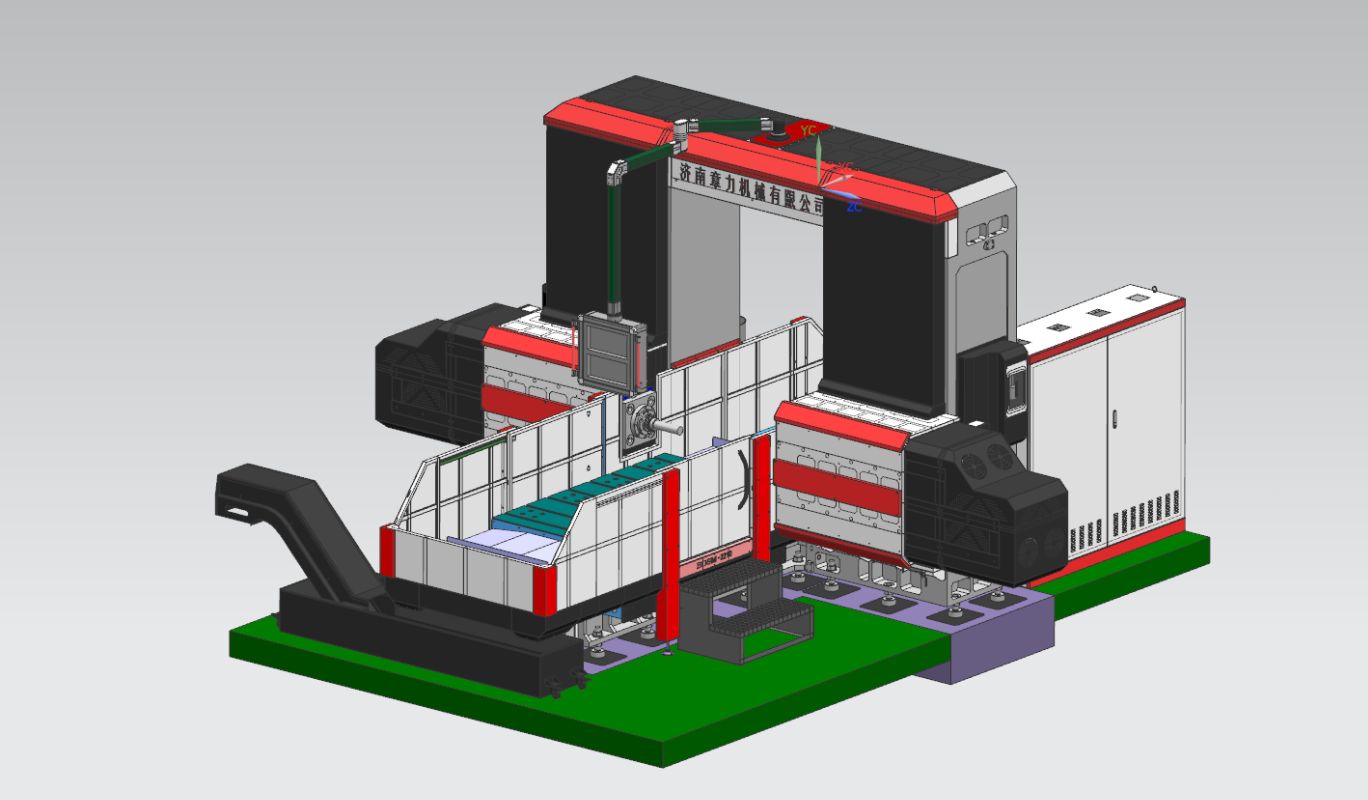

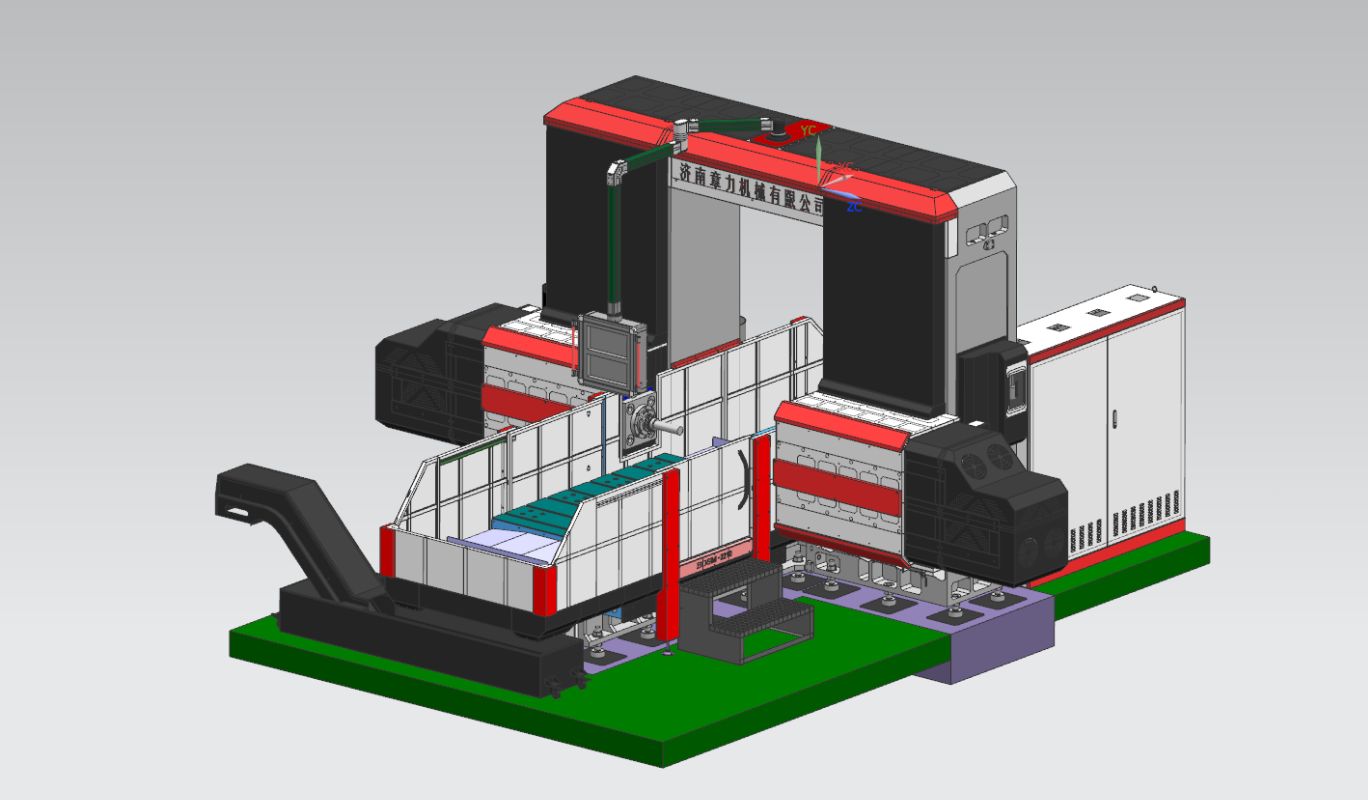

BOSM -5020-5Z Mochine o Hanyetsang-Hlooho ea Boring Milling

1.Tšebeliso ea lisebelisoa:

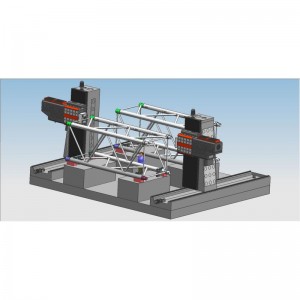

BOSM-5020-5Z CNC workbench mobile-column double-column head-to-head boring and milling machine ke Mochini o khethehileng oa mochini oa boenjineri oa li-symmetrical workpieces.Mochini o na le benche e khethehileng e tsamaisoang le lihlopha tse peli tsa lipheleu tse otlolohileng, tse ka hlokomelang ho cheka, ho sila, ho bora le ts'ebetso e 'ngoe ea sesebelisoa ka har'a sebaka se sebetsang sa stroke, sesebelisoa se ka sebetsoa sebakeng se le seng (ha ho hlokahale secondary clamping), lebelo la ho palamisa le ho laolla, lebelo la ho beha maemo ka potlako, ho nepahala ha ts'ebetso e phahameng le ts'ebetso e phahameng ea ts'ebetso.

2.Sebopeho sa lisebelisoa:

2.1. Likarolo tse ka sehloohong tsa Mochine

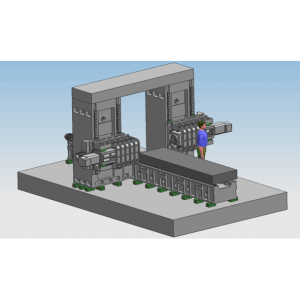

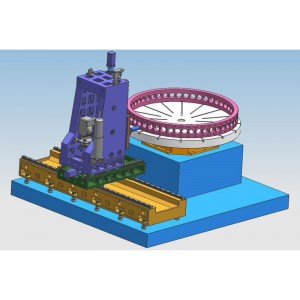

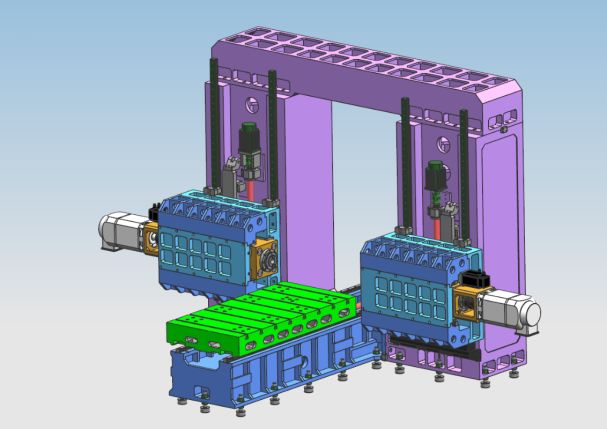

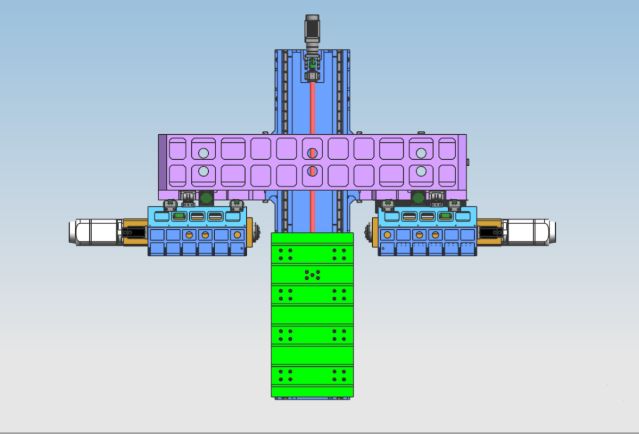

Bethe, benche ea mosebetsi, litšiea tse ka letsohong le letšehali le ka ho le letona, maballo, maballo a kopanyang, liseile, lipheleu, joalo-joalo, kaofela li entsoe ka ho bopeha ha lehlabathe la resin, tšepe ea boleng bo holimo ea 250, e kentsoeng ka sekoting sa lehlabathe le chesang → ho tsofala ha vibration → → ho tsofala ho sisinyeha → ho sebetsa ka thata → botsofali ba ho sisinyeha → ho thothomela ka ontong → botsofali ba ho sisinyeha → ho qeta, felisa ka botlalo khatello e mpe ea likarolo, 'me u boloke tšebetso ea likarolo e tsitsitse.Bethe e tsitsitseng, litšiea tse ka ho le letšehali le tse nepahetseng, gantry, le sebaka sa mosebetsi se tsamaeang;Mochini o na le ho sila, ho khaola, ho cheka, ho qoelisoa, ho tlanya le mesebetsi e meng, mokhoa oa ho pholisa sesebelisoa ke ho pholisa ka ntle, Mochini o na le lilepe tse 5 tsa phepelo, tse ka hlokomelang khokahano ea 4-axis, 5-axis single-ketso, lihlooho tse 2 tsa matla. , Machine axial le Hlooho ea matla e bontšoa setšoantšong se ka tlase.

2.2. Sebopeho se seholo sa karolo ea phepelo ea phepelo ea axial

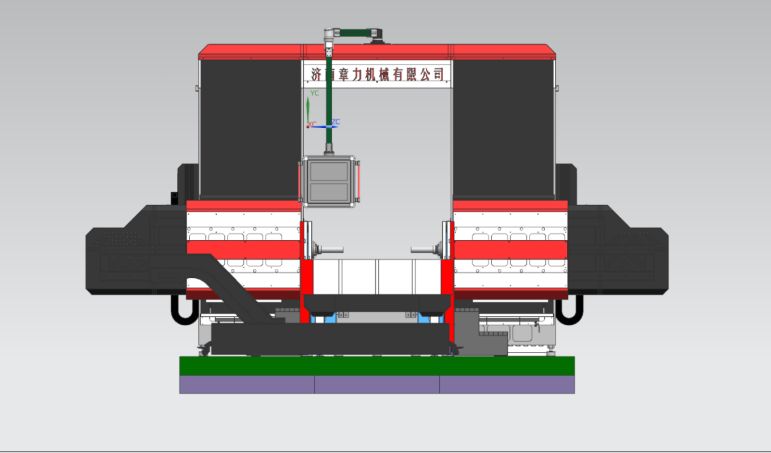

2.2.1.X-axis: The worktable reciprocates ka thōko haufi le seporo sa tataiso ea bethe e tsitsitseng.

Phetiso ea X-axis: AC servo motor le mochini o fokotsang lipolanete o nepahetseng haholo li sebelisoa ho khanna tafole ea ho sebetsa ka phetiso ea screw ea bolo ho lemoha motsamao oa mohala oa X-axis.

Foromo ea seporo sa tataiso: rala liporo tse peli tse matla tse phahameng

2.2.2.Y1 axis: Hlooho ea matla le pheleu li kentsoe ka ho otloloha ka lehlakoreng le ka pele la kholomo, 'me li khutlisetsa ka ho le letšehali le ka ho le letona haufi le seporo sa tataiso sa kholomo.

Phetisetso ea Y1-axis: AC servo motor e sebelisoa ho khanna screw screw ho khanna sale ho tsamaea, le ho hlokomela motsamao oa Y1-axis linear.

Foromo ea terene ea tataiso: likotoana tse 4 tsa mefuta e 45 ea mela e tataisang.

2.2.3.Y2 axis: Pheleu ea bobeli ea hlooho ea matla e kenngoa ka holimo ka lehlakoreng le ka pele la kholomo, 'me e khutlisetsa ka ho le letšehali le ka ho le letona ho latela seporo sa tataiso sa kholomo.

Phetisetso ea Y2-axis: AC servo motor e sebelisoa ho khanna screw screw ho khanna motsamao oa saddle ho hlokomela motsamao oa mela ea Y1-axis.

Foromo ea terene ea tataiso: likotoana tse 4 tsa mefuta e 45 ea mela e tataisang

2.2.4.Z1 axis: Saddle ea matla e thellang e kentsoe ka holimo ka lehlakoreng le ka pele la kholomo e ka ho le letona, 'me e khutlela holimo le tlase ho latela seporo sa tataiso ea kholomo.

Phetiso ea Z1-axis: AC servo motor le mochini o fokotsang lipolanete tse nepahetseng haholo li sebelisoa ho khanna pheleu hore e tsamaee ka har'a sekoti sa bolo ho lemoha motsamao oa mola oa Z1-axis.

Foromo ea seporo sa tataiso: 2 65 mofuta oa linear guide rails

2.2.5.Z2 axis: Saddle head slide saddle e kentsoe ka ho otloloha ka lehlakoreng le ka pele la kholomo e ka ho le letona, 'me e khutlela holimo le tlase ho latela seporo sa tataiso ea kholomo.

Phetisetso ea Z1-axis: AC servo motor hammoho le mochini o fokotsang polanete o nepahetseng haholo o sebelisoa ho khanna pheleu hore e tsamaee ka har'a sekoti sa bolo ho lemoha motsamao oa mola oa Z2-axis.

Foromo ea seporo sa tataiso: 2 65 mofuta oa linear guide rails

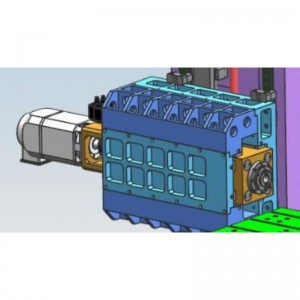

HT250 ea boleng bo holimo ea ho lahla likotoana tse 2 tsa mefuta e 65 ea liporo tsa mehala e boima

Hlooho ea matla a boreleli le a ho sila (ho kenyeletsoa hlooho ea matla 1 le 2) ke pheleu ea lisekoere tse kopantsoeng, 'me tsela e tsamaeang e tataisoa ke li-rails tse 4 tsa linear roller guide.Koloi e sebelisa enjene ea AC servo ho khanna sekoti se nepahetseng sa bolo.Mochine o na le thipa ea nitrogen balance., Fokotsa matla a ho jara a hlooho ea mochini holim'a screw le servo motor.Enjene ea Z-axis e na le tšebetso ea brake ea othomathike.Haeba motlakase o hloleha, brake ea othomathiki e tla tšoara shaft ea enjene ka thata hore e se ke ea potoloha.Ha o sebetsa, ha sekhahla sa ho phunya se sa ama sesebediswa, se tla fepa ka potlako;ha drill bit ama workpiece, e tla ka tsela e iketsang switjha ho sebetsa phepelo.Ha drill bit e phunyeletsa workpiece, e tla ka tsela e iketsang switjha ho itima lijo rewind;ha qetello ea "drill bit" e tloha ho workpiece 'me e fihla sebakeng se behiloeng, e tla fallela sebakeng se latelang sa lesoba ho lemoha ho potoloha ka mokhoa o itekanetseng.'Me e ka hlokomela mesebetsi ea ho phunya masoba a foufetseng, ho sila, ho phunya, ho pshatla li-chip, ho tlosa li-chips, joalo-joalo, e ntlafatsang tlhahiso ea basebetsi.

The 500mm stroke compound square ram power head e sebelisa linear guides ho fapana le tse kentsoeng tsa setso ho ntlafatsa haholo ho nepahala ha tataiso ha e ntse e boloka ho tiea ha square ram.

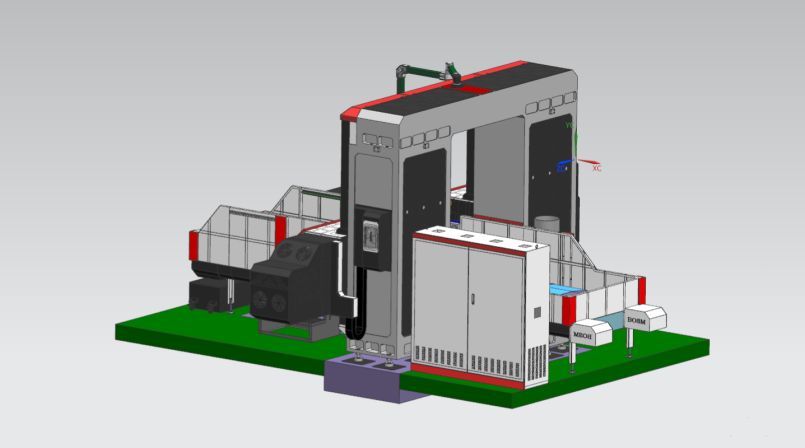

2.3. Ho tlosoa ha chip le ho pholile

Ho na le li-conveyor tsa spiral le tse bataletseng tsa ketane ea ketane e kentsoeng mahlakoreng ka bobeli tlasa benche ea mosebetsi, 'me lichifi li ka fetisetsoa ka botsona ho mochini o tsamaisang chip qetellong ka mekhahlelo e' meli ea lipoleiti tsa spiral le ketane ho fihlela tlhahiso e tsoetseng pele.Ho na le pompo e pholileng ka har'a tanka e pholisang ea mochini o tsamaisang chip, e ka sebelisetsoang ho pholisa kantle ho sesebelisoa ho netefatsa ts'ebetso le bophelo ba ts'ebeletso ea sesebelisoa, 'me se pholisang se ka sebelisoa hape.

3.Sistimi e felletseng ea taolo ea linomoro tsa dijithale:

3.1.Ka ts'ebetso ea ho pshatla ha chip, nako ea ho robeha ha chip le potoloho ea ho robeha ha chip e ka beoa sebopehong sa mochini oa motho.

3.2.E na le ts'ebetso ea ho phahamisa lisebelisoa, sebaka sa ho phahamisa sesebelisoa se ka beoa sebopehong sa mochini oa motho.Ha sebaka se fihla, sesebelisoa se phahamisoa ka potlako, ebe li-chips li lahleloa, ebe li fetisetsoa ka potlako sebakeng sa ho phunya ebe se fetoloa ka bohona ho sebetsa.

3.3.Lebokose la taolo ea ts'ebetso e bohareng le yuniti e ts'oaroang ka letsoho e amohela sistimi ea taolo ea linomoro 'me e na le sebopeho sa USB le ponts'o ea kristale ea metsi ea LCD.E le ho nolofatsa mananeo, polokelo, pontšo le puisano, sebopeho sa ts'ebetso se na le mesebetsi e kang puisano ea mochine oa motho, matšeliso a phoso, le alamo e ikemetseng.

3.4.Thepa e na le mosebetsi oa ho hlahloba le ho hlahloba hape sebaka sa sekoti pele se sebetsa, 'me ts'ebetso e bonolo haholo.

4.Lubrication e iketsang

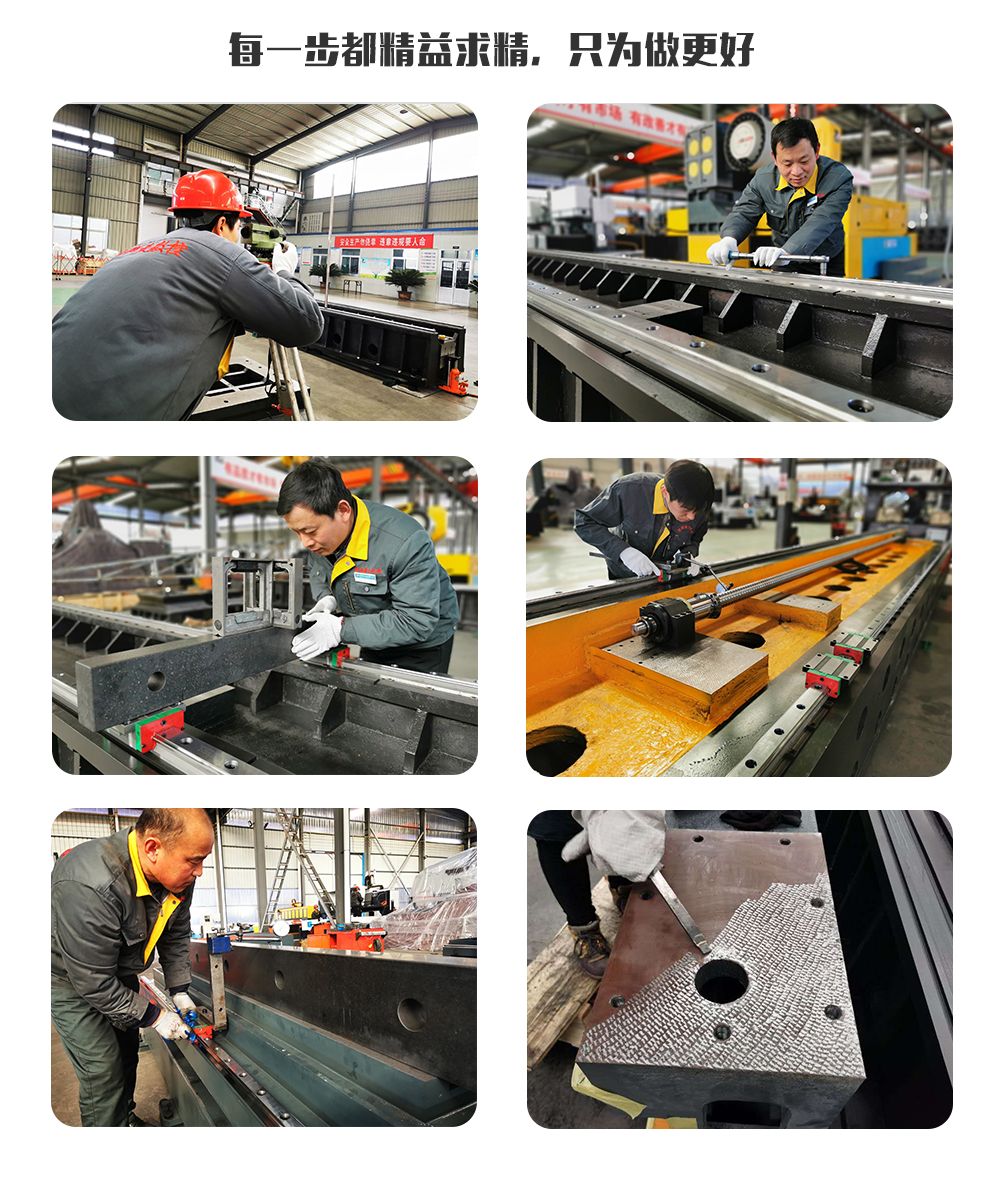

Lipara tsa literene tse nepahetseng tsa mochini, li-screw screw pairs le lipara tse ling tse tsamaeang hantle haholo li na le lisebelisoa tsa boiketsetso.Pompo e itšebetsang e ntša oli ea khatello, 'me kamore ea oli ea lubricator e kenang ka har'a oli.Ka mor'a hore kamore ea oli e tlatsitsoe ka oli, ha khatello ea tsamaiso e nyolohela ho 1.4-1.75Mpa, mochine oa khatello tsamaisong o koetsoe, pompo e emisa, 'me valve ea ho laolla e theoha ka nako e le' ngoe.Ha khatello ea oli tseleng e theoha ka tlase ho 0.2Mpa, lubricator ea bongata e qala ho tlatsa ntlha ea ho tlotsa ebe e phethela ho tlatsa oli e le 'ngoe.Ka lebaka la phepelo e nepahetseng ea oli ea ente ea oli e ngata le ho lemoha khatello ea sistimi, phepelo ea oli e ea tšepahala, ho netefatsa hore ho na le filimi ea oli holim'a para e 'ngoe le e' ngoe ea kinematic, e fokotsa ho ferekana le ho roala, le ho thibela tšenyo ea li-kinematic. sebopeho sa ka hare se bakoang ke mocheso o feteletseng., ho etsa bonnete ba ho nepahala le bophelo ba Machine.Ha ho bapisoa le seporo sa tataiso e thellang, seporo sa mehala e tataisang se sebelisoang Mochineng ona se na le letoto la melemo:

① Kutloisiso ea ho sisinyeha e phahame, coefficient ea likhohlano tsa seporo sa seporo se nyane, ke 0.0025 ~ 0.01 feela, mme matla a ho khanna a fokotsehile haholo, a lekanang feela le 1/10 ea mochini o tloaelehileng.

② Phapang pakeng tsa khohlano e matla le e tsitsitseng e nyane haholo, 'me ts'ebetso ea ho latela e ntle haholo, ke hore, nako ea nako lipakeng tsa lets'oao la ho khanna le ketso ea mochini e khuts'oane haholo, e thusang ho ntlafatsa lebelo la karabo le kutlo. tsamaiso ea lipalo.

③ E loketse motsamao o tsamaeang ka lebelo le phahameng, 'me lebelo la eona hang-hang le phahame ka makhetlo a 10 ho feta la liporo tsa tataiso tse thellang.

④ E khona ho lemoha motsamao o se nang lekhalo le ho ntlafatsa ho sisinyeha ha motsamao oa mochini.

⑤E entsoe ke baetsi ba litsebi, e na le ho nepahala ho phahameng, ho feto-fetoha ha maemo le tlhokomelo e bonolo.

5.Tlhahlobo ea laser ea li-axis tse tharo:

Mochini o mong le o mong oa Bosman o lekantsoe ke laser interferometer ea k'hamphani ea RENISHAW United Kingdom ho hlahloba ka nepo le ho lefella phoso ea molumo, ho khutlela morao, ho nepahala ha boemo, ho pheta-pheta ho nepahala ha boemo, joalo-joalo, ho netefatsa botsitso bo matla, bo tsitsitseng le ho nepahala ha ts'ebetso ea mochini .Tlhahlobo ea Ballbar Mochini o mong le o mong o sebelisa bolo ea k'hamphani ea Brithani ea RENISHAW ho lekanya ho nepahala ha selikalikoe le ho nepahala ha mochine oa geometri, le ho etsa liteko tsa ho itšeha ka selikalikoe ka nako e le 'ngoe ho netefatsa ho nepahala ha 3D le ho nepahala ha selikalikoe sa mochine.

6.Tikoloho ea tšebeliso ea mochini:

6.1.Litlhoko tsa tikoloho ea tšebeliso ea lisebelisoa

Ho boloka boemo bo sa khaotseng ba mocheso oa tikoloho ke ntho ea bohlokoa bakeng sa ho sebetsa ka nepo.

(1) Litlhoko tse teng tsa mocheso oa tikoloho ke -10°C ho isa ho 35°C, ha mocheso o phelang o le 20°C, mongobo o lokela ho ba 40% ho isa ho 75%.

(2) E le ho boloka ho nepahala ho tsitsitseng ha Mochine ka har'a mefuta e boletsoeng, mocheso o motle oa mocheso o hlokahalang ho ba 15 ° C ho ea ho 25 ° C, 'me phapang ea mocheso e ke ke ea feta ± 2 ° C / 24h.

6.2.Matla a phepelo ea matla: mekhahlelo ea 3, 380V, ka har'a mefuta e fapaneng ea ± 10% ea ho fetoha ha motlakase, maqhubu a phepelo ea matla: 50HZ.

6.3.Haeba motlakase sebakeng sa ts'ebeliso e sa tsitsa, Mochini o lokela ho hlomelloa ka matla a tsitsitseng ho netefatsa ts'ebetso e tloaelehileng ea Mochini.

6.4.Mochini o lokela ho ba le motheo o tšepahalang: terata ea fatše ke terata ea koporo, bophara ba terata ha ea lokela ho ba ka tlase ho 10mm², 'me ho hanyetsa fatše ho lokela ho ba ka tlase ho 4 ohms.

6.5.E le ho netefatsa ts'ebetso e tloaelehileng ea ts'ebetso ea lisebelisoa, haeba moea o hatelitsoeng oa mohloli oa moea o sa khone ho finyella litlhoko tsa mohloli oa moea, sesebelisoa sa ho hloekisa mohloli oa moea (dehumidification, degreasing, filtering) se lokela ho ekeletsoa pele moea o kena. ea Mochini.

6.6.Beha lisebelisoa hole le khanya ea letsatsi, ho sisinyeha le mehloli ea mocheso, lijenereithara tse nang le maqhubu a phahameng haholo, metjhini ea welding ea motlakase, joalo-joalo, e le ho qoba ho hloleha ha tlhahiso ea Mochini kapa tahlehelo ea ho nepahala ha Mochini.

7.Technical parameters:

| Mohlala | 5020-5Z | |

| Boholo ba boholo ba mosebetsi oa ho sebetsa | Bolelele × bophara × bophahamo (mm) | 5000×2000×2500 |

| Phepelo e phahameng ea Gantry | Bophara (mm) | 2300 |

| boholo ba deske e sebetsang | Bolelele X Bophara (mm) | 5000*2000 |

| Tafole leeto | Bench ea mosebetsi e ea pele le morao (mm) | 5000 |

| Phahamisetsa pheleu habeli holimo le tlase | Ho otla holimo le tlase ho pheleu (mm) | 2500 |

| Horizontal pheleu mofuta oa ho phunya hlooho matla hlooho e 'ngoe tse peli | Bongata (2) | 2 |

| Horizontal pheleu mofuta oa ho phunya hlooho matla hlooho e 'ngoe tse peli | Spindle taper | BT50 |

| Lebelo la spindle (r/min) | 30 ~ 5000 | |

| Servo spindle motor power (kw) | 37*2 | |

| Sebaka se pakeng tsa litsi tsa nko ea li-spindle tse peli (mm) | 1500-2500 limilimithara | |

| Leqeba le letšehali le le letona la pheleu e le 'ngoe (mm) | 500 | |

| Leqeba le letšehali le le letona la pheleu e habeli (mm) | 1000 | |

| Ho Nepaha ha Boemo ba Bidirectional | 300mm * 300mm | ±0.025 |

| Ho nepahala ho pheta-pheta maemo a mabeli | 300mm * 300mm | ±0.02 |

| Boima ba 'mele (t) | (hoo e ka bang) 55 | Boima ba 'mele (t) |