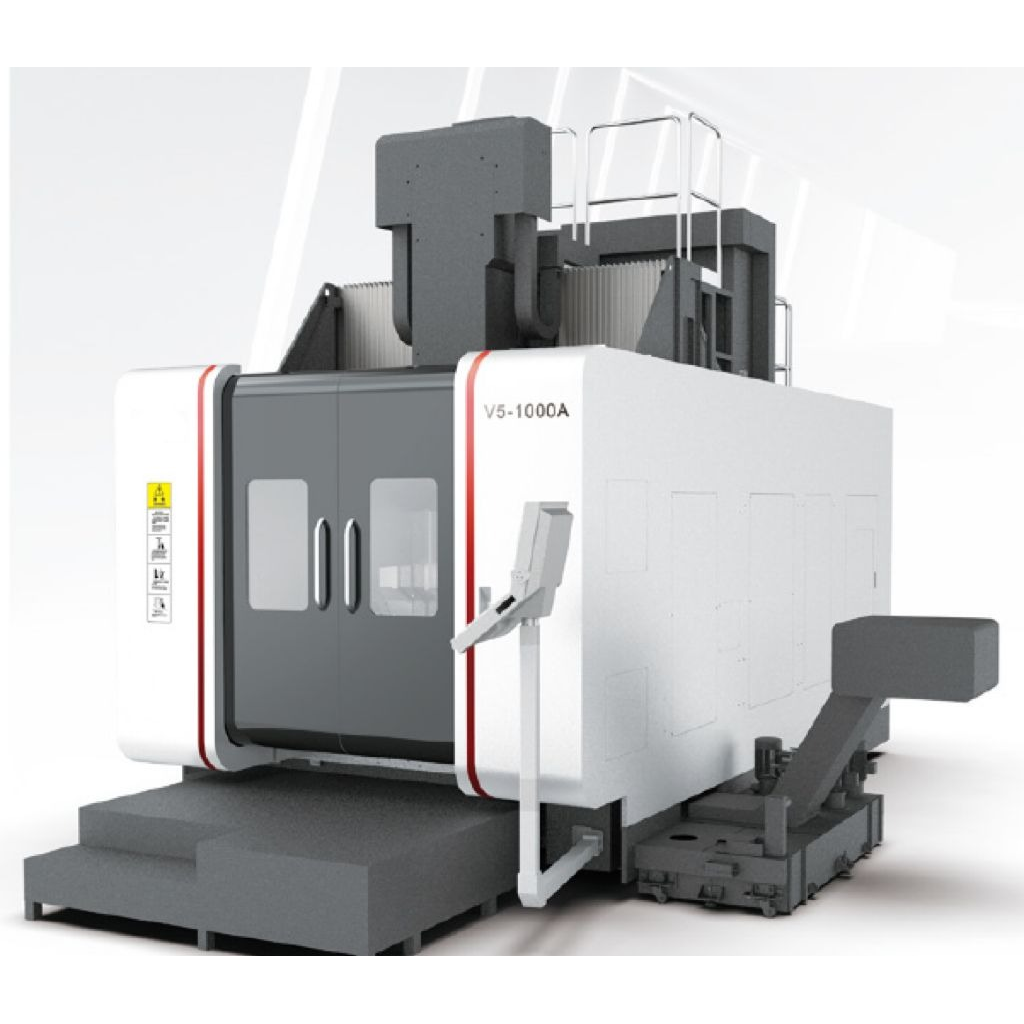

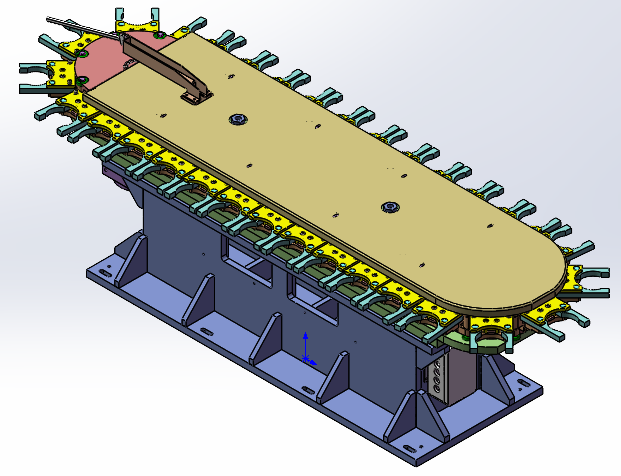

Setsi sa machining sa V5-1000A 5-axis

Setsi sa Machining sa Axis tse hlano

Setsi sa machining sa V5-1000A se nang le li-axis tse hlano se nka mohaho o tsitsitseng o koetsoeng oa gantry 'me o na le mochini o tloaelehileng oa spindle oa motlakase, mochine oa ho fetola CNC oa li-axis tse peli le makasine ea lisebelisoa tsa servo tse otlolohileng. E khona ho tseba ho lokisa likarolo tse rarahaneng ka lebelo le holimo, ka nepo, le ka bokhabane. E sebelisoa haholo ho Tlhahiso e ncha ea likoloi tsa matla, li-blisks tsa bohlokoa tsa sefofane, li-impellers tsa turbine tsa mouoane, hlobo le lihlahisoa tse ling.

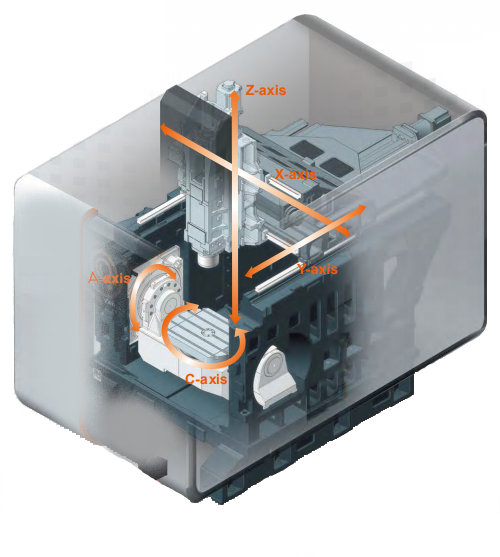

1. Kakaretso ea moralo oa mochine

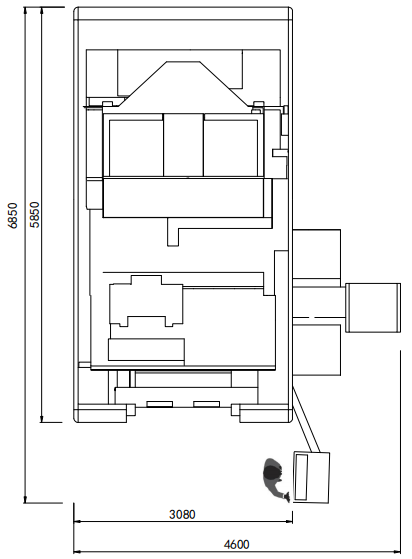

Setsi sa machining sa V5-1000A se nka sebopeho se tsitsitseng sa gantry, kholomo e tsitsitsoe botlaaseng, leballo le tsamaea ka nako e telele ho theosa le kholomo (Y directional), poleiti ea slide e tsamaea ka thoko ho lebaleng (karolo ea X), le hlooho ea hlooho e tsamaea e theohile ho bapa le poleiti ea li-slide (kaho ea Z) . Sebaka sa mosebetsi se nka sebopeho sa cradle se iketselitseng sona, 'me matšoao a fapaneng a ts'ebetso a fihlile boemong bo phahameng ba machaba.

2. Mokhoa oa ho fepa

Lilepe tsa X, Y, Z li sebelisa ho tiea ho hoholo, litataiso tsa mela e nepahetseng e phahameng le likurufu tsa bolo tse sebetsang hantle haholo, tse nang le khohlano e tlase e matla le e tsitsitseng, kutlo e phahameng, ho thothomela ho tlase ka lebelo le holimo, ha ho ho thella ka lebelo le tlase, boemo bo holimo. ho nepahala, le ts'ebetso e ntle ea servo drive.

X, Y, Z axis servo motors li hokahane le li-screw tse nepahetseng tsa bolo ka li-reducers tse nepahetseng, tse nang le phepo e bonolo, maemo a nepahetseng le phetiso e nepahetseng haholo.

Enjene ea servo ea Z-axis e na le ts'ebetso ea brake. Tabeng ea ho felloa ke matla, e khona ho tšoara brake ka bo eona ho tšoara shaft ea motor ka thata hore e se ke ea potoloha, e leng se phethang karolo ea tšireletso.

3. Spindle ea motlakase

The spindle motorized BT50 motorized spindle (HSKA100 motorized spindle ke boikhethelo), 'me qetello e na le motsoako oa lesale ho pholisa sesebelisoa. E na le melemo ea lebelo le phahameng, ho nepahala ho phahameng, karabelo e matla e phahameng, joalo-joalo, 'me e khona ho hlokomela taolo ea lebelo le se nang mohato, e hahiloeng ka har'a encoder e nepahetseng haholo, e ka fihlella ho emisa ho nepahetseng le ho tlanya ka thata.

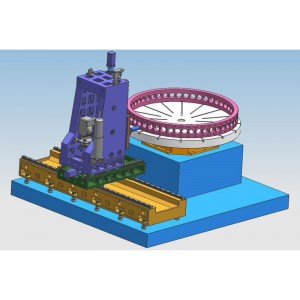

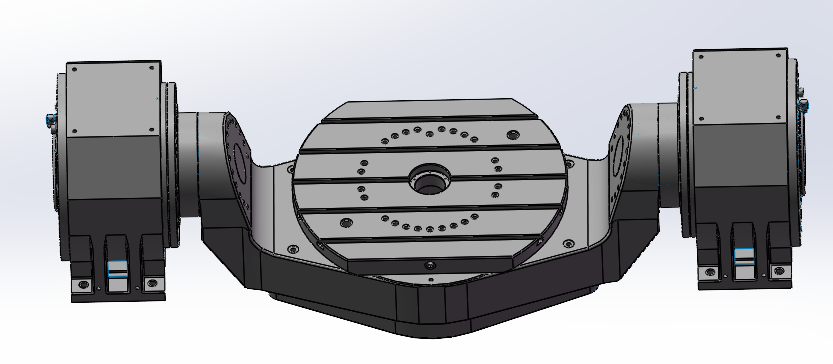

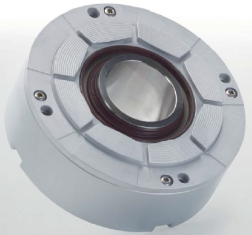

4. Turntable

Mohaho o ikemetseng oa "dual-axis direct-drive cradle turntable" o na le encoder ea boemo bo holimo 'me e pholile ka sehatsetsi sa metsi ka mocheso o sa fetoheng. E na le melemo ea ho tiea ho hoholo, ho nepahala ho phahameng, le karabelo e matla e phahameng. The worktable e nka 5-18mm radial T-slots, mme mojaro o lumelletsoeng ke 2000kg (e abuoa ka ho lekana)

5. Makasine ea lisebelisoa

Makasine ea sesebelisoa e amohela makasine ea BT50 e otlolohileng ea ketane ea servo, e ka amohelang lisebelisoa tse 30.

6. Sistimi e koetsoeng ka botlalo ea loop

X, Y, Z lilepe tse melang li na le HEIDENHAIN LC195S 'musi oa boleng bo felletseng ba grating; Litafole tsa rotary tsa A le C li na le HEIDENHAIN RCN2310 li-angle encoder tsa boleng bo felletseng ho fumana maikutlo a koetsoeng a lilepe tse 5 tsa phepelo, ho netefatsa hore mochini o na le ho nepahala ho phahameng le Poko e nepahetseng haholo.

7. Mohatsela le tsamaiso ea moea

E na le pompo e kholo ea pholiso ea phallo le tanka ea metsi ho fana ka pholiso e lekaneng bakeng sa lisebelisoa le lisebelisoa. Sefahleho sa hlooho sa hlooho se na le li-nozzles tse pholileng, tse ka laoloang ke M code kapa control panel.

E na le mochine o pholileng oa metsi bakeng sa ho phomola mocheso o sa khaotseng, ho etsa bonnete ba hore spindle ea motlakase le turntable ea drive e tobileng li maemong a matle a ho sebetsa 'me li ka sebetsa ka katleho nako e telele.

Sistimi ea moea e amohela likarolo tsa moea bakeng sa ho sefa, 'me e hlokomela mesebetsi ea ho hloekisa le ho phethola lesoba la seluloana, ho sireletsa tiiso ea moea ea mokokotlo, le ho butsoela le ho hloekisa rulara.

8. Sistimi ea lubrication e bohareng

Boloko ba selaete sa seporo sa tataiso le nate ea screw screw kaofela li tlositsoe ka mafura a tšesaane, 'me lubrication e fanoa khafetsa le ka bongata ho netefatsa ho nepahala le botsitso ba screw ea bolo le seporo sa tataiso.

9. Oli le khase lubrication tsamaiso

Seluloana sa motlakase se na le sesebelisoa sa ho tlotsa oli le khase se tsoang kantle ho naha, se khonang ho tlotsa le ho pholisa seluloana. Sensor e ka fana ka alamo e sa tloaelehang ea lubrication, e ka netefatsang hore spindle e ka sebetsa ka mokhoa o tsitsitseng ka lebelo le phahameng nako e telele.

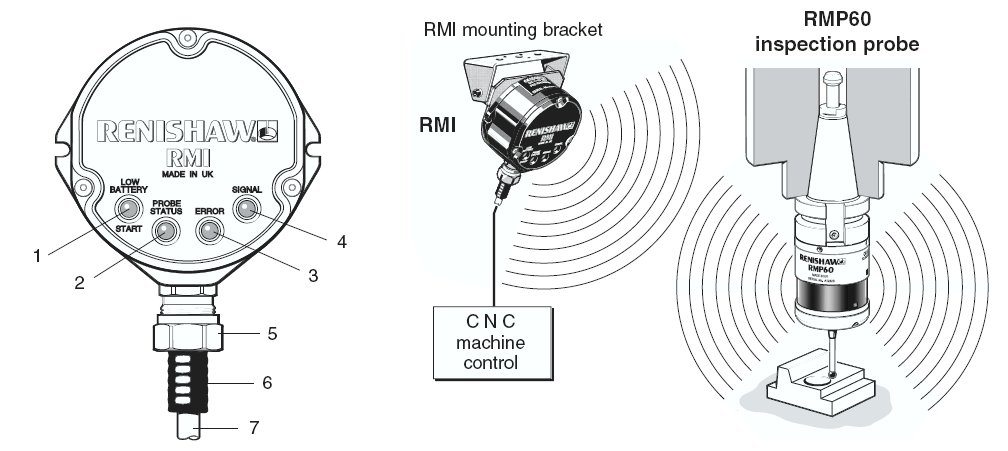

10. Mokhoa oa ho lekanya oa workpiece

Mochini o na le probe ea radio ea Renishaw RMP60, e sebelisoang hammoho le moamoheli oa RMI, frequency ea ho sebetsa ke 2400 MHz ho 2483.5 MHz, tekanyo ea ho pheta-pheta ka tsela e le 'ngoe e ka tlase kapa e lekana le 1um (480mm/min) lebelo la tekanyo, o sebelisa 50mm pene), mme mocheso o sebetsang o sebetsang ke 5°C ho isa ho 55°C.

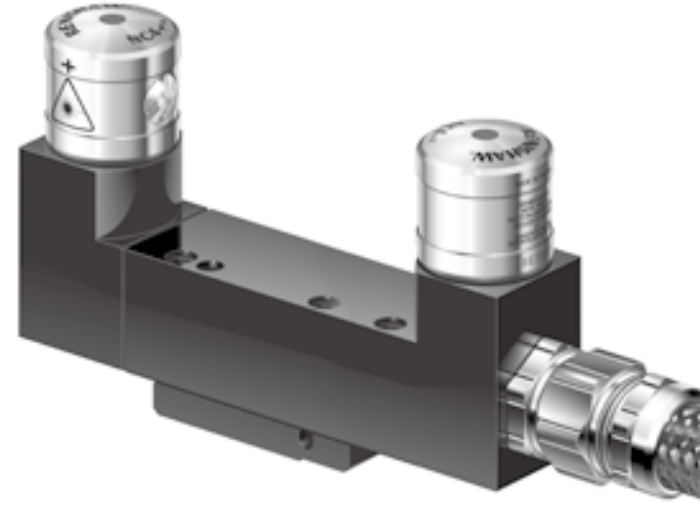

11. Mokhoa oa ho lekanya lisebelisoa

Mochini o na le Renishaw NC4 laser tool setter, tekanyo ea ho pheta-pheta ke ± 0.1um, 'me mocheso o sebetsang ke 5 ° C ho isa ho 50 ° C.

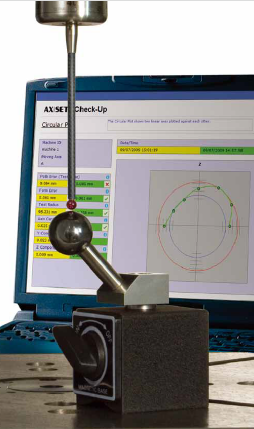

12. Mosebetsi oa ho lekanya ho nepahala ha li-axis tse hlano

Mochini o na le lisebelisoa tsa Renishaw's AxiSet Check-Up Rotary Axis Line Checker kit, e kopantsoeng le sistimi ea tekanyo ea li-workpiece RMP60, e nolofalletsa basebelisi ba mochini ho lekola boemo ba lilepe tsa rotary kapele le ka nepo le ho tseba mathata a bakoang ke liphetoho tsa mocheso le mongobo, ho thulana ha mochini kapa. ho qhoma. mathata, e khona ho lokisa kapele le ho fumana licheke tsa ts'ebetso, ho beha boemo le ho beha leihlo hore na mechini e rarahaneng e fetoha joang ha nako e ntse e feta.

13. tšireletso ea mochine

Mochini o nka sekoaelo sa ts'ireletso se kentsoeng ka botlalo se fihlelang litekanyetso tsa polokeho ho thibela ho phatloha ha pholileng le lichipisi, ho netefatsa ts'ebetso e bolokehileng, le ho ba le ponahalo e ntle. Tsela ea X ea mochine e na le sekoahelo se sirelelitsoeng se sirelelitsoeng, se ka sireletsang seporo sa tataiso ka katleho le sekoti sa bolo.

14. maemo a ho sebetsa mochine

(1) Phepelo ea matla: 380V±10% 50HZ±1HZ ea mekhahlelo e meraro ea hona joale

(2) Mocheso oa tikoloho: 5℃-40℃

(3) Mocheso o motle ka ho fetisisa: 20℃±2℃

(4) Mongobo o amanang: 20-75%

(5) Khatello ea mohloli oa moea: 6±1 bar

(6) Phallo ea mohloli oa moea: 500 L / min

15. Kenyelletso ea mosebetsi oa tsamaiso ea CNC

Siemens 840Dsl.730 CNC tsamaiso ea tsamaiso

| Ntho

| Lebitso

| Litlhaloso

|

| Mesebetsi ea tsamaiso | Bonyane bo lekanang le ho otla ha pelo | Linear axis 0.001 mm, rotary axis 0.001° |

| Sekhahla sa lijo ka motsotso / phetoho | ||

| Fepa le ho haola ka potlako | ||

| Feedrate override 0~120% | ||

| Moeli oa lebelo la spindle | ||

| Ho itšeha ka lebelo ho sa feleng | ||

| Ho shebella ka spindle | ||

| Spindle e fetang 50 ~ 120% | ||

| Pontšo ea lebelo la spindle | ||

| MOTSAMAI | Lemoha phetoho e hokahanyang ea sistimi le machining a bevel | |

| Phetoho ea tsamaiso ea tekanyo e tobileng/e sa tobang | ||

| Tshebetso ya ho sheba pele kapa tshebetso ya ho sheba pele | ||

| Puseletso ea phoso ea sekorufu sa lead | ||

| Matšeliso a Phoso ea Tsamaiso ea Tekanyo | ||

| Matšeliso a Phoso ea Quadrant | ||

| Puseletso ya morao | ||

| Tsamaiso ea lisebelisoa | ||

| Sebopeho sa Hardware | Palo ea lilepe tsa taolo | X, Y, Z, A, C li-axis tse hlano tsa coordinate le axis e le 'ngoe e kholo |

| Taolo ea nako e le 'ngoe ea palo ea lilepe | X, Y, Z, A, C khokahano ea li-axis tse hlano | |

| lebitso la axis | X, Y, Z, A, C, SP | |

| hlokomela | Pontšo ea LCD ea 15" ea mebala, e bonts'a mongolo ka Sechaena/Sekhooa | |

| Phanele ea ts'ebetso | OP015 tshebetso e feletseng CNC keyboard | |

| sehokelo sa puisano sa mochini oa motho | TCU ea tlhophiso e tloaelehileng | |

| Phanele ea taolo ea mochini | SINUMERIK MCP 483C PN control panel, 50 mechanical keys with LED, with PROFINET, Industrial Ethernet interface | |

| Karolo ea ts'ebetso ea letsoho | ||

| Sehokelo se tloaelehileng sa keyboard | ||

| Sehokelo sa Ethernet | E kopantsoe ho NCU (mosebetsi oa marang-rang o bulehileng oa workshop) | |

| Boema-kepe ba USB | 3 x 0.5 USB e kopantsoeng ho TCU | |

| Lenaneo la PLC | PLC317-3PN/DP | |

| Mosebetsi oa ho fetolela | Fepa khefutsa | |

| ho poma khoele | ||

| Ho poma ka nako e le nngwe | ||

| Phetolelo ea mela e meraro e hokahanyang | ||

| Ho kenyeletsoa ka selika-likoe ho kopantseng tse peli | ||

| Tlhaloso ea Helical | ||

| Tlanya/ Ho tlanya ka thata | ||

| mananeo | Ho chamfer/ ho pota ka ho feteletseng | |

| mohlophisi oa lenaneo | Latela maemo a DIN66025, a nang le likarolo tsa maemo a holimo a mananeo a puo | |

| Lenaneo le felletseng kapa le ntseng le eketseha | ||

| Mosebelisi e feto-fetohang, e hlophisitsoe | ||

| Lenaneo le qhoma le makala | ||

| lenaneo la macro | ||

| Kopanya phetolelo ea sistimi le ho potoloha | ||

| Mananeo le machining ka nako e le 'ngoe | ||

| Taelo ea lenaneo ho khutlela sebakeng sa litšupiso | ||

| Mananeo a contour le lenaneo la potoloho ea makotikoting | ||

| Ho etsa seipone le ho eketsa | ||

| khetho ea sefofane | ||

| Sistimi ea ho hokahanya ea workpiece | ||

| Ho cheka le ho sila ka makotikoting potoloho | ||

| Zero offset | ||

| thibela ho batla | ||

| Patlo ea nomoro ea lenaneo | ||

| Tokiso e ka morao | ||

| tshireletso ya lenaneo | ||

| Khetha lenaneo ka directory | ||

| Mesebetsi ea Arithmetic le trigonometric | ||

| Papiso le ts'ebetso e utloahalang | ||

| Sephutheloana sa software sa machining sa li-axis tse hlano | Phetoho ea li-axis tse hlano; puseletso ea lisebelisoa tsa li-axis tse hlano; mosebetsi oa ho potoloha ho potoloha setsi sa lisebelisoa (RTCP) | |

| Ts'ireletso ea ts'ireletso ea ts'ireletso | Meeli ea sebaka sa machining e ka etsoang | |

| Mosebetsi oa teko ea lenaneo | ||

| setopong sa tshohanyetso | ||

| Tlhokomelo ea moeli oa software | ||

| Tlhokomelo ea li-contour | ||

| Ho lemoha ho thulana ha contour | ||

| Tlhokomelo e tsitsitseng | ||

| Tlhokomelo ea sebaka | ||

| ho beha leihlo lebelo | ||

| Lithibelo tsa sebaka sa tšebetso | ||

| moeli oa torque | ||

| Mesebetsi ea ts'ireletso litekanyo tsa litekanyo tsa oache, ho futhumala ho feteletseng, betri, voltage, memori, li-switches tse fokolang, ho lekola fan. | ||

| Mokhoa oa ts'ebetso | TS'OANELO | |

| JOG (manual) phetoho | ||

| Ts'ebetso ea mabili a letsoho | ||

| Ho kenya data ka letsoho ho MDA | ||

| Tlhahlobo ea NC le PLC e nang le ponts'o ea mongolo, sesebelisoa sa skrine | ||

| tshebetso le pontsho | Pontsho ya tshebetso ya ho itlhahloba | Ho kenyeletsoa mokhoa oa REF, mokhoa oa ho eketsa (x1, x10, x100) |

| Pontšo ea sebaka sa hajoale | ||

| Pontšo ea setšoantšo | ||

| pontsho ya lenaneo | ||

| pontsho ya phoso ya lenaneo | ||

| Pontšo ea phoso ea ts'ebetso | ||

| Pontšo ea sebele ea lebelo | ||

| Sechaena le Senyesemane se bonts'a menu | ||

| Pontšo ea lintlha tsa alamo | ||

| Lisete tse ngata tsa litaelo tsa M-code | ||

| Ts'ehetsa phetiso ea data ea bese ea PROFINET | ||

| puisano ya data | Boema-kepe ba USB | Lintlha tsa NC, data ea PLC le mananeo a tšehetsoa ho disk ea U bakeng sa lintlha tsa ho kenya le tse hlahisoang |

| Phetiso ea data ea Ethernet | Ka sebopeho sa Ethernet |

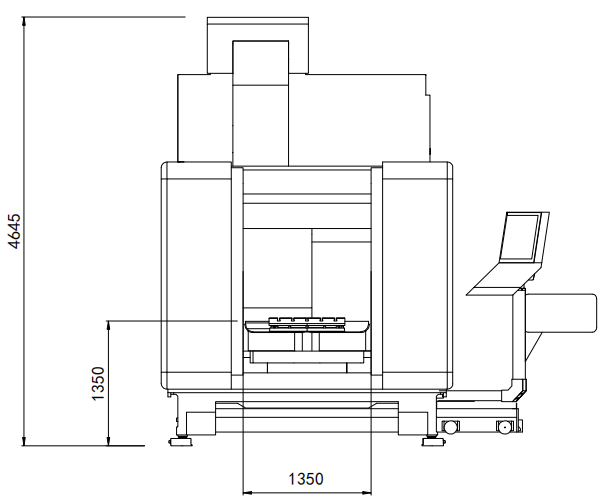

Parameter e kholo

| Ntho | Litlhaloso | Yuniti | |||

| benche ea mosebetsi

| boholo ba deske e sebetsang | φ1000×800 | mm | ||

| moroalo o dumelletsweng | 2000 | kg | |||

| T-slot boholo | 5×18 | 个×mm | |||

| ho sebetsa bophara

| X axis | 1150 | mm | ||

| Y axis | 1300 | mm | |||

| Z axis | 900 | mm | |||

| A-axis | -150+130 | ° | |||

| C axis | 360 | ° | |||

| Sebaka ho tloha sefahlehong sa spindle ho ea tafoleng ea mosebetsi | Max | 1080 | mm | ||

| Min | 180 | mm | |||

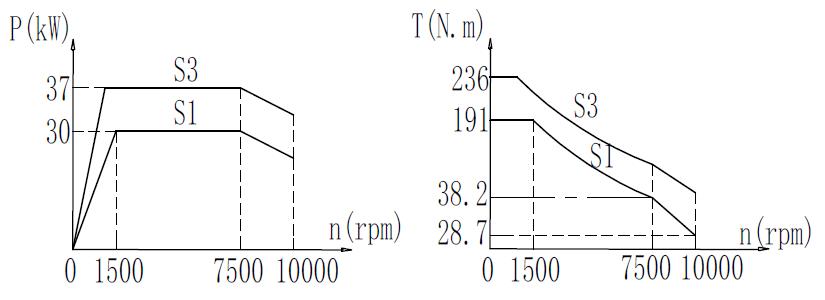

| Spindle

| Mokoti oa khoele | BT50 | |||

| Lebelo le lekantsoeng | 1500 | r/mets | |||

| lebelo le phahameng | 10000 | ||||

| Torque e hlahisoang ke S1/S6 | 191/236 | Nm | |||

| Matla a enjene ea spindle S1/S6 | 30/37 | kW | |||

| Axis

| tsamaya kapele | X axis | 25 | m/m | |

| Y axis | 25 | ||||

| Z axis | 25 | ||||

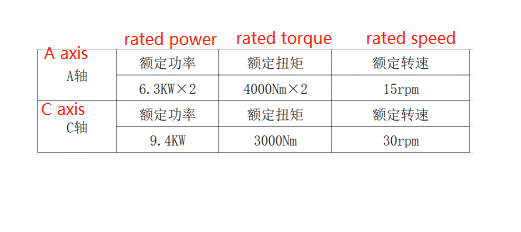

| Lebelo le phahameng la Turntable | A-axis | 15 | rpm | ||

| C axis | 30 | rpm | |||

| Matla a enjene ea X/Y/Z axis | 3.1/4.4/2 | kW | |||

| A/C axis Motlakase oa motlakase | 6.3 *2/ 9.4 | kW | |||

| A-axis | Torque e lekantsoeng | 4000×2 | Nm | ||

| C axis | Torque e lekantsoeng | 3000 | Nm | ||

| tekanyo ea phepelo e phahameng ka ho fetisisa | X/Y/Z | 25 | m/m | ||

| A/C | 15/30 | rpm | |||

| Makasine ea lisebelisoa

| Foromo ea makasine ea lisebelisoa | tshekaletseng | |||

| mokhoa oa ho khetha lisebelisoa | Khetho ea lisebelisoa tse peli tse haufi | ||||

| Tool magazine bokgoni | 30 | T | |||

| Boholo ba bolelele ba sesebelisoa | 400 | mm | |||

| Boholo ba boima ba sesebelisoa | 20 | kg | |||

| Boholo bo bophara ba hlooho ea sehahi | e tletseng dithipa | φ125 | mm | ||

| Sesebelisoa se se nang letho se haufi | φ180 | mm | |||

| boemo nepahalo | Boemo ba tsamaiso | GB/T20957.4 (ISO10791-4) | |||

| X-axis/Y-axis/Z-axis | 0.008/0.008/0.008 | mm | |||

| B axis / C axis | 8″/8″ | ||||

| pheta boemo nepahalo | X-axis/Y-axis/Z-axis | 0.006/0.006/0.006 | mm | ||

| B axis / C axis | 6″/6″ | ||||

| Boima ba mochini | 33000 | kg | |||

| kakaretso ea matla a motlakase | 80 | KVA | |||

| boholo ba moralo oa mochini | 7420×4770×4800 | mm | |||

Lethathamo la Tlhophiso

Standard

|

| 1. Likarolo tse ka sehloohong (ho kenyeletsoa motheo, kholomo, libalaka, poleiti ea li-slide, lebokose la spindle) |

| 2. X, Y, Z tsamaiso ea phepelo ea li-axis tse tharo | |

| 3. Cradle mofuta turntable AC1000 | |

| 4. Spindle ea motlakase | |

| 5. Sistimi ea taolo ea motlakase (ho kenyeletsoa khabinete ea motlakase, module ea matla, module ea servo, PLC, phanele ea ts'ebetso, ponts'o, yuniti e ts'oaroang ka letsoho, mochini oa moea oa khabinete ea motlakase, joalo-joalo) | |

| 6. Sisteme ea Hydraulic | |

| 7. Sistimi ea moea | |

| 8. Sistimi ea lubrication e bohareng | |

| 9. Metsi a pholileng | |

| 10. Chip conveyor, tanka ea metsi, pokello ea li-chip | |

| 11. 'Musi oa grating | |

| 12. Sekoahelo sa tšireletso ea terene | |

| 13. mochini ka kakaretso sekoahelo se sireletsang | |

| 14. Mokhoa oa ho lekanya oa workpiece | |

| 15. Sesebelisoa sa ho beha lisebelisoa | |

| 16. Mosebetsi oa ho lekanya ho nepahala ha li-axis tse hlano | |

|

| 1. Setifikeiti sa 1 sa ho lumellana 2. Lenane la ho paka kopi e le 'ngoe 3. Sehlopha se le seng sa buka ea mochini (mofuta oa elektroniki) 4. data backup data 1 set (U disk) Buka ea tlhahlobo ea alamo ea 5.840D Sete e le 'ngoe (phetolelo ea elektroniki)/828D tataiso ea tlhahlobo ea 1 kopi (phetolelo ea elektroniki) Buka ea ts'ebetso ea 6.840D kopi e le 'ngoe (mofuta oa elektroniki)/828D buka ea ts'ebetso ea 1 kopi (mofuta oa elektroniki) Buka ea 840D ea lenaneo Karolo e le 'ngoe ea motheo (mofuta oa elektroniki) / 828D buka ea 1 (mofuta oa elektroniki) |

| Ntho | Brands |

| X/Y/Z axis enjene le ho khanna | Siemens, Jeremane |

| ketane ea matla | Jeremane igus |

| screw bear | Japane NSK/NACHI |

| Linear Guides | Schneeberg, Jeremane |

| Makasine ea lisebelisoa | Okada |

| mofokodisi | STOBER, Jeremane |

| Lubrication e bohareng | Japane |

| Sekoti sa bolo | SHUTON, Spain |

| Likarolo tsa Pneumatic | SMC ea Japane |

| Motlakase oa khabinete ea moea ea moea | China |

| metsi a phodileng | China |

| 'musi oa grating | HEIDENHAIN, Jeremane |

| Sistimi ea ho lekanya lisebelisoa tsa mosebetsi | Renishaw, UK |

| Sistimi ea ho lekanya lisebelisoa | Renishaw, UK |

| Kopanya le mochine | Litlhaloso | Bongata |

| Mochine oa tšepe ea materase |

| 8 lihlopha |

| Liboutu tsa ankora |

| 8 lihlopha |

| mehele | M30 | 2 likotoana |

| mehele | M36 | 2 likotoana |

| suspenders |

| 1 sete |

| Allen senotlolo | 10 | 1 |

| Allen senotlolo | 12 | 1 |

| Allen senotlolo | 14 | 1 |

| Allen senotlolo | 19 | 1 |

| Thaba ea Z-axis |

| 1 |

| Sebaka sa X-axis |

| 1 |

| Ho lokisa axis ea Y |

| 1 |

Ke leboha Tlhokomelo ea Hao!