Mofuta o Otlolohileng oa Double-end Lathe

1. Likarolo tsa mochini:

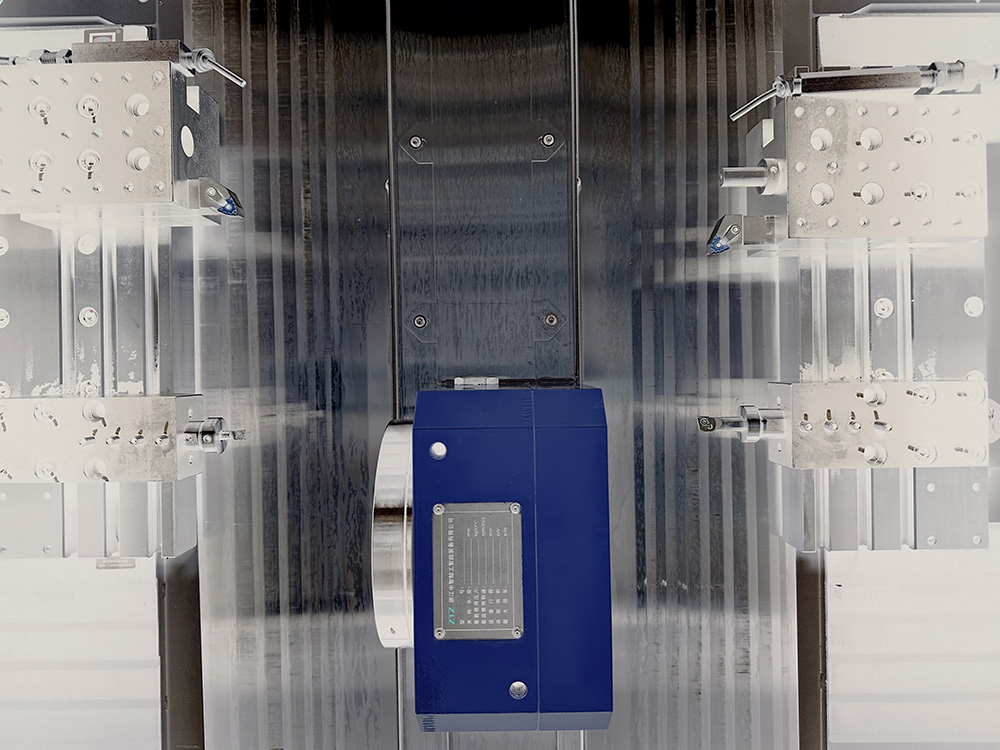

Spindle e bohareng e sebelisetsoa ho khanna workpiece ho potoloha mahlakoreng ka bobeli bakeng sa ho thinya le ho sebetsa tse ling ka nako e le 'ngoe.

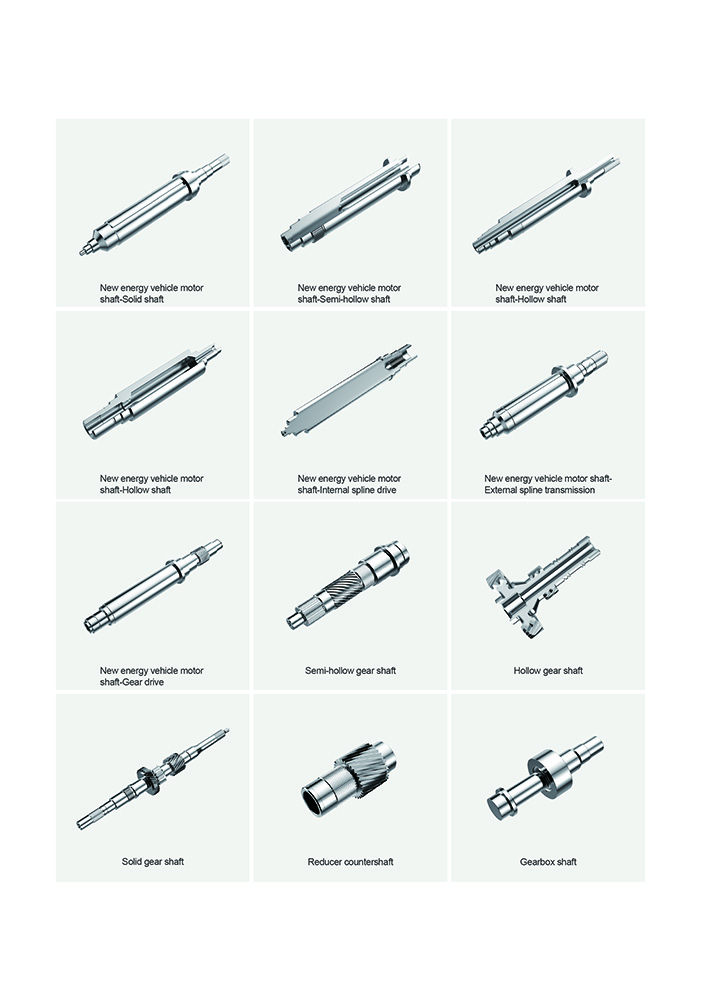

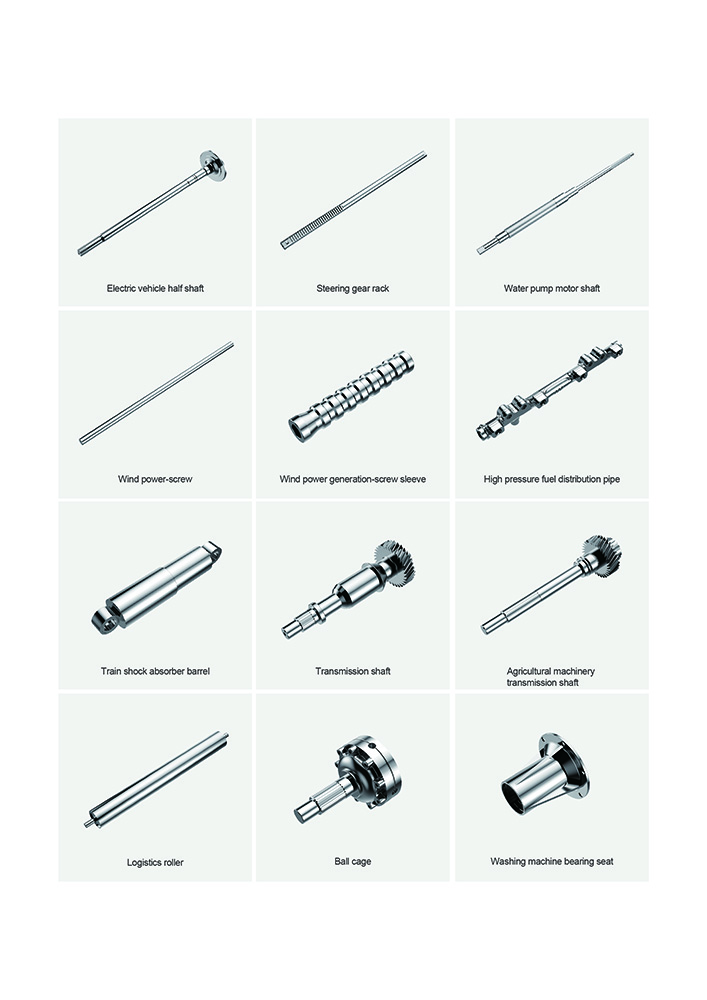

E sebelisoa ka har'a li-shafts tsa likoloi tsa motlakase tse ncha, li-shafts tsa likoloi tsa motlakase, li-shafts tsa thepa, le li-shock absorbers, li-reducer shafts, li-shaft tsa motlakase tsa pompo ea metsi le likarolo tse ling tse tloaelehileng tsa indasteri. Kopana le litlhoko tsa bareki ba maemo a holimo le a ho sebetsa ka nepo.

1.1 Ho sebetsa hantle habeli

Ha ho bapisoa le lisebelisoa tsa mochini tsa CNC tsa setso, lathe ea ZTZ e habeli e na le lisebelisoa tse peli tsa taolo, e nang le spindle e hahelletsoeng bohareng, lilepe tse peli tsa B, le lilepe tse peli tsa X, tse khonang ho sebetsa ka nako e le 'ngoe. mosebetsi ha o ntse o potoloha, o eketsa ts'ebetso ka 70% -200%.

1.2.Ho nepahala ho pheta-pheta holimo

Tataiso ea "screw screw" e nka mofuta oa boemo ba pele ba lefats'e - ha e ntse e fihlela lebelo le ts'oarelo, e boetse e netefatsa bonnete ba ho beha maemo khafetsa. Ho nepahala ha boemo ho ka tsitsisoa ho ≤0.008mm/300mm.

Ts'ebetso ea 1.3.Batch e lula e tsitsitse

Bracket e sekametseng le koloi ea B-direction e sebelisoa ho fokotsa ho senyeha ha mocheso ho bakoang ke ho itšeha ho boima le ts'ebetso e phahameng ka potlako. E loketse ho fetola margin e kholo mme e netefatsa ho nepahala ho tsitsitseng tlas'a matla a phahameng.

1.4.Matla a phahameng le ho tiea ho phahameng

HT300 ea karolo e le 'ngoe ea tšepe e entsoeng ka tšepe e na le sebopeho se nepahetseng sa ts'ehetso le matla a thata a fetang 300 MPa. Mohaho o le mong oa tšepe oa turret o na le ho tiea ho hoholo, bophelo ba nako e telele ea lisebelisoa le sesebelisoa se seholo sa ho fetola.

1.5.Likarolo tsa mantlha tsa mofuta oa pele

Ho khethoa karolo ea mantlha ea phepelo ea thepa 'me bohle ba amohela lihlahisoa tsa boemo ba pele ba malapeng le ba machabeng ho netefatsa boleng bo tsitsitseng ba sehlahisoa nakong ea ts'ebetso.

1.6.Mohato oa menoana oa mochini o kopantsoeng oa mahlakore a mane

Sehlahisoa se seng le se seng sa lisebelisoa se entsoeng ke ZTZ se na le sete e ikemetseng ea menoana ea mochini, e kenyelletsang ho nepahala ha boemo, torque, vibration le data ea ho phahama ha mocheso ha u tloha fekthering. Sistimi e kopaneng ea likarolo tse 'ne ea taolo ea boleng e felisa kahlolo ea boiphihlelo ba motho le ho lokisa liphoso habonolo.

2.Main workpieces ea habeli-qetellong lathe letoto la lihlooho tse

3. Litlhaloso tsa theknoloji

| Lebitso/Mohlala | Yuniti | SC32 | SC42 | SC52 | SC72 | SC95 | SC120 | SC160 | SC220 |

| Max. clamp bophara | mm | 32 | 42 | 52 | 72 | 95 | 120 | 160 | 220 |

| Max. bolelele | mm | 300 | 400 | 400 | 400 | 400 | 600 | 600 | 600 |

| Min. bolelele | mm | 100 | 100 | 100 | 200 | 200 | 200 | 200 | 300 |

| Lebelo la spindle | r/mets | 3500 | 3000 | 2500 | 2000 | 1600 | 1200 | 1000 | 800 |

| Matla a enjene ea spindle | Kw | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 11 | 15 |

| Z lebelo la axis | m/m | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| X lebelo la axis | m/m | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Z guide seporo max maeto | mm | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| X guide rail max trave | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Boima ba 'mele | Kg | 4000 | 4000 | 4000 | 4000 | 4500 | 4500 | 4500 | 5000 |

| Boholo | mm | 2800x2080x1695 | 2800x2080x1695 | 2800x2080x1695 | 2800x2080x1695 | 2800x2080x1695 | 2800x2080x1695 | 2800x2080x1900 | 3300x2080x1900 |