BOSM -Horizontal Counter Drilling and Boring Machine

1. Tšebeliso ea lisebelisoa:

Mochini oa ho cheka oa BOSM o otlolohileng le o borata ke Mochini o ikhethileng bakeng sa k'hamphani ea hau ho sebetsana le likatiba tsa crane tora. Mochini o na le lisebelisoa tse 2 tsa ho cheka tse otlolohileng le lihlooho tsa matla a boreleli, tse ka hlokomelang ho cheka, ho sila le ho tena lisebelisoa tsa mosebetsi ka har'a mefuta e sebetsang ea stroke. Ho khaola le lisebelisoa tse ling, lebelo la ho beha thepa le potlakile, ho nepahala ha ho sebetsa ho phahame, 'me katleho ea ho sebetsa e phahame.

2. Litšobotsi tsa sebopeho sa lisebelisoa:

2. 1. Likarolo tse ka sehloohong tsaMochini

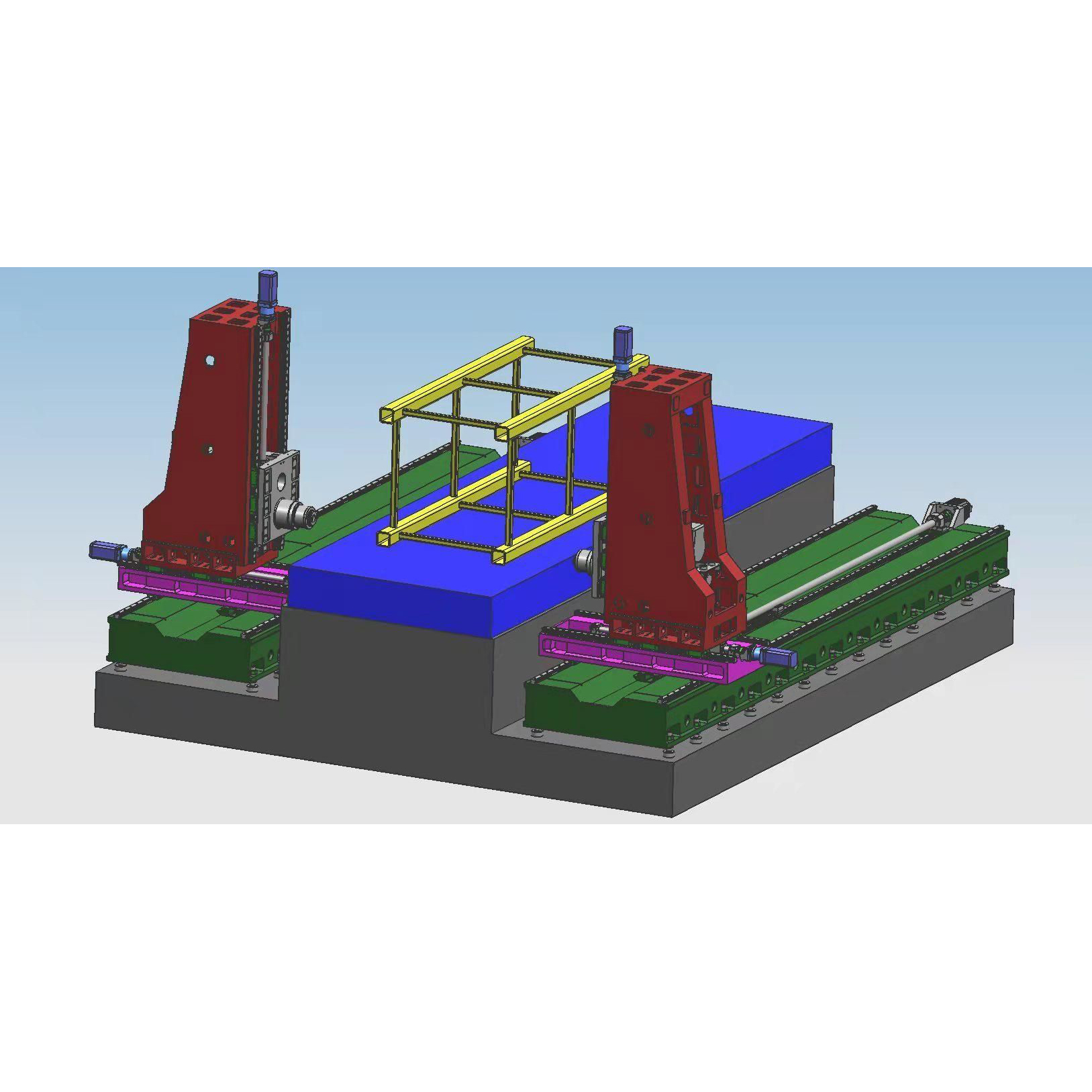

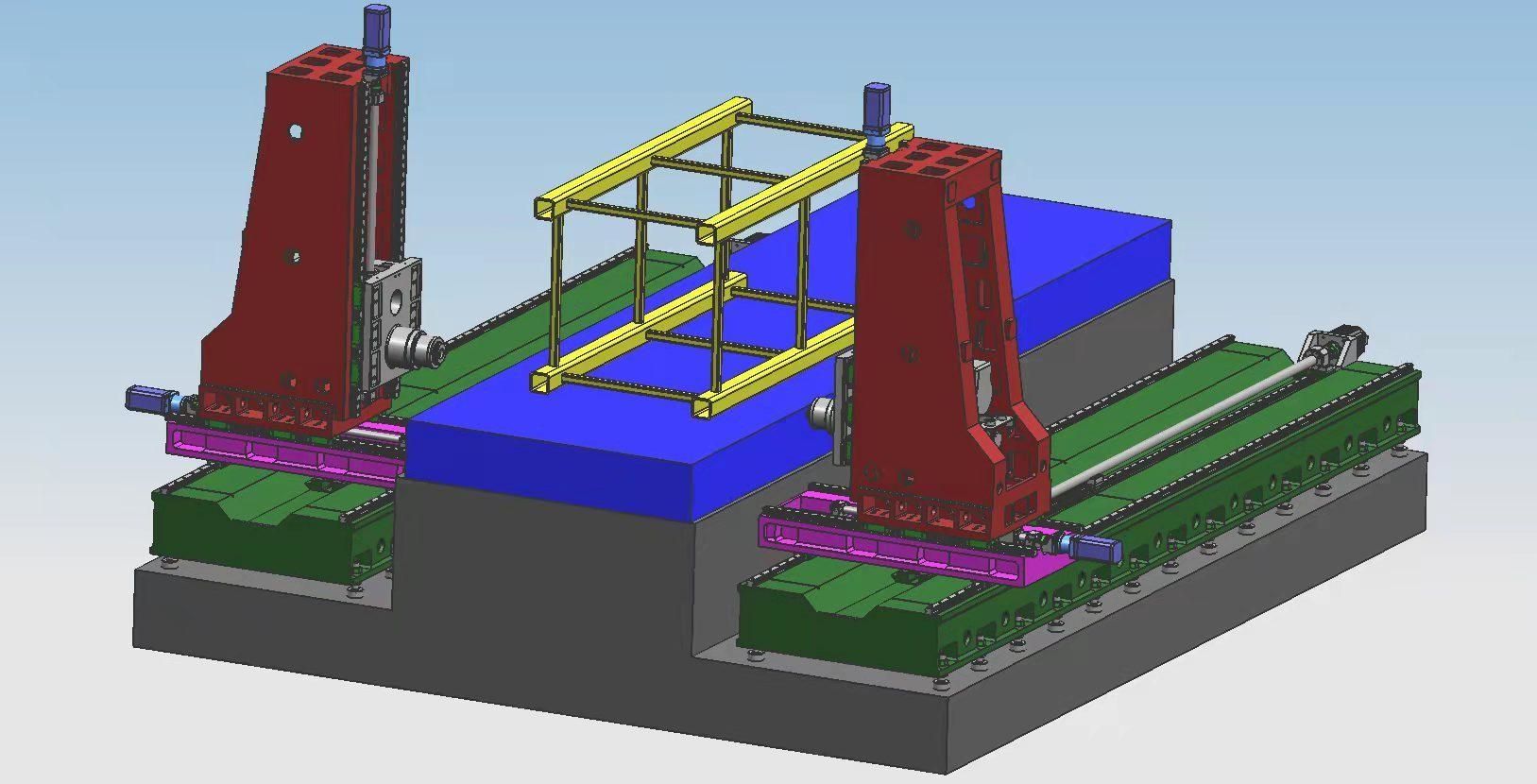

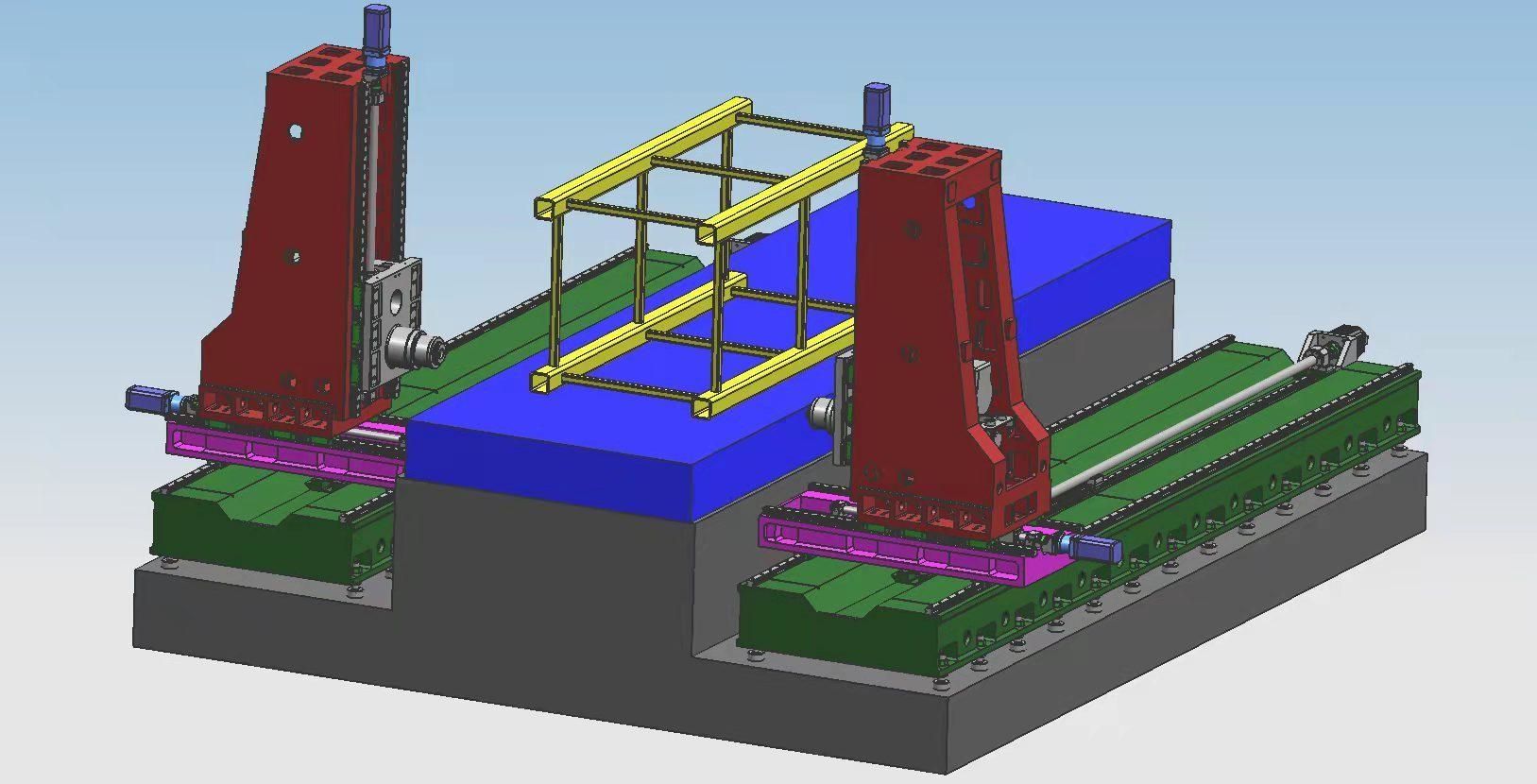

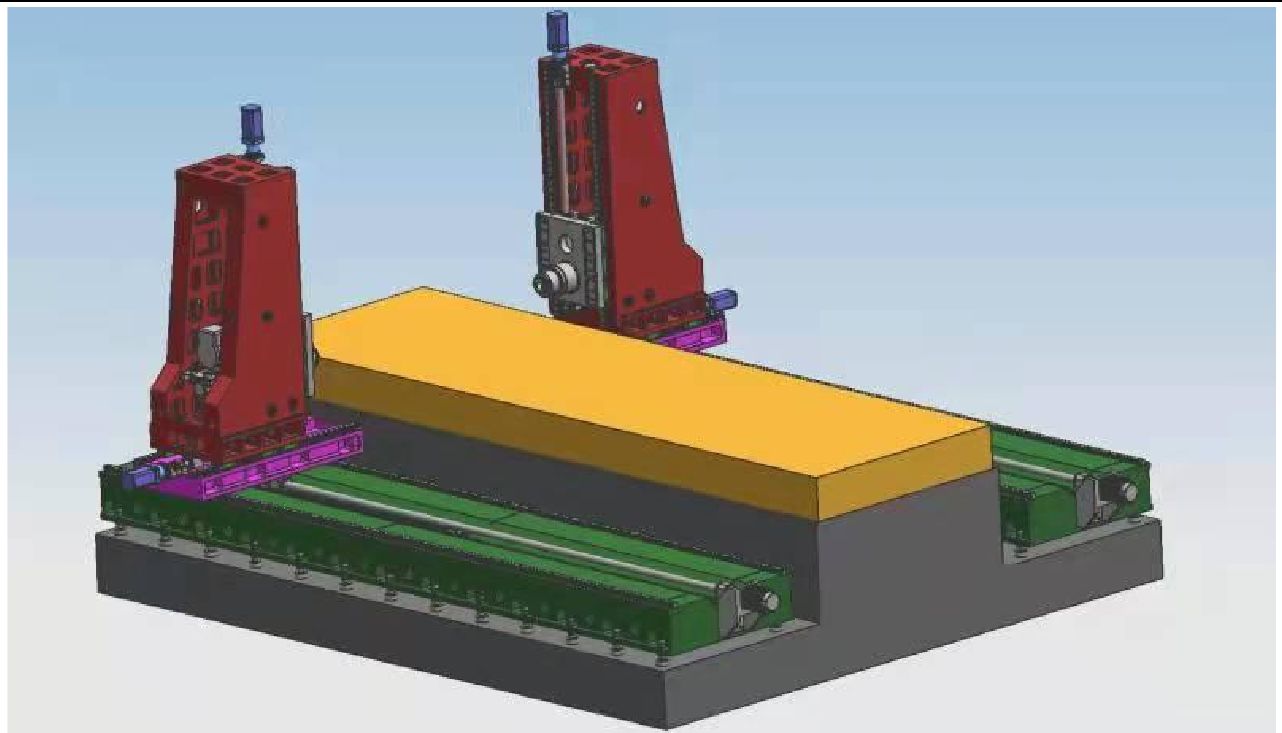

Likarolo tsa mantlha tsa Mochini: bethe, tafole ea ho sebetsa, litšiea tse ka ho le letšehali le tse ka ho le letona, liseile, lipheleu, joalo-joalo, likarolo tse kholo li entsoe ka mochini oa lehlabathe la resin, tšepe ea boleng bo holimo ea 250, e koaletsoeng ka sekoting sa lehlabathe le chesang → ho tsofala ho sisinyeha → ho chesa ho chesoa ha sebōpi → botsofali ba ho sisinyeha → ho sebetsa ka thata → botsofali ba ho sisinyeha → ho chesa sebōpi → botsofali ba ho sisinyeha → ho qeta ho felisa ka ho feletseng khatello e mpe ea likarolo le ho boloka tšebetso ea likarolo e tsitsitse. Sebaka sa ho sebetsa sa lisebelisoa se tsitsitse, 'me lihlooho tsa matla ka mahlakoreng ka bobeli li ka tsamaea ka pele le ka morao ea motheo; Mochini o na le mesebetsi e kang ho phunya, ho bora, ho qoelisa, ho tlanya, joalo-joalo Mokhoa oa ho pholisa oa sesebelisoa ke ho pholisa ka hare hammoho le ho pholisa ka ntle. Mochini o na le lilepe tse 5 tsa phepelo, lihlooho tse 2 tsa matla tse sehang, tse ka hokahanngoang le lilepe tse 5 ka nako e le 'ngoe, kapa e ka ba ntho e le 'ngoe feela. Tataiso ea axial ea Mochini le hlooho ea matla e bontšitsoe setšoantšong se ka tlase.

2. 2 Sebopeho se seholo sa karolo ea phepelo ea phepelo ea axial

2.2.1 X axis: Hlooho ea matla e khutlela morao ka thōko ho seporo sa tataiso ea motheo.

X1-axis drive: AC servo motor hammoho le mochini o fokotsang polanete o nepahetseng haholo o sebelisoa ho khanna hlooho ea matla ka har'a bolo ea screw drive ho lemoha motsamao oa mola oa X-axis.

Phetisetso ea X2-axis: AC servo motor hammoho le mochini o fokotsang polanete o nepahetseng haholo o sebelisoa ho khanna hlooho ea matla ka phetiso ea screw ea bolo ho lemoha motsamao oa X-axis linear.

Foromo ea seporo sa tataiso: Lithaele tse peli tse matla tse phahameng tse nepahetseng li kentsoe lithaele holim'a motheo o atolositsoeng.

2.2 Y1 axis: Hlooho ea matla e khutlela holimo le tlase kholomong.

Y1-axis drive: Adopt AC servo motor ho khanna ka har'a screw screw ho hlokomela motsamao oa Y1-axis. Foromo ea terene ea tataiso: likotoana tse 4 tsa mefuta e 45 ea mela e tataisang.

2.2.3 Y2 axis: Hlooho ea matla e khutlela holimo le tlase kholomong.

Phetisetso ea Y2-axis: AC servo motor e sebelisoa ho khanna ka har'a screw screw ho hlokomela motsamao oa mela ea Y1-axis.

Foromo ea terene ea tataiso: likotoana tse 4 tsa mefuta e 45 ea mela e tataisang.

2.2.4 Z1 axis: Hlooho ea matla e khutlela morao le morao holim'a sale.

Phetisetso ea Z1-axis: AC servo motor le mochini o fokotsang lipolanete tse nepahetseng haholo li sebelisoa ho khanna motsamao ka screw screw ho hlokomela motsamao oa mola oa Z1-axis.

2.2.5 Z2 axis: Hlooho ea matla e khutlela morao le pele holim'a sale.

Phetisetso ea Z2-axis: Enjene ea servo ea AC le mochini o fokotsang lipolanete tse nepahetseng haholo li sebelisoa ho khanna motsamao ka screw screw ho hlokomela motsamao oa mola oa Z2-axis.

2.3. Ho tlosoa ha chip le ho pholile

Ho na le li-conveyors tse bataletseng tsa ketane e kentsoeng ka mahlakoreng ka bobeli tlasa benche ea mosebetsi, 'me litsupa tsa tšepe li ka lahleloa ka har'a mochini o tsamaisang chip qetellong ho fihlela tlhahiso e tsoetseng pele. Ho na le pompo e pholileng ka har'a tanka e pholileng ea chip conveyor, e ka sebelisetsoang ho pholisa ka hare + ho pholisa ka ntle ho sesebelisoa ho netefatsa ts'ebetso le bophelo ba ts'ebeletso ea sesebelisoa, 'me pholiso e ka sebelisoa hape.

3. Sistimi e felletseng ea taolo ea linomoro tsa dijithale:

3.1. Ka ts'ebetso ea ho pshatla ha chip, nako ea ho robeha ha chip le potoloho ea ho robeha ha chip e ka beoa sebopehong sa mochini oa motho.

3.2. Ka ts'ebetso ea ho phahamisa lisebelisoa, sebaka sa ho phahamisa sesebelisoa se ka beoa sebopehong sa mochini oa motho. Ha sebaka se fihla, sesebelisoa se tla phahamisoa ka potlako, ebe li-chips li tla lahleloa, ebe li potlakela ho ea sebakeng sa ho phunya ebe li fetoloa ka bo eona ho sebetsa.

3.2. Lebokose la taolo ea ts'ebetso e bohareng le yuniti e ts'oaroang ka letsoho e amohela sistimi ea taolo ea linomoro 'me e na le sebopeho sa USB le ponts'o ea kristale ea metsi ea LCD. E le ho nolofatsa mananeo, polokelo, pontšo le puisano, sebopeho sa ts'ebetso se na le mesebetsi e kang puisano ea mochine oa motho, matšeliso a phoso, le alamo e ikemetseng.

3.2 .. Thepa e na le mosebetsi oa ho hlahloba le ho hlahloba hape sebaka sa sekoti pele se sebetsa, 'me ts'ebetso e bonolo haholo.

4. Lubrication e iketsang

Lipara tsa literene tse nepahetseng tsa mochini, li-screw screw pairs le lipara tse ling tse tsamaeang hantle haholo li na le lisebelisoa tsa boiketsetso. Pompo e itšebetsang e hlahisa oli ea khatello, 'me kamore ea oli ea lubricator e kenang ka har'a oli. Ha kamore ea oli e tletse oli 'me khatello ea tsamaiso e nyolohela ho 1.4 ~ 1.75Mpa, mochine oa khatello tsamaisong o koetsoe, pompo e emisa,' me valve ea ho laolla e laolloa ka nako e le 'ngoe. Ha khatello ea oli tseleng e theoha ka tlase ho 0.2Mpa, lubricator ea bongata e qala ho tlatsa ntlha ea ho tlotsa ebe e tlatsa ho tlatsa oli e le 'ngoe. Ka lebaka la palo e nepahetseng ea oli e fanoang ke oli ea bongata le bokhoni ba ho bona khatello ea sistimi, phepelo ea oli ea tšepahala ebile e netefatsa hore ho na le filimi ea oli holim'a para e 'ngoe le e' ngoe ea kinematic, e fokotsang likhohlano le ho roala le ho thibela tšenyo. ho sebopeho sa ka hare se bakoang ke mocheso o feteletseng. , ho etsa bonnete ba ho nepahala le bophelo ba Machine.

5. Mochinitikoloho ea tšebeliso:

Phepelo ea matla: Mehato e meraro AC380V±10%, 50Hz ± 1 mocheso oa tikoloho: -10°~ 45°

6. Mekhoa ea ho amohela:

JB/T10051-1999 "Tlhaloso e Akaretsang ea Tekheniki bakeng sa Hydraulic System ea Mechini ea ho Seha Metal"

7. Litekanyetso tsa tekheniki:

| Mohlala | 2050-5Z | |

| Boholo ba boholo ba mosebetsi oa ho sebetsa | Bolelele × bophara × bophahamo (mm) | 5000×2000×1500 |

| boholo ba deske e sebetsang | Bolelele X Bophara (mm) | 5000*2000 |

| Maeto a tataiso ea hlooho ea matla a matla | Tsamaea pele le morao (mm) | 5000 |

| Matla a hlooho holimo le tlase | Ho otla holimo le tlase ho pheleu (mm) | 1500 |

|

Mofuta oa pheleu o otlolohileng oa ho cheka hlooho ea matla Matla a hlooho 1 2 | Bongata (2pcs) | 2 |

| Spindle taper | BT50 | |

| Bophara ba ho cheka (mm) | Φ2-Φ60 | |

| Bophara ba ho tlanya (mm) | M3-M30 | |

| Lebelo la spindle (r/min) | 30-3000 | |

| Servo spindle motor power (kw) | 22*2 | |

| Leeto le letšehali le le letona (mm) | 600 | |

| Ho Nepaha ha Boemo ba Bidirectional | 300mm * 300mm | ±0.025 |

| Ho nepahala ho pheta-pheta maemo a mabeli | 300mm * 300mm | ±0.02 |