CNC le e tenang, hape e kenyelletsa mechini e boring le ea ho sila ea CNC, litsi tsa machining tsa CNC gantry, leCNC litsi tse hlano tsa khokahanyo tsa machining tsa gantry.

Ho lokisa lisebelisoa tsa ho theola sefofane.Thepa e hlokahalang bakeng sa lisebelisoa tsa ho theoha sefofaneng li batla li khethehile.Sebaka sa ho lulisa se entsoe ka alloy e matla ea titanium le lisebelisoa tse ling, tseo ho leng thata ho li sebetsana.Sekheo se hloka ho etsoa ka mochine oa khatiso oa lithane tse 10,000, 'me mochine o hloka mochine oa CNC oa ho roala fatše le o borata, litsi tsa machining tsa li-axis tse hlano le lisebelisoa tse ling..

Ntle le moo, indasteri ea tlhahiso ea lisebelisoa tsa ho fehla matla e hloka mechini e meholo e tenang le ea ho sila, e boima Mechini ea CNC e boring le e silang, li-lathe tse kholo tsa CNC, mechine e khethehileng ea ho sila bakeng sa li-grooves tsa blade le mechine ea machining ea CNC ea lehare;indasteri ea tlhahiso ea phetisetso ea matla le lisebelisoa tsa phetoho e hloka lisebelisoa tsa CNC, litsi tsa mochini,Mechini e boring ea CNC, joalo-joalo.

Nako ea poso: May-26-2022