Mochini o Kopantsoeng oa CNC Turn-Milling

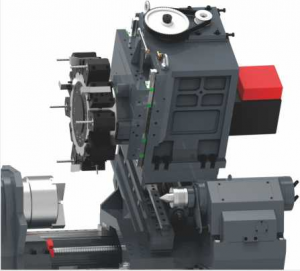

HLAHANG POSITIVEYAXIS

Sebopeho sa Longmen, se thata haholo

Sebopeho se kopantsoeng sa Y axis ke sa ho itšeha ho thata haholo mme ts'ebetso ea eona e betere ho feta axis ea Y.

a. Single Y axis motion heavy cutting e molemo ho feta interpolation Y axis le Y axis e perpendicular to X axis.

b. Phetoho ea li-contour ea sefofane e bonolo ebile e bataletse.

c. E loketseng haholoanyane bakeng sa ho sebetsa ka holim'a metsi le li-contour.

"Positive Y" retelehelang-milling thepa e kopantsoeng e na le melemo e totobetseng ho machining plane milling bapisoa le "interpolation Y" turn-milling e kopantsoeng.Motsamao oa "Positive Y" Y-axis ke perpendicular ho X-axis, e leng ntho e le 'ngoe. -axis movement le "interpolation Y" Y-axis movement ke ho kenyelletsa mola o otlolohileng ka motsamao o le mong oa X-axis le Y-axis, ho bata ha sefofane sa ho sila le papiso ea "positive Y" axis. ho sila ho kopantsoe, "Positive Y" axis turn-milling e kopantsoeng ts'ebetso e hlakile ebile e bataletse.

Sekoti sa bolo e tsitsitseng habeli

Ho sebelisoa li-screws tsa bolo ea boleng bo holimo le litataiso tsa lirolara tse tsoang ho baetsi ba maemo a holimo lefatšeng ka bophara.

Le hoja e le theko e boima, ke lihlahisoa tsa boleng bo phahameng feela tse ka finyellang ho nepahala ho phahameng le nako e telele

bophelo ba tšebeletso bo hlokoang ke bareki.

Li-Servomotors tse kopantsoeng ka kotloloho

Motlakase oa servo o hokahane ka kotloloho le sekoti sa bolo ka ho kopanya tšepe, e leng

e netefatsa hore ha ho na ho senyeha le ho se lumellane le tlas'a meroalo e boima.

Sena se tla ntlafatsa haholo ho nepahala ha maemo, le likhoele le machining a contour

e tla nepahala ho feta.

106M 108M 208M

| Mohlala oa mohlala | Lebitso | Yuniti | 106ME | 108ME | 208ME |

| Tsamaea | Max. Ho fetola Diameter holim'a Bethe | mm | φ600 | φ600 | φ600 |

| Max. Processing Diameter | mm | φ320 | φ300 | φ400 | |

| Max . Ho sebetsa Diameter ho Sesebelisoa sa Sesebelisoa | mm | φ220 | φ220 | φ380 | |

| Max. Bolelele ba Tshebetso | mm | 250 | 250 | 370 | |

| Sebaka pakeng tsa Litsi | mm | 380 | 380 | 600 | |

| Spindle Motor Hydrocylinder Kereke Paramethara | Nko ea Spindle | mofuta | A2-5 | A2-6 | A2-6 |

| Max . Lebelo la Spindle | rpm | 5500 | 4300 | 4200 | |

| Oli Cylinder/ Chuck | lnch | 6” | 8” | 8” | |

| Spindle Bore | mm | φ56 | φ65 | φ65 | |

| Bar Diameter | mm | φ45 | φ52 | φ52 | |

| Direct Drive Spindle Motor Power | kw | 17.5 | 22 | 22 | |

| X/Z/Y Axis Feed Paramethara | X Tsamaea | mm | 180 | 180 | 280 |

| X/Z Linear Guide Tlhaloso | spes | 35/35 Rolara | 35/35 Rolara | 35/35 Rolara | |

| Z Leeto | mm | - | 300 | 600 | |

| X/Z/Y Motlakase oa Motlakase | kw | 1.8/1.8/1.0 | 1.8/1.8/1.0 | 1.8/1.8/1.0 | |

| X/Z//Y Tsela e Potlakileng | m/m | 30/30/10 | 30/30/10 | 20/20/10 | |

| Boemo bo Nepahetseng | mm | ±0.005 | ±0.005 | ±0.005 | |

| Pheta Positioning Ho Nepaha | mm | ±0.003 | ±0.003 | ±0.003 | |

| Parameter ea Turret | Boemo ba Sesebelisoa | likhomphutha | BMT45-12T | BMT45-12T | BMT55-12T |

| Matla a Turret Motor | kw | 2.2/3.7 | 2.2/3.7 | 2.2/3.7 | |

| Square Tool Holder | mm | 20×20 | 20×20 | 20×20 | |

| Round Boring Tool Holder | mm | φ32 | φ32 | φ40 | |

| Haufi le Tool Fetola Nako | mots | 0.15 | 0.15 | 0.15 | |

| Boemo bo Nepahetseng | / | ±2” | ±2” | ±2” | |

| Pheta Positioning Ho Nepaha | / | ±1” | ±1” | ±1” | |

| Mohatla Mekhahlelo | Programmable Hydraulic Tailstock | / | √ | √ | |

| Max . Ho tsamaea ha Tailstock | mm | 360 | 360 | 440 | |

| Tailstock Sleeve Taper Hole | mofuta | MT 5# | MT 5# | MT 5# | |

| Diameter ea Sleeve | mm | / | / | / | |

| Leeto la Leboa | mm | / | / | / | |

| Boholo ba Mechini | Boholo ba Mochini | mm | 2300×1800×1700 | 2300×1800×1700 | 2620×2200×1920 |

| Boima ba Mochini | kg | 3700kg | 3800kg | 5200kg |

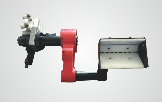

Servo Automatic Bar Feeder

Li-feeders tsa TENOLY li na le moralo o boima le o ikemetseng,

E eketsa tlhahiso haholo mme e nolofatsa ts'ebetso ea ho fetola.

Likarolo Catcher

Motlakase oa mosebetsi o entsoe ka molao-motheo oa ho hokahanya ha mechine, e ka bang kapele

e amanang le sehlahisoa se feliloeng ka mora ho sebetsa.

THK roller linear guide

Tataiso ea mela e na le tumello ea zero, arc cutting, bevel cutting, 'me sebopeho sa bokaholimo se batla se tšoana. E loketse ho sebetsa ka lebelo le phahameng mme e fokotsa haholo matla a ho khanna a hlokahalang bakeng sa mochini oa Linear guide rails sebelisa rolling ho e-na le ho thella, ka tahlehelo e nyane ea likhohlano, karabelo e hlokolosi le ho nepahala ha maemo a holimo. E ka jara moroalo ka holimo, tlase, ho le letšehali le ka ho le letona ka nako e le 'ngoe. Tlas'a mojaro, sebaka sa ho kopana sa pina se ntse se kopana le lintlha tse ngata, 'me ho seha ho sa tsitsang ho ke ke ha fokotseha; Kopano e bonolo le e feto-fetohang le sebopeho se bonolo sa lubricating; litataiso tsa mela li na le ts'ebetso e nyane haholo ebile li tšoarella nako e telele.

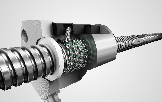

THK Ball Screw

Ho sebelisa sekoti sa bolo se nepahetseng haholo, se kenyang linate esale pele le sekurufu

phekolo ea boikaketsi, ho khutlela morao le ho phahama ha mocheso le

bolelele li tlosoa esale pele, li bonts'a boemo bo botle haholo

le ho pheta-pheta.

Ho khanna ka kotloloho ka servo motor ho fokotsa phoso ea backlash.

Sephaka sa High Precision Motorized Arm bakeng sa Lathe

Hula-down tool setter e nang le mokhoa o phahameng oa ho pheta-pheta E fumaneha ka mefuta e fapaneng ea boholo bo fapaneng ho finyella litlhoko tse fapaneng tsa indasteri E fumaneha ka mefuta e fapaneng ea boholo bo tloaelehileng, hammoho le matsoho a entsoeng ka tšepe a entsoeng ka tšepe a nang le coefficient e tlase ea katoloso.

Sebelisa probe e matla ea zirconia

E nka sebaka se senyenyane sa mochini ha e sa sebelisoe

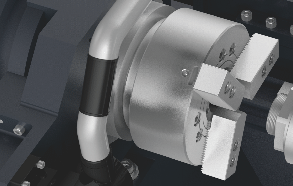

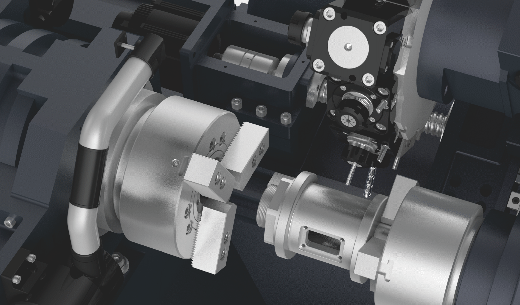

Hydraulic Chuck Workholding

Lathe e na le hydraulic through-hole chuck joalo ka tloaelo. Chuck e ka etsoa ho latela litlhoko tsa bareki, 'me mefuta e fapaneng ea likhetho e tla u fa clamping chuck e loketseng ka ho fetisisa.

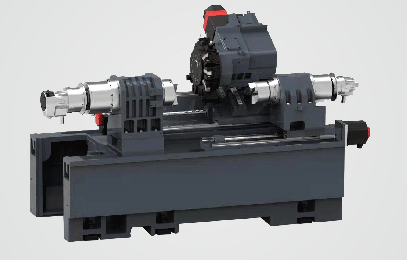

Sekhahla sa bobeli

Lipheletso tse peli tsa workpiece li ka etsoa ka nako e le 'ngoe ka clamping e le' ngoe, e leng ho nolofatsang mosebetsi oa matsoho haholo.