TheMochini o khethehileng oa Valvee sebelisoa haholo ho sebetsana le Valve (Belofo ea Butterfly / Belofo ea Heke / Belofo ea Ball / valve ea lefats'e, joalo-joalo ..), 'mele oa pompo, Likarolo tsa Auto, Likarolo tsa mochini oa kaho jj.

E sebetsa bakeng sa ts'ebetso e fapaneng e fapaneng, joalo ka: Sefahleho sa pheletso, selikalikoe se kantle, moeli o ka pele, lesoba le ka hare, grooving, Screw thread, Bore-hole le Sphere.E ka elelloa ho iketsetsa, ho nepahala ho phahameng, mefuta e mengata e fapaneng le tlhahiso ea bongata.E sebelisoa haholo indastering ea li-valve.

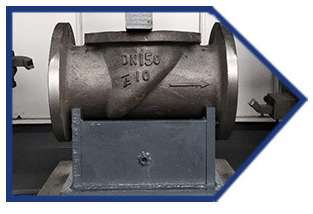

Mabapi leindasteri ea li-valve

Li-valve ke lisebelisoa tsa liphaephe tse sebelisetsoang ho bula le ho koala liphaephe, ho laola phallo, ho lokisa le ho laola liparamente (mocheso, khatello le phallo) ea mokhoa oa ho tsamaisa.Ho ea ka mosebetsi oa eona, e ka aroloa ka valve ea ho koala,ho hlahloba valve, valve e laolang, joalo-joalo.

Belofo ke karolo ea taolo tsamaisong ea ho tsamaisa mokelikeli.E na le mesebetsi ea ho khaola, ho laola, ho kheloha, ho thibela ho phalla ka morao, ho tsitsisa, ho kheloha kapa ho phalla, le ho fokotsa khatello.Li-valve tse sebelisoang mekhoeng ea ho laola metsi, ho tloha ho li-valve tse bonolo ka ho fetisisa tse koalang ho ea ho li-valve tse fapaneng tse sebelisoang mekhoeng ea ho laola ka mokhoa o itekanetseng ka ho fetisisa, li na le mefuta e mengata ea mefuta le litlhaloso.

Li-valve li sebelisoa haholo libakeng tse fapaneng.Haholo-holo petroleum, metallurgy, matla a motlakase, paballo ea metsi, kaho ea litoropo, litima-mollo, mechini, mashala, lijo, joalo-joalo.

Ho fumaneha

Melemo eaMochini o khethehileng oa Valveindastering ea li-valve

√Ho cheka ho amohela mofuta oa li-axis tse ngata, 'me ts'ebetso e ntlafatsoa makhetlo a' maloa.

√Fihlella ho sebetsa ha lihlooho tse peli kapa tse tharo ka nako e le 'ngoe nakong ea ts'ebetso ho hlokomela maemo le katleho e phahameng eaho sebetsa ha valve ea pompo.

√Sistimi e ikhethang e nang le tokelo ea molao ea ho laola lipalo, ts'ebetso e ikemetseng ka botlalo.

Mochini oa rona o khothalelitsoeng oa Valve e khethehileng

Litlhahiso tsa ronadedMochini o khethehileng oa Valve

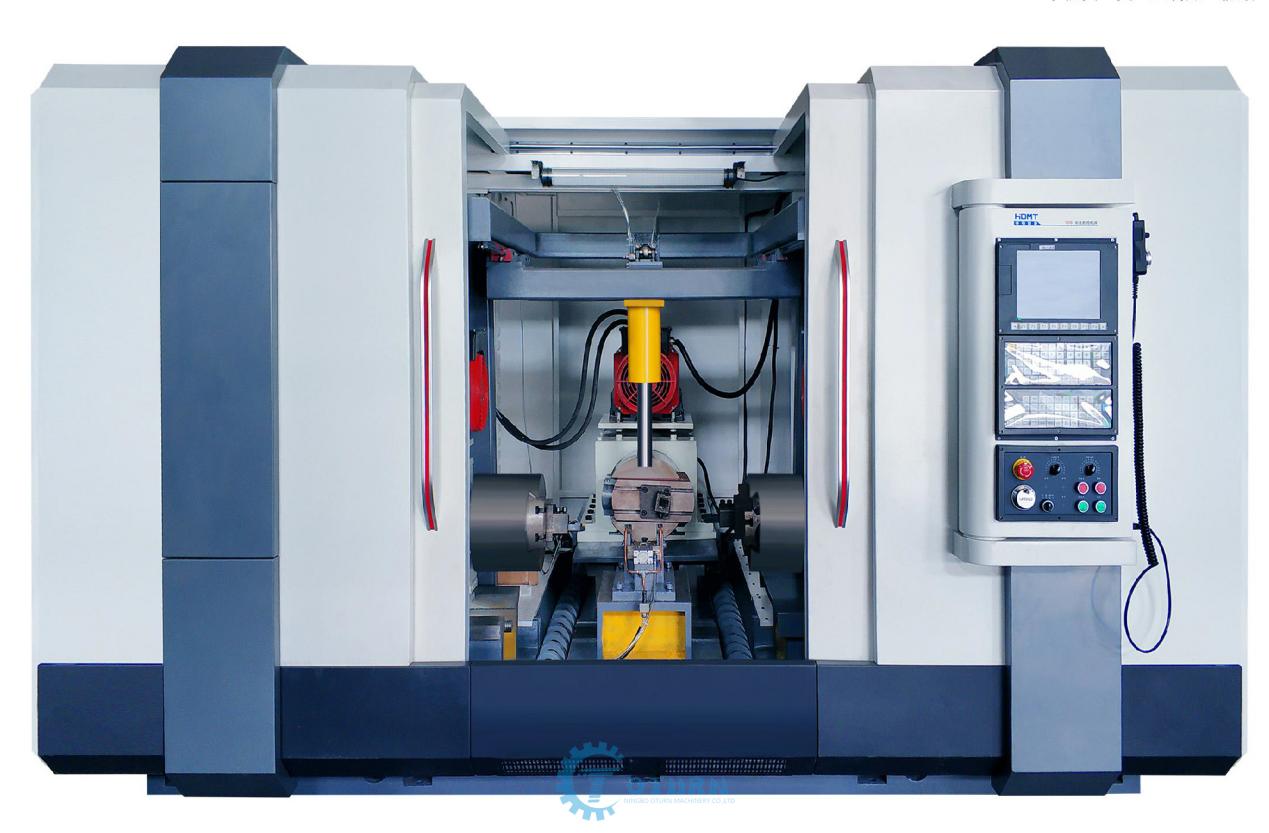

Mochini oa CNC oa lihlooho tse peli

1.'Mele oa mochini

'Mele oa Mochini o entsoe ka tšepe ea boleng bo holimo ea boleng bo holimo, mochini o thata, ho qeta, le liphekolo tse tharo tsa botsofali ho felisa khatello ea maikutlo e setseng.Bokaholimo ba seporo sa tataiso

E amohela pheko ea ho tima maqhubu a molumo o phahameng haholo 'me e sebetsoa ka ho sila seporo sa boleng bo holimo ho netefatsa ho nepahala, ho tiea le botsitso ba sesebelisoa sa mochini.√

2.Mochine o khethehileng oa Valve

Lebokose la Hlooho

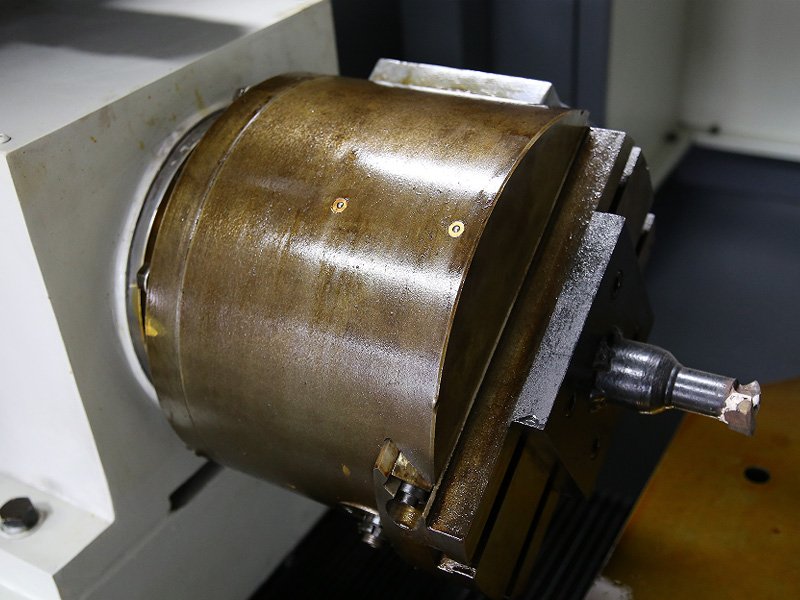

Lebokose la Hlooho le entsoe ka li-castings tsa boleng bo phahameng, 'me lesela le ka sehloohong le entsoe ka 20GrMnTAi, e entsoeng, e tingoe,' me e halefile, e kenngoe ka carburized le ho tima, 'me e eketsoa ke grinder ea cylindrical e nepahetseng ka hare le ka ntle.

Bearing e nka li-rolara tse nang le mela e 'meli ea cylindrical ho netefatsa ho tiea le ho nepahala ha spindle.Shaft e kholo e nka phetoho ea lebelo la mekhahlelo e meraro ka enjene e matla haholo ho fihlela lebelo le tlase

Torque e kholo, e ka jara mojaro o boima oa ho itšeha, ea ntlafatsa ts'ebetso ea ts'ebetso.√

7. Sesebelisoa sa ho lubrication se bohareng

Sistimi ea lubrication e na le sesebelisoa sa lubrication se tsoelang pele sa Nanjing Beqier, se lulang se pompa oli e tlotsang sebakeng sa lubrication ea karolo e 'ngoe le e' ngoe e tsamaeang, e felisa ts'ebetso e tenang ea matsoho.

Ntlafatsa bophelo ba ts'ebeletso ea sesebelisoa sa mochini.√

Mochini oa CNC oa lihlooho tse peli

Serurubelemochine o khethehileng oa valve

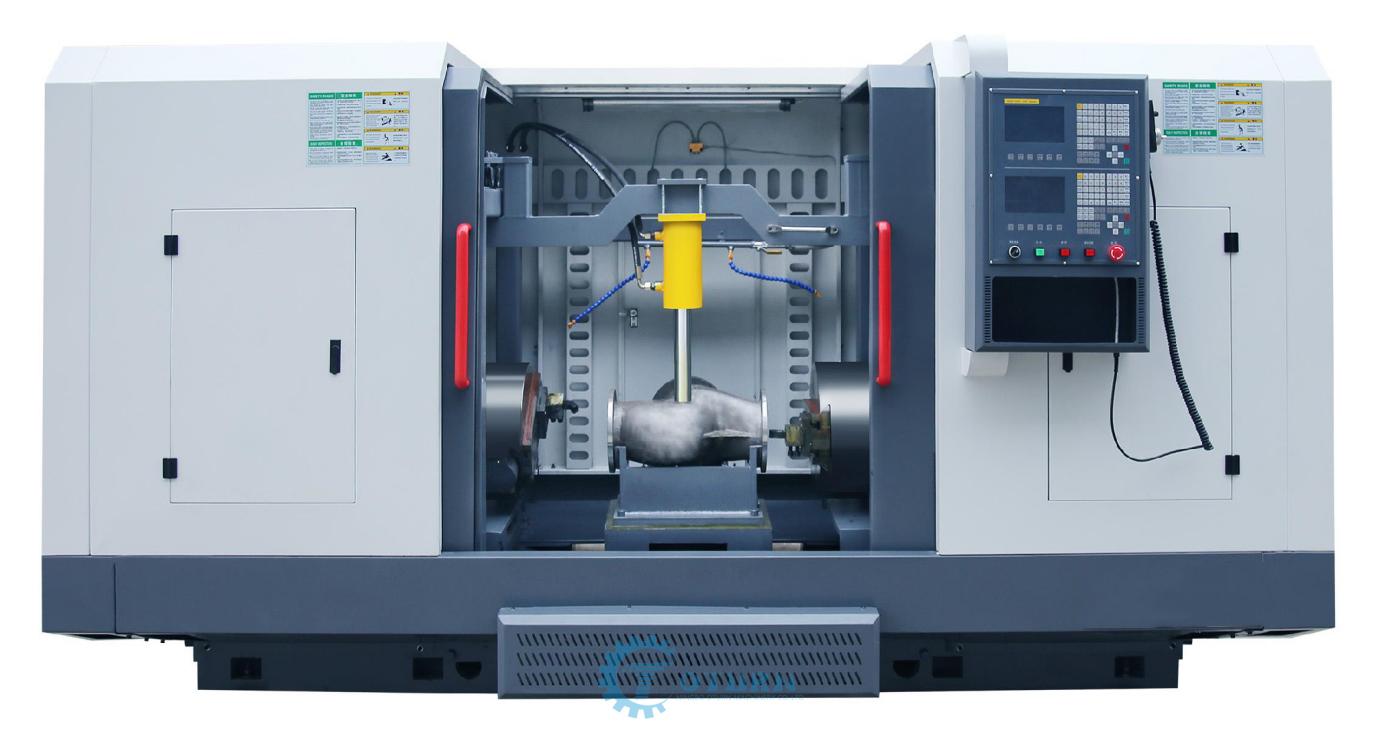

HDCX800 setsi sa machining se kopanyang,serurubele belofoSesebelisoa se khethehileng sa mochini o sebetsang se sebelisoa haholo ho li-valve tsa serurubele le zero

Bakeng sa ho sebetsana le likarolo, mechine ea boenjiniere le likarolo tse ling, sefahleho sa ho qetela, selikalikoe se ka ntle, spigot, lesoba le ka hare, groove, khoele, lesoba la taper le sebopeho sa spherical sa workpiece se ka sebetsoa.

Ho phethola.Ts'ebetso ea ts'ebetso e laoloa ke tsamaiso ea GSK CNC, e khonang ho lemoha ho iketsetsa, ho nepahala ho phahameng, mefuta e mengata, le tlhahiso ea bongata.

tšobotsi e ka sehloohong

1. HDCX800 Special Valve Machine kaofela e laoloa ke tsamaiso ea GSK CNC, e ka lemohuoang ka ho hokahanya ha li-axis tse peli.

Ts'ebetso ea masoba a taper, likhoele le lits'ebetso tsa spherical.Sistimi ea eona ea CNC ea sebetsa, e matla ebile e bonolo ho e sebetsa.

2. Tsela ea tataiso ea li-slide tsa phepelo e entsoe ka tšepe ea boleng bo holimo e bohlooho, e 'nileng ea e-ba tlas'a mekhoa e meraro ea phekolo ea botsofali ka mor'a ho hlaba le ho qeta ho felisa ka botlalo khatello ea kelello e setseng ea ka hare.

Bokaholimo bo amohela kalafo ea ho tima maqhubu a molumo o phahameng haholo mme boima bo fihla ho HRC55.Ho nepahala, ho tiea, le botsitso ba sesebelisoa sa mochini li tiisitsoe ke ho sila ka mokhoa o nepahetseng haholo oa terene.

3. Likarolo tsa phetisetso li khannoa ke li-screws tsa bolo tse nepahetseng le mehato ea ho kenella e sebelisetsoa ho felisa likheo, ho netefatsa hore ho fetisoa le ho sebetsa hantle ha mochine oa mochine.

4. Motlakase oa motlakase o amohela mochine o tsamaisoang ka mekhahlelo e meraro o nang le motlakase o matla haholo ho finyella lebelo le tlaase le torque e phahameng, e ka mamella meroalo e boima ea ho itšeha, le ho ntlafatsa ts'ebetso ea ts'ebetso.

5. Lisebelisoa li sebelisa hydraulic automatic clamping ho ntlafatsa katleho le ho fokotsa matla a mosebetsi oa motho.

6. HDCX800 Special Valve Machine,serurubele valve mochine o khethehileng oa ho sebetsasesebelisoa se amohela lubrication e bohareng ho netefatsa hore karolo e 'ngoe le e' ngoe e tsamaeang e tlositsoe ka botlalo le ho ntlafatsa sesebelisoa sa mochini.

Mochini o khethehileng oa Valve Sebopeho

Hlooho ea Matla

'Mele oa hlooho ea hlooho ea matla o entsoe ka li-castings tsa boleng bo phahameng,' me sekoti se seholo se entsoe ka thepa ea 20GrMnTAi, e sebetsoang ka ho forging, quenching, le tempering, carburizing le quenching, le li-grinders tsa cylindrical tse ka hare le tsa ka ntle tse nepahetseng ka ho fetisisa.

Bearing e nka NN30 letoto la li-roller tsa cylindrical tse nang le mela e 'meli e nepahetseng haholo ho netefatsa ho tiea le ho nepahala ha spindle.

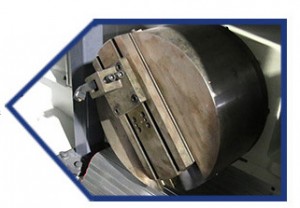

Tafole ea mosebetsi

Sebaka sa ho sebetsa ke benche e khethehileng ea mosebetsi e entsoeng ka ho khetheha ho latela likarolo tse sebetsitsoeng.Li-blocks le lithapo tsa ho beha maemo kaofela lia tingoa ho netefatsa boemo bo ts'epahalang ba workpiece.

Workpiece clamping e amohela clamping ea matsoho ho ntlafatsa ts'ebetso e sebetsang hantle le ho fokotsa matla a mosebetsi oa motho.'Me tafole ea ho sebetsa e ka fetisoa ka likhato tse 180, ho koala ka nako e le' ngoe, nako e le 'ngoe Qetella lits'ebetso tsohle.

Makasine ea sesebelisoa sa ho fetola sesebelisoa se ikemetseng

Makasine ea sesebelisoa sa ho fetola lisebelisoa tsa CNC ka ho feletseng, e ka tšoarang lisebelisoa tsa 16, lisebelisoa tsa 20, lisebelisoa tsa 24, joalo-joalo, tse laoloang ka mokhoa o ikemetseng ke tsamaiso, ka lebelo la ho fetola lisebelisoa ka potlako le ho nepahala ho nepahetseng.

- Hlooho ea matla

Hlooho ea matla e nka sebopeho se ikhethileng sa motor + screw screw, se nang le litšobotsi tsa ho nepahala ho phahameng, ho tiea ho hoholo le bophelo bo bolelele.

- Lisebelisoa

-

The tooling ke lisebelisoa tse khethehileng tse entsoeng ka ho khetheha ho latela likarolo tse lokelang ho sebetsoa.Li-blocks le lithapo tsa ho beha maemo kaofela lia tingoa ho netefatsa boemo bo ts'epahalang ba workpiece.Sebaka sa ho sebetsa se hatelloa ke hydraulic clamping, e ntlafatsang ts'ebetso ea ts'ebetso le ho fokotsa matla a basebetsi.

- Khabinete ea motlakase

Khabinete ea motlakase e nka mofuta o ikemetseng o koetsoeng, o nang le sistimi e hahelletsoeng ka har'a sesebelisoa, mochini o fetolelang khafetsa le likarolo tsa motlakase oa taolo ea boema-fofane, 'me o na le lisebelisoa tse futhumatsang moea ho netefatsa hore likarolo tsa motlakase tsa sesebelisoa sa mochini li sebetsa ka mokhoa o tloaelehileng ebile ha li kene leroleng.

- CNC Cho laola Sistimi

E na le mesebetsi ea thekenoloji ea ho laola mechine e mengata, mechine e mehlano ea li-axis, lebelo le phahameng le ho nepahala ho phahameng, ho fetola le ho sila, taolo ea synchronous le taolo e meng e phahameng ea CNC.

Khetho ea lisebelisoa:

Taolo ea CNC

taolo ya ho phodisa

Automatic chip conveyor

Tšhireletso (half-t-half/) /feela

Bakeng sa mefuta e fapaneng ea li-valve, mekhoa e fapaneng e sebetsanoa.Mohlala, mesebetsi ea tlhahiso le litokisetso tse fapaneng tsa tekheniki li hloka ho etsoa pele ho sebetsoa.Baenjiniere ba hloka ho etsa litokisetso tse nepahetseng ho latela moralo oa sehlahisoa ka bosona le lisebelisoa tse khethehileng tsa tlhahiso ea lifofane tsa Huadian valve.Likarolo tse se nang letho tsa li-valve li ka etsoa ka ho lahla lehlabathe, ho lahla ka mokhoa o nepahetseng kapa ho lahla boka ha motsu ha ho etsoa.Bakeng sa lits'ebetso tsa forging kapa welding, hoa hlokahala ho rala ho latela maemo a se nang letho.

Themekhoa ea ho lokisa li-valveli rarahane, 'me boleng bo eketsehileng ba sehlahisoa bo tlaase.Melemo ea ho sebelisa kakaretso-morero kapaLisebelisoa tsa mochini oa CNCha e kgone ho bonahatswa.Ho sebetsa ka ho feletseng ha valve ho bile ho hloka motsoako oa mechine e mengata ho finyella phello ea ts'ebetso.Nako le nako ha u fetola boholo kapa mefuta e fapa-fapaneng, u lokela ho fetola sesebelisoa sa mochine, ebe u fetisetsa ts'ebetso e phethiloeng ho tloha ts'ebetsong e fetileng ho ea ho sesebelisoa sa mochine se tsamaisanang le ts'ebetso e latelang.Sena ha se eke feela litšenyehelo tsa tlhahiso, empa hape se senya nako e ngata ea litšenyehelo.Ka kakaretso, li-workpieces tse hlokang ho nepahala ho phahameng, ka lebaka la liphetoho tse ngata tsa clamping, li eketsa phoso e nepahetseng ea workpiece.Kahoo melemo easefofane sa valvelia iponahatsa.

Ka mohlala, bakeng sali-valve tsa heke, ho fetoha ha li-flange tse mahlakoreng a mararo ho ka etsoa ka mochine o le mong.Hona joale, mochine o khethehileng oa li-valve tsa HDMT o ka sebetsana ka nako e le 'ngoe mahlakore a mabeli kapa a mararo a valve flange ka nako e le' ngoe, e leng e bonolo le e sebetsang hantle, ha tlhahiso ea setso Ho ka sebetsoa ka nako e le 'ngoe feela, e leng nako e ngata. le mosebetsi o boima.Ka mokhoa o ts'oanang, ho phunya ha flange ka mahlakoreng a mararo kapa a mabeli a valve ho boetse ho itšetlehile ka molao-motheo o tšoanang, o sa ntlafatseng feela katleho, empa hape o fokotsa mamello ea boemo ba lesoba.

Ts'ebetso eamochine o khethehileng oa valvee boetse e bonolo haholo, mefuta eohle e hlokometse moralo o ikemetseng, e hloka feela ho kenya litekanyo.Sena se fokotsa haholo ts'ebetso ea matsoho, se fokotsa litšenyehelo tsa basebetsi, 'me se boloka nako le boiteko.Haeba ho na le moroalo o mongata kapa bothata bo bong bo etsahala nakong ea ts'ebetso ea tlhahiso, mochini o tla fana ka alamo hang-hang kapa o koalehe ka bohona, e le ho qoba tšenyo ea mochini haholo.

Ka mor'a hore sefofane sa valve se phethoe, opareitara e lokela ho tima motlakase o amanang le eona, ho etsa mosebetsi o motle oa ho hloekisa, le ho sebelisa mafura a litsebi ho lokisa le ho boloka sefofane sa valve.Ho na le lintho tse ngata tse lokelang ho lefshoa nakong ea ts'ebetso ea mochine o khethehileng oa valve.Mochine o khethehileng oa li-valve ha o khone ho etsa mesebetsi e kang ho lokisa lisebelisoa, ho hlahloba le ho tlosoa nakong ea ts'ebetso.Nakong ea ts'ebetso eohle ea mochini o khethehileng oa li-valve, basebetsi ba amehang le ba sebetsang ha baa lokela ho tlohela mesebetsi ea bona, 'me ba tlameha ho etsa mosebetsi o motle oa tlhokomelo e nepahetseng.Lisebelisoa tse kang li-workpieces, fixtures, le lithipa li tlameha ho tiisoa ka thata, ho seng joalo mathata a mang ka motsamao oa workpiece a tla ba teng.Ho sebetsa hampe ho ka baka likotsi tse sa hlokahaleng.Haeba thipa e robehile kapa e robehile, e hloka ho nkeloa sebaka ka nako.Ts'ebetsong ea ts'ebetso e tloaelehileng, re ke ke ra ama ka ho toba holim'a mosebetsi oa matsoho ka matsoho a rona, leha e le hore re ka tlosa ka ho toba lintho tse kotsi tse kang ho itšeha ka matsoho.Sena se ke ke sa utloisa matsoho a rona feela bohloko, empa hape se tla etsa hore lithapo tsa tšepe li fofe.Kotsi mahlong.Nakong ea mosebetsi oasefofane se khethehileng sa valve, o lokela ho apara liofarolo tse tsamaellanang, a roale kepisi ea mosebetsi, 'me u be le bonnete ba hore o kenya moriri oa hau ka har'a kepisi ea mosebetsi.Ha u kenya le ho laolla li-workpieces tse kholo, leka ho sebelisa lisebelisoa tsa ho phahamisa, e le hore ts'ebetso eohle e ka phelisana ka botsebi, 'me ts'ebetso ea ts'ireletso e tla ba e phahameng.

Nako ea poso: Sep-22-2021