BOSM-1601 Bahanyetsi-Hlooho Boring Milling Machiner

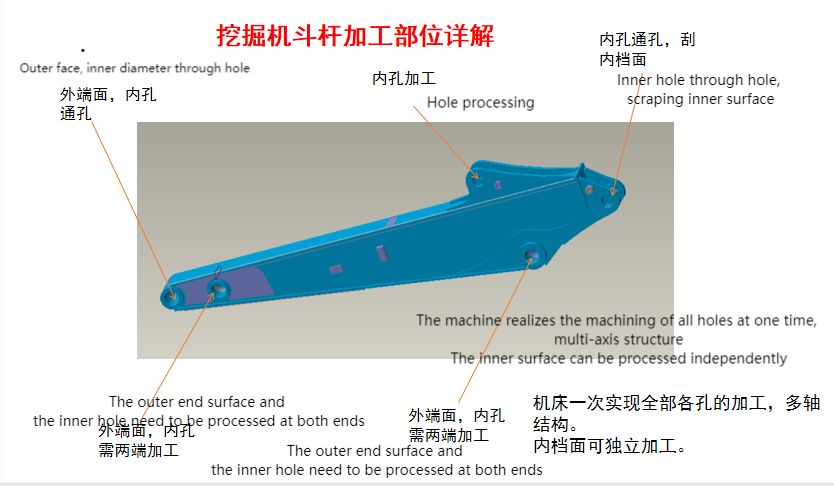

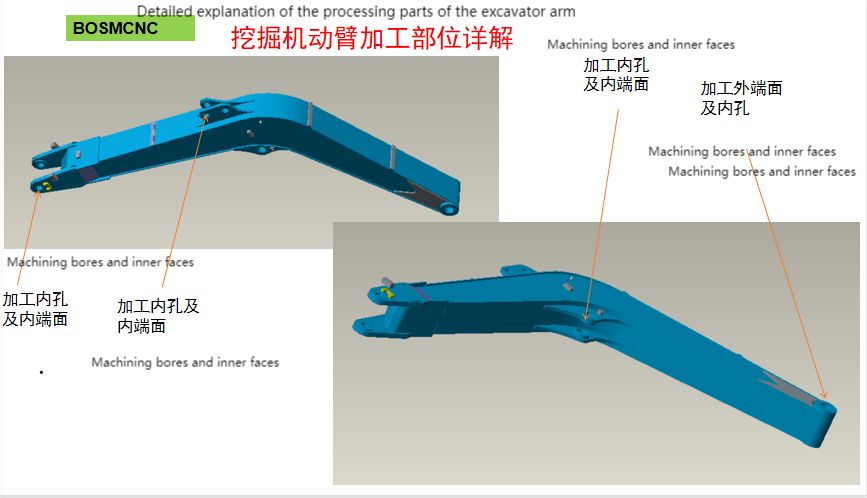

1. Tšebeliso ea lisebelisoa

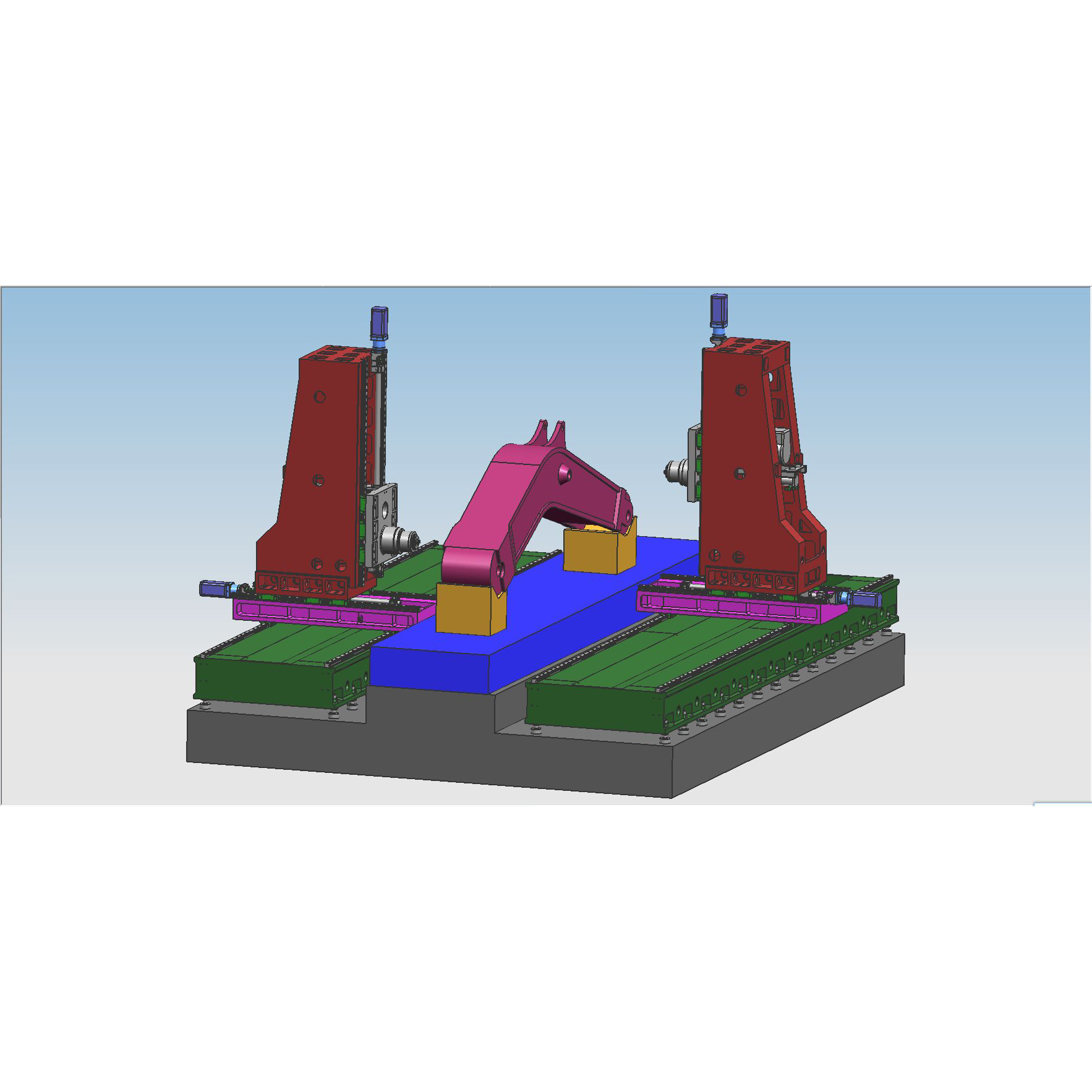

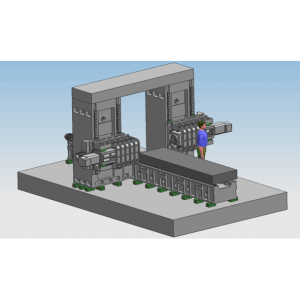

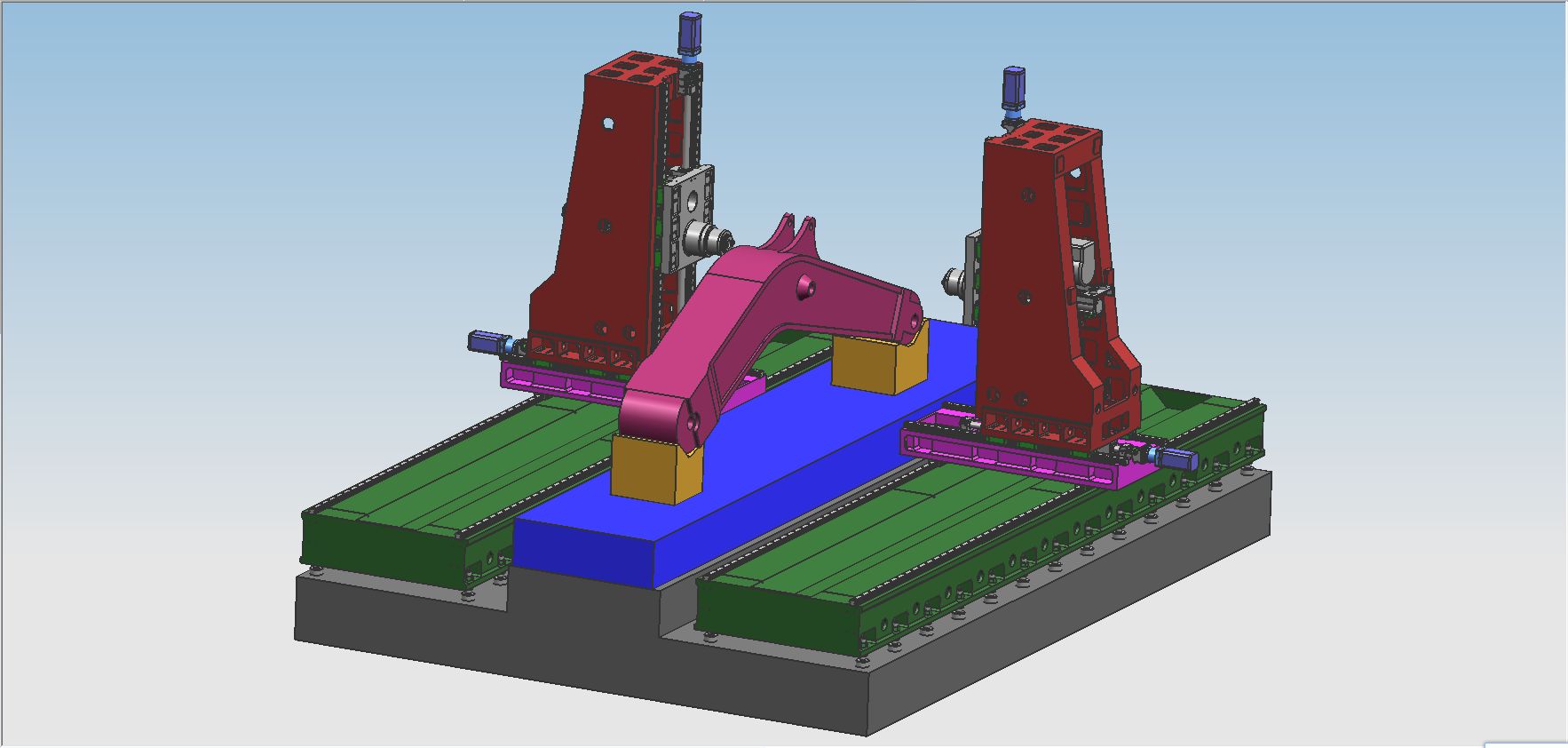

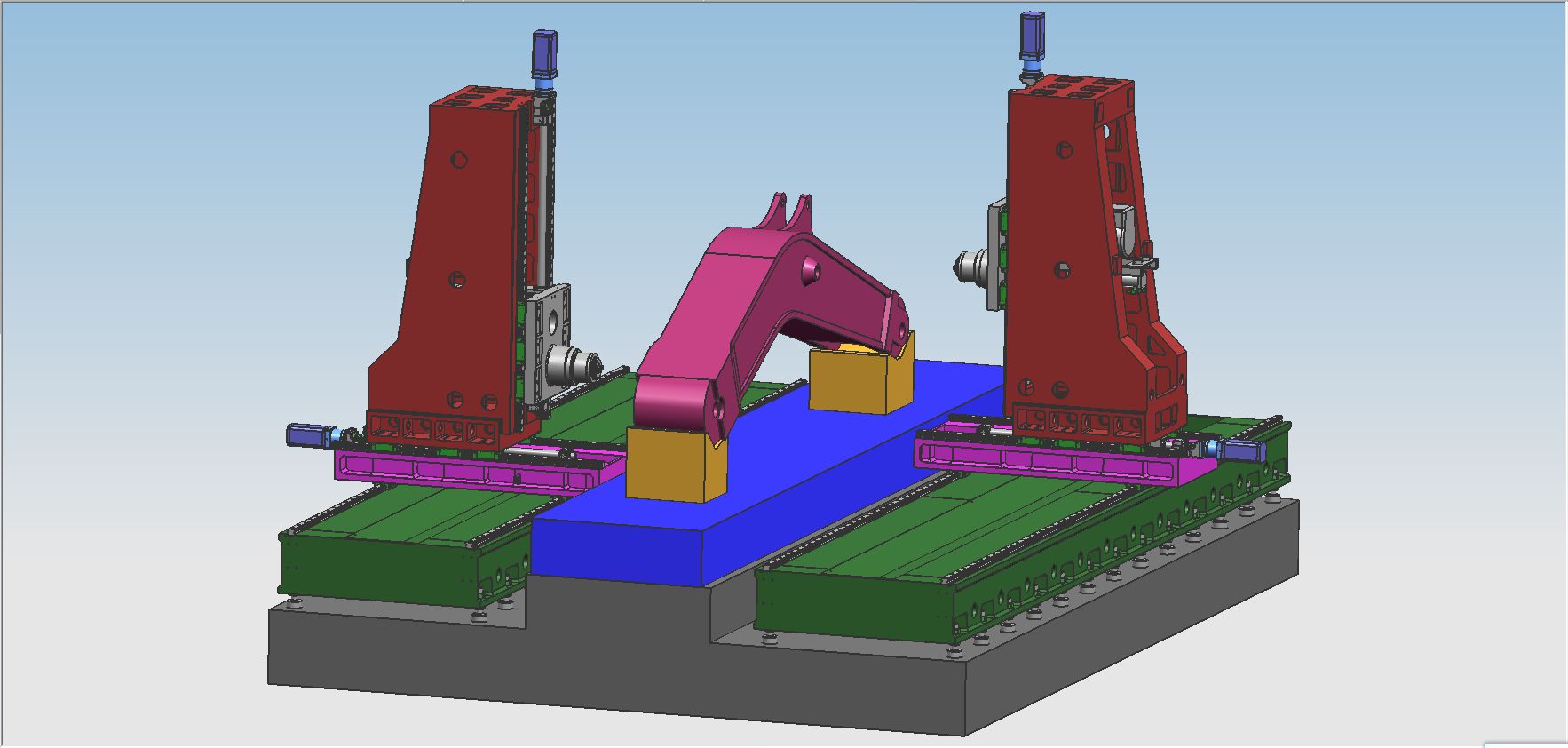

BOSM-1601 e nang le liteishene tse peli tsa taolo ea linomoro mohala oa mohala o nang le mekoloko e 'meli ea hlooho ho isa hloohong o tenang le mochini o silang ke Mochini o ikhethileng bakeng sa lisebelisoa tse lekanang tsa mochini oa kaho.Mochini o na le litšiea tse khethehileng tse tsamaisoang le lihlopha tse peli tsa lipheleu tse otlolohileng, tse ka hlokomelang ho cheka, ho sila, ho boreha le ts'ebetso e 'ngoe ea sesebelisoa ka har'a sebaka se sebetsang sa stroke, sesebelisoa se ka sebetsoa sebakeng ka nako e le' ngoe (ha ho na tlhoko ea bobeli. clamping), ho potlakisa ho potlakisa le ho theola lebelo, lebelo la boemo bo potlakileng, ho nepahala ha ts'ebetso e phahameng le ts'ebetso e phahameng ea ts'ebetso.

2. Likarolo tse ka sehloohong tsa Mochine

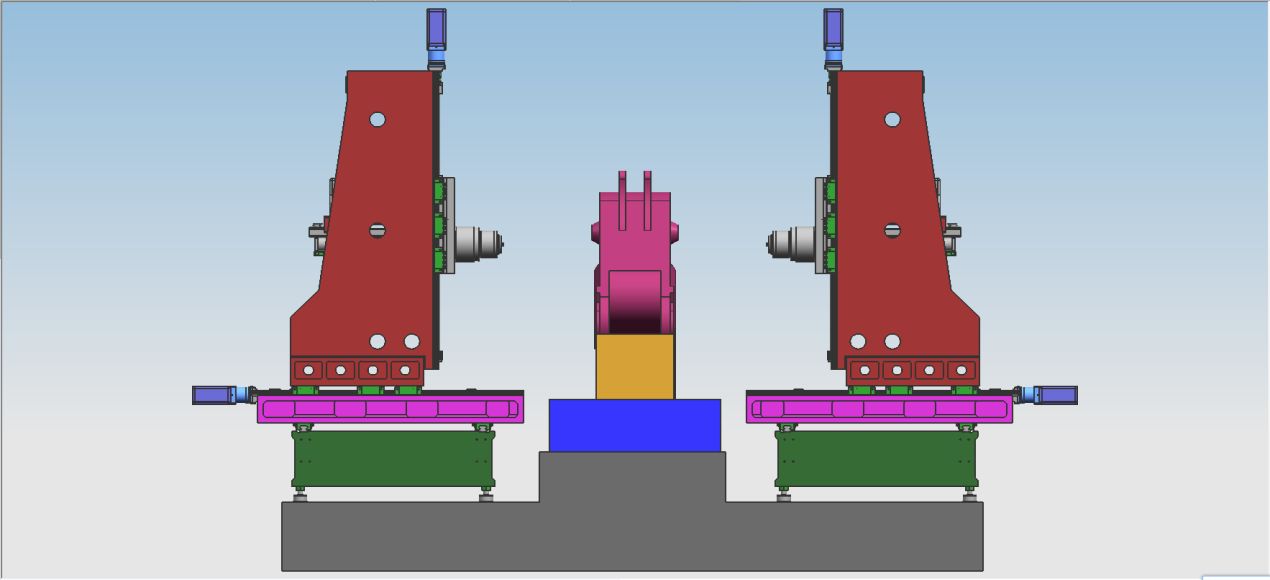

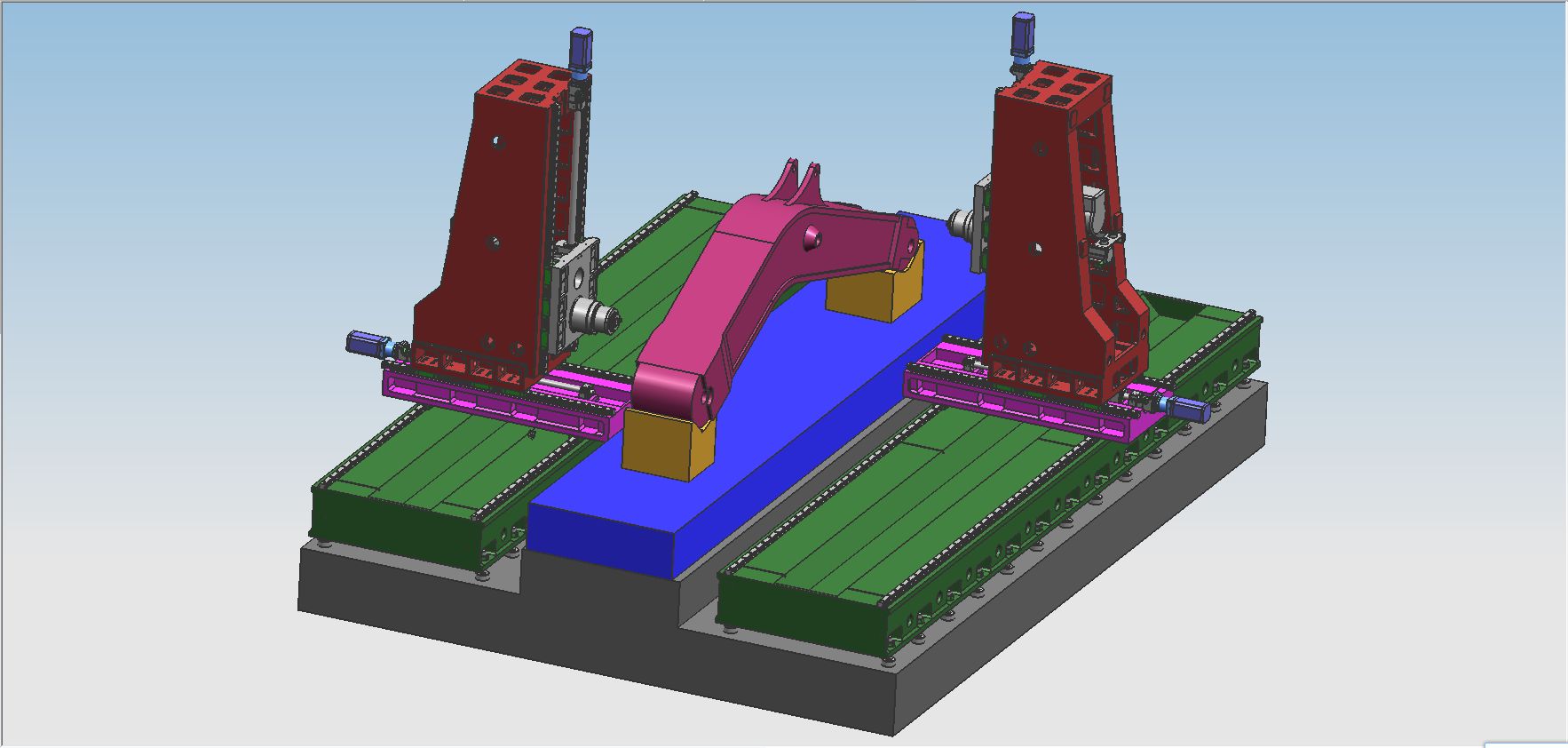

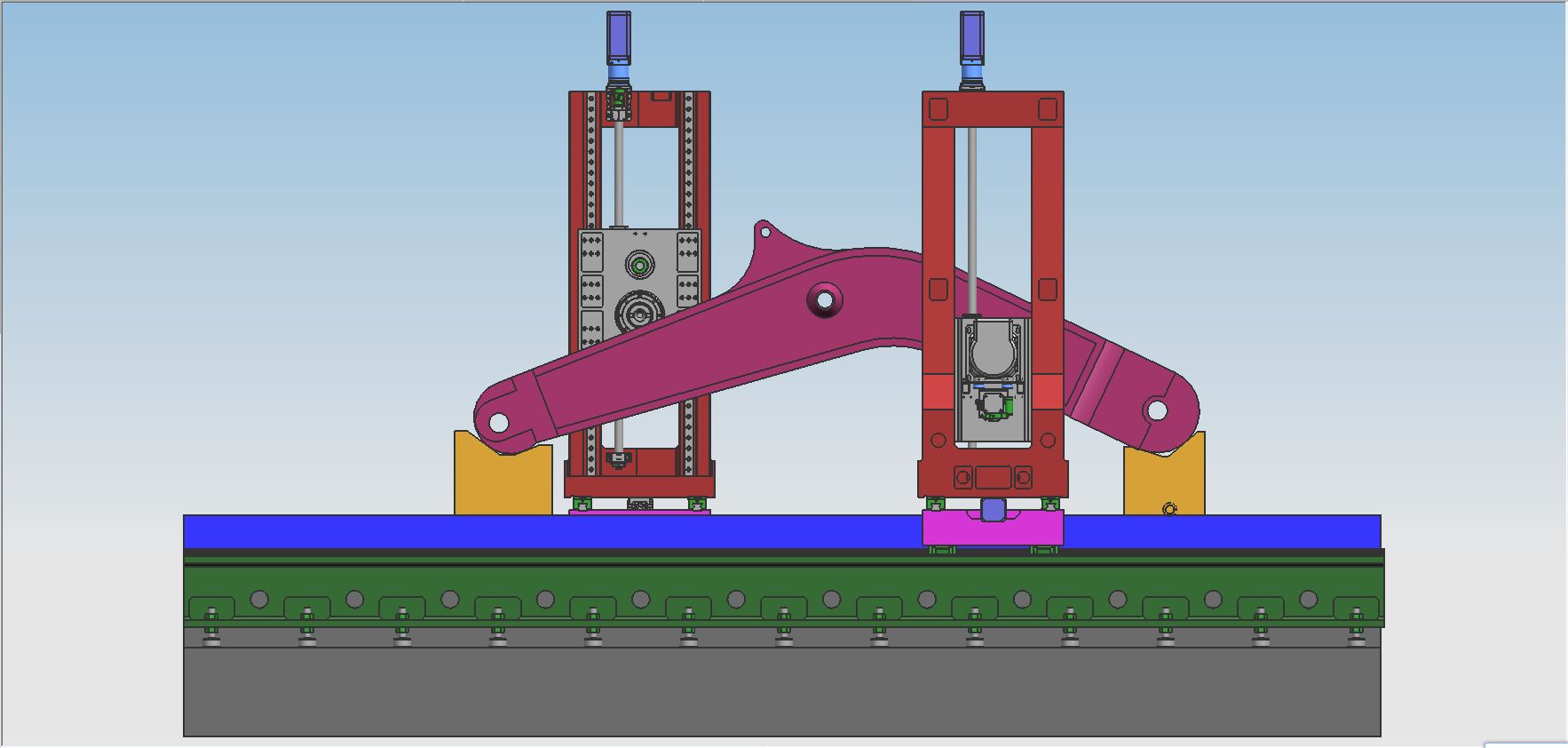

Bethe, setulo sa mosebetsi, litšiea tse ka letsohong le letšehali le ka ho le letona, maballo, liseile, lipheleu le likarolo tse ling tse kholo li entsoe ka ho bopeha ha lehlabathe la resin, tšepe ea boleng bo holimo ea 250, e kentsoeng ka mokoting oa lehlabathe le chesang → ho tsofala ha thothomelo→ sebopi se chesang → botsofali ba thothomelo→ ho sebetsa ka thata→ botsofali ba ho sisinyeha → sebōpi se chesang → botsofali ba ho sisinyeha → ho qeta, felisa ka botlalo khatello e mpe ea likarolo, 'me u boloke tšebetso ea likarolo e tsitsitse.Mochini o na le mesebetsi e kang ho sila, ho bora, ho phunya, ho qoelisa, ho tlanya, joalo-joalo, 'me mokhoa oa ho pholile oa sesebelisoa ke ho pholisa ka ntle, Mochini o na le lilepe tse 6 tsa phepelo, tse ka hlokomelang khokahano ea 4-axis le 6-axis single-ketso.Ho na le lihlooho tse 2 tsa matla.Tataiso ea axial ea Mochini le hlooho ea matla e bontšitsoe setšoantšong se ka tlase.

2.1Sebopeho se seholo sa karolo ea phepelo ea phepelo ea axial

2.1.1 X1/X2 axis:Kholomo e khutlisetsoa ka longitudinal haufi le seporo sa tataiso ea bethe e tsitsitseng.

Phetiso ea X-axis: E khannoa ebile e laoloa ke enjene ea AC servo, se fokotsang lipolanete tse nepahetseng haholo se khanna litšiea tse peli hore li tsamaee ka tsela e tsamaellanang le X-axis ka har'a para ea phetiso ea bolo.

Foromo ea seporo sa tataiso: Lithaele tse peli tse matla tse phahameng tse nepahetseng li behiloe sephara.Kereiti e nepahetseng ea screw ea bolo para ea phetiso ke C5.

2.1.2 Y1/Y2 axis:Lihlooho tsa matla a boreleli le li-milling I, II le litšiea tsa tsona li kentsoe ka ho latellana holim'a liporo tsa tataiso tse matla ka mahlakoreng ka bobeli, 'me li khutlisetsoa morao ho liporo tsa tataiso tsa motheo haufi le lilepe tsa Y1 le Y2.Enjene ea AC servo e sebelisoa ho khanna le ho laola para ea phetiso ea bolo, ho hula sale ho tsamaea, le ho hlokomela motsamao oa mola o haufi le Y axis.

Foromo ea seporo sa tataiso: 4 linear guide rails + ball screw drive.Kereiti ea ho nepahala ea sekoti sa bolo ka har'a para ea phetiso ke C5, 'me taolo ea semi-closed-loop e amoheloa.

2.1.3 Z1/Z2 axis:Lihlooho tsa matla a boreleli le li-milling I, II le li-saddles tsa tsona tse thellang li kentsoe ka kotloloho lipheletsong tse ka pele tsa litšiea ka mahlakoreng ka bobeli, 'me li khutlisa lilepe tsa Z1 le Z2 holimo le tlase liporong tsa tataiso.

Phetiso ea Z1-axis: AC servo motor e sebelisetsoa ho khanna le ho laola mochine o fokotsang lipolanete le li-ball screw transmission para pair, 'me pheleu e khannoa hore e tsamaee ka mokhoa o latellanang haufi le Z-axis.

Foromo ea seporo sa tataiso: Ho amoheloa meaho e 2 ea seporo sa linear.Kereiti ea ho nepahala ha screw screw para transmission pair ke C5.

2.2 Ho tlosoa ha chip le ho pholile

Ho na le li-conveyor tsa spiral le tse bataletseng tsa ketane ea ketane e kentsoeng mahlakoreng ka bobeli tlasa benche ea mosebetsi, 'me lichifi li ka fetisetsoa ka botsona ho mochini o tsamaisang chip qetellong ka mekhahlelo e' meli ea lipoleiti tsa spiral le ketane ho fihlela tlhahiso e tsoetseng pele.Ho na le pompo e pholileng ka har'a tanka e pholisang ea mochini o tsamaisang chip, e ka sebelisetsoang ho pholisa kantle ho sesebelisoa ho netefatsa ts'ebetso le bophelo ba ts'ebeletso ea sesebelisoa, 'me se pholisang se ka sebelisoa hape.

3.Sistimi e felletseng ea taolo ea linomoro tsa dijithale:

3.1.Ka ts'ebetso ea ho pshatla ha chip, nako ea ho robeha ha chip le potoloho ea ho robeha ha chip e ka beoa sebopehong sa mochini oa motho.

3.2.E na le ts'ebetso ea ho phahamisa lisebelisoa, sebaka sa ho phahamisa sesebelisoa se ka beoa sebopehong sa mochini oa motho.Ha sebaka se fihla, sesebelisoa se phahamisoa ka potlako, ebe li-chips li lahleloa, ebe li fetisetsoa ka potlako sebakeng sa ho phunya ebe se fetoloa ka bohona ho sebetsa.

3.3.Lebokose la taolo ea ts'ebetso e bohareng le yuniti e ts'oaroang ka letsoho e amohela sistimi ea taolo ea linomoro 'me e na le sebopeho sa USB le ponts'o ea kristale ea metsi ea LCD.E le ho nolofatsa mananeo, polokelo, pontšo le puisano, sebopeho sa ts'ebetso se na le mesebetsi e kang puisano ea mochine oa motho, matšeliso a phoso, le alamo e ikemetseng.

3.4.Thepa e na le mosebetsi oa ho hlahloba le ho hlahloba hape sebaka sa sekoti pele se sebetsa, 'me ts'ebetso e bonolo haholo.

4.Lubrication e iketsang

Lipara tsa literene tse nepahetseng tsa mochini, li-screw screw pairs le lipara tse ling tse tsamaeang hantle haholo li na le lisebelisoa tsa boiketsetso.Pompo e itšebetsang e ntša oli ea khatello, 'me kamore ea oli ea lubricator e kenang ka har'a oli.Ka mor'a hore kamore ea oli e tlatsitsoe ka oli, ha khatello ea tsamaiso e nyolohela ho 1.4-1.75Mpa, mochine oa khatello tsamaisong o koetsoe, pompo e emisa, 'me valve ea ho laolla e theoha ka nako e le' ngoe.Ha khatello ea oli tseleng e theoha ka tlase ho 0.2Mpa, lubricator ea bongata e qala ho tlatsa ntlha ea ho tlotsa ebe e phethela ho tlatsa oli e le 'ngoe.Ka lebaka la phepelo e nepahetseng ea oli ea ente ea oli e ngata le ho lemoha khatello ea sistimi, phepelo ea oli e ea tšepahala, ho netefatsa hore ho na le filimi ea oli holim'a para e 'ngoe le e' ngoe ea kinematic, e fokotsa ho ferekana le ho roala, le ho thibela tšenyo ea li-kinematic. sebopeho sa ka hare se bakoang ke mocheso o feteletseng., ho etsa bonnete ba ho nepahala le bophelo ba Machine.Ha ho bapisoa le seporo sa tataiso e thellang, seporo sa mehala e tataisang se sebelisoang Mochineng ona se na le letoto la melemo:

① Boikutlo bo phahameng ba ho sisinyeha, coefficient ea likhohlano tsa seporo sa seporo se nyane, ke 0.0025-0.01 feela, mme matla a ho khanna a fokotsehile haholo, a lekanang le 1 ea mochini o tloaelehileng./10.

② Phapang pakeng tsa khohlano e matla le e tsitsitseng e nyane haholo, 'me ts'ebetso ea ho latela e ntle haholo, ke hore, nako ea nako lipakeng tsa lets'oao la ho khanna le ketso ea mochini e khuts'oane haholo, e thusang ho ntlafatsa lebelo la karabo le kutlo. tsamaiso ea lipalo. ③E loketse ho sisinyeha ka lebelo le holimo, 'me lebelo la eona hang-hang le ka holimo ho makhetlo a 10 ho feta la liporo tsa tataiso tse thellang.④ E khona ho lemoha motsamao o se nang lekhalo le ho ntlafatsa ho sisinyeha ha motsamao oa mochini.⑤E entsoe ke baetsi ba litsebi, e na le ho nepahala ho phahameng, ho feto-fetoha ha maemo le tlhokomelo e bonolo.

5.Tikoloho ea tšebeliso ea mochini:

5.1.Litlhoko tsa tikoloho bakeng sa tšebeliso ea lisebelisoa

Ho boloka boemo bo sa khaotseng ba mocheso oa tikoloho ke ntho ea bohlokoa bakeng sa ho sebetsa ka nepo.

(1) Litlhoko tse teng tsa mocheso oa tikoloho ke -10°C ho isa ho 35°C, ha mocheso o phelang o le 20°C, mongobo o lokela ho ba 40% ho isa ho 75%.

(2) E le ho boloka ho nepahala ho tsitsitseng ha Mochini ka har'a mefuta e boletsoeng, mocheso o nepahetseng o lokela ho ba 15 ° C ho 25 ° C, le phapang ea mocheso.

Ha ea lokela ho feta ±2°C/24h.

5.2 Matla a matla a matla: 3-mohato, 380V, ka har'a mefuta e mengata ea ± 10% ea ho fetoha ha motlakase, maqhubu a phepelo ea matla: 50HZ.

5.3 Haeba motlakase sebakeng sa ho sebetsa o sa tsitsa, Mochini o lokela ho hlomelloa ka matla a tsitsitseng ho netefatsa ts'ebetso e tloaelehileng ea Mochini.

5.4 Mochini o lokela ho ba le motheo o tšepahalang: terata ea fatše ke terata ea koporo, bophara ba terata ha ea lokela ho ba ka tlase ho 10mm², 'me ho hanyetsa fatše ho nyane ho isa ho 4 ohms.

5.5 E le ho netefatsa ts'ebetso e tloaelehileng ea ts'ebetso ea lisebelisoa, haeba moea o hatelitsoeng oa mohloli oa moea o ke ke oa finyella litlhoko tsa mohloli oa moea, o lokela ho kenngoa Mochineng.

Kenya sete ea sesebelisoa sa tlhoekiso ea moea (dehumidification, degreasing, filtering) pele ho moea.

5.6 Boloka lisebelisoa hole le mahlaseli a letsatsi, ho sisinyeha le mehloli ea mocheso, lijenereithara tse nang le maqhubu a mangata, mechine ea ho tjheseletsa ka motlakase, joalo-joalo, e le ho qoba ho hlōleha ha tlhahiso ea Mochini kapa ho lahleheloa ke ho nepahala ha Mochine.

6.Litekanyetso tsa tekheniki

| Mohlala | 1601 | |

| Ho sebetsa boholo ba workpiece | Bolelele × bophara × bophahamo (mm) | 16000×1000×1500 |

| Boholo ba fepa ka mochini | Bophara (mm) | 1300 |

| Saese ea deske e sebetsang | Bolelele X Bophara (mm) | 16000*1000 |

| Column maeto | Kholomo e ea pele le morao (mm) | 1600 |

| Spindle holimo le tlase | Maeto a holimo le tlase (mm) | 1500 |

| Bophahamo ho tloha setsing sa spindle ho isa sefofaneng sa tafole | 100-1600 limilimithara | |

| Orizontal phahameng matla spindle matla hlooho e 'ngoe tse peli | Bongata (2) | 2 |

| Spindle taper | BT50 | |

| Broach | Broaching e iketsang, phetoho ea sesebelisoa sa matsoho | |

| Sekhahla sa bophara (mm) | ≤Φ200 | |

| Bophara ba ho tlanya (mm) | M3-M30 | |

| Lebelo la spindle (r/min) | 30-3000 | |

| Servo spindle motor power (kw) | 30*2 | |

|

| Sebaka sa leeto le letšehali le le letona pakeng tsa lipheletso tse peli tsa spindle | 400-1600 limilimithara |

| Leeto le letšehali le le letona la litšiea tse peli (mm) | 600 e le 'ngoe | |

| Tool Cooling | Ho pholisa ka hare, ho pholisa ka ntle | |

| Ho Nepaha ha Boemo ba Bidirectional | 300 limilimithara | ±0.032 |

| Ho nepahala ho pheta-pheta maemo a mabeli | 300 limilimithara | ±0.025 |

| Litekanyo tsa Mochini | Bolelele × bophara × bophahamo (mm) | Ho latela lits'oants'o (haeba ho na le liphetoho ts'ebetsong ea moralo, re tla u tsebisa) |

| Boima ba 'mele (t) | 72T | |